Breaking Barriers in Manufacturing with Hydraulic Press for Large Parts

Across the globe, manufacturers are under constant pressure to produce larger components at higher speeds – without inflating costs. This balancing act is no small feat, especially as industries demand stronger, more complex parts. Fortunately, hydraulic press for large parts technology is transforming the game. These machines apply consistent, powerful force across expansive working surfaces, enabling the efficient forming of oversized and high-strength components.

Unlike traditional mechanical systems, modern hydraulic presses handle diverse materials and shapes with ease, all while maintaining exceptional accuracy and repeatability. Even more impressive, they do it with reduced energy consumption and minimal noise. From heavy-duty automotive parts to wind turbine hubs and industrial machinery frames, these presses are helping manufacturers break through old limitations. With faster setup, intelligent control systems, and lower maintenance demands, hydraulic presses for large parts deliver a perfect blend of performance, precision, and sustainability – making them a must-have in today’s competitive manufacturing landscape.

Why Large-Scale Pressing Matters

Global demand for heavy-duty parts is soaring. Wind-turbine hubs, truck frames, and construction plates keep getting larger. Traditional mechanical presses struggle with these sizes. A hydraulic press for large parts fills the gap because:

• It applies full tonnage across the entire stroke.

• It adapts to complex dies without re-tooling.

• It supports repeatable accuracy even at extreme loads.

That flexibility cuts downtime. It also opens doors to new alloys and wider product lines. In short, large-scale pressing is now the backbone of modern heavy fabrication.

Meet Guangduan

I am proud to introduce Guangduan, one of Asia’s leading forging and pressing enterprises. We have spent more than half a century refining hydraulics, controls, and safety systems. Our factory floor houses advanced CNC centers, Robotic welding stations, and a strict quality lab.

We follow a clear creed:

✅ System management keeps every process traceable.

✅ Innovation drives fresh ideas from concept to prototype.

✅ Elaborate manufacturing ensures tight tolerances on every beam.

✅ Quality service means responsive after-sales support.

Thanks to this culture, we hold dozens of patents for servo control and oil-circuit design. Yet we never stop learning. Each press we ship is a promise of performance and longevity.

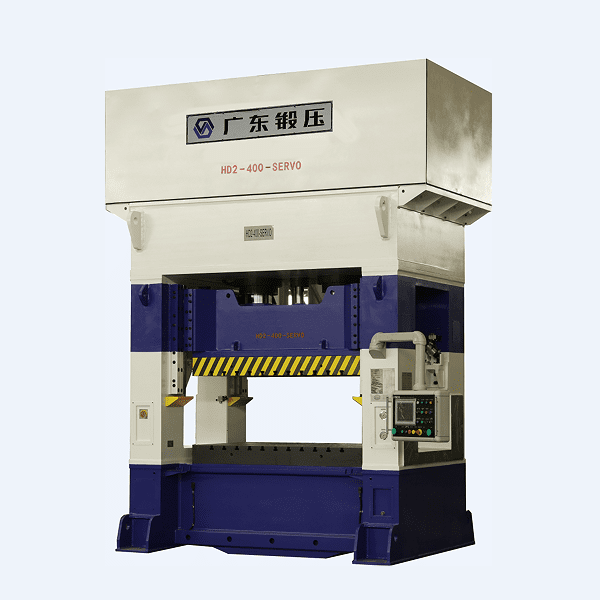

Inside the GY2S Series

At Guangduan, we’ve engineered the GY2S Series Hydraulic Press for Large Parts to meet the demands of modern manufacturing – where strength, accuracy, and control are non-negotiable. This flagship series combines a rugged mechanical structure with advanced servo intelligence, making it ideal for forming oversized components across automotive, energy, construction, and appliance industries.

Key Structural and Functional Highlights

✅ Box-Welded Steel Frame

The GY2S frame is built from high-grade steel plates welded into a sealed box structure. This design offers superior rigidity and minimizes deflection under heavy loads. The smooth contours also make the press easier to transport and install, reducing setup time and risk of damage.

✅ Eight-Sided Slide Guidance

The ram is supported by a precision-guided system along eight surfaces, maintaining perfect alignment throughout the stroke. This reduces wear and guarantees long-term accuracy, even under continuous, high-load operations.

✅ Thin-Oil Circulation Lubrication

A continuous thin-oil lubrication system reduces internal friction, keeps temperature stable, and improves the overall life of mechanical components. This feature ensures smoother operation and consistent part quality over time.

✅ Servo Closed-Loop Control System

Equipped with a high-performance servo motor, pressure sensor, and PLC, the press monitors every movement in real time. The system corrects minor deviations within milliseconds – perfect for deep-drawing or high-precision forming of large parts.

✅ Touchscreen Interface with Smart Memory

Operators can program and store up to 20 sets of mold parameters through an intuitive touchscreen interface. Speed, pressure, and dwell time can be adjusted with just a few taps, allowing for quick changeovers and error-free production. With pressing capacities ranging from 2,000 kN to 20,000 kN, the GY2S series is built to handle a wide range of heavy-duty forming tasks with precision and efficiency.

Smart Servo Technology

Our use of servo motors redefines what a hydraulic press for large parts can do. Unlike traditional systems that run pumps at constant speed, our servo-driven units adjust flow on demand. This smart energy management system delivers several advantages:

✅ Energy Savings – Cuts power consumption by up to 50% versus fixed-pump systems

✅ Low Noise – Sound levels stay under 75 dB, making for a quieter, safer workspace

✅ Rapid Response – Delivers full pressing force in under 0.1 seconds

✅ Precise Holding – Adjustable dwell pressure minimizes springback and distortion

Moreover, each stroke is tracked and logged. This data powers predictive maintenance tools, helping operators catch issues early and reduce unplanned downtime.

Safety and Sustainability: Engineered for Peace of Mind

We take operator safety and environmental responsibility seriously. That’s why the GY2S integrates protective features at every level:

• Slider Locking Mechanism – Prevents unexpected movement during maintenance or die changes

• Two-Hand Control – Eliminates the chance of accidental activation

• HMI Safety Interlocks – Detect incorrect parameter settings before the machine cycles

• Eco-Friendly Hydraulic Fluids – Reduce environmental impact and prolong seal life

Our hydraulic press for large parts is fully compliant with CE and ISO safety standards. Optional features like light curtains, perimeter safety fences, and RFID-enabled die recognition further enhance operator protection and production integrity.

Industries That Benefit

A wide range of sectors already rely on Guangduan presses:

• Wind Energy: Short cycle times let towers and nacelle components ship faster, helping meet renewable targets.

• Automotive & EV: Large battery trays, chassis rails, and truck frames demand tight dimensional control. The GY2S delivers it without excess scrap.

• Construction Machinery: Boom plates and housing parts reach record sizes. Our press table spans them with room to spare.

• Appliance & White Goods: Deep-drawn washer drums and refrigerator panels leave the die smooth, reducing post-finish work.

Each industry values different features, yet all share one goal: consistent, high-volume output.

Innovating Beyond the Press

We see three trends shaping the next decade:

• Digital twins: Simulate stress and oil flow before a machine is built.

• Adaptive forming: Sensors inside the die adjust pressure in real time for mixed-gauge blanks.

• Green hydraulics: Bio-based fluids and energy-recovery circuits cut CO₂ footprints even further.

At Guangduan, we are already pilot-testing these ideas. Our R&D team partners with universities and global suppliers to speed up breakthroughs. The mission is simple: keep breaking barriers with every new hydraulic press for large parts we introduce.

Conclusion

The era of oversized components is here. Success hinges on equipment that can press, form, and finish without compromise. A Hydraulic press for large parts – especially the Guangduan GY2S Series – stands ready to meet that challenge. We invite manufacturers worldwide to join us, explore our demo center, and unlock their next wave of productivity.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us