Why Choose an Industrial Hydraulic Press for Precision Forming

An Industrial Hydraulic Press is the quiet muscle behind precise metal forming. It uses hydraulic power to apply controlled force with clean, repeatable motion. Frames stay rigid. Slides track straight. Sensors watch every stroke. Operators set pressure, speed, and position on a clear screen. Parts come out consistent, shift after shift. But not all presses deliver the same accuracy, safety, or energy use. Small design choices make a big difference on the shop floor. Why do some lines hit tolerance and others chase rework? And which features actually matter for precision forming? Let’s unpack the answers.

Built For Stable Accuracy

Forming precision starts with a body that does not move when the load rises. We use a welded box frame made from high-quality steel to lock out twist and sag under pressure. The geometry stays true, so the force you specify reaches the part without bending the line of action. That same box construction gives the press a compact, clean profile that is easier to place and relocate on a busy factory floor.

The slide matters just as much. Our slide is a welded box component guided on eight full-length rails. With guidance on all sides, the slide resists tilting and lateral wander, which are common causes of edge burrs, uneven thickness, and accelerated die wear. Because alignment holds, top and bottom tools meet squarely – even when the job runs through heat cycles and long hours.

Smooth motion requires consistent lubrication. A thin-oil, continuous-circulation system feeds fresh oil to the guides and slide, flushes contaminants, and stabilizes temperature. Operators feel the benefit as a “glass-like” stroke with less chatter. Maintenance teams see it in measured wear, predictable service intervals, and cleaner audits.

What this looks like on your parts:

• Fewer off-center hits, which means lower die stress and tighter dimensions.

• Less rework on tight-tolerance parts because alignment stays locked in.

• A quieter, low-vibration cell that supports higher nearby equipment uptime.

Intelligent Control You Can Trust

An Industrial Hydraulic Press should do more than move a ram. It should confirm that every cycle follows the recipe. Our servo closed-loop architecture pairs a servo driver with pressure and displacement sensors, all coordinated by a PLC. During each stroke, the system compares commanded force and position with actual values and corrects in real time. This keeps profiles tight, avoids overshoot, and reduces heat buildup – especially valuable on long production runs.

Setup is straightforward. The HMI combines a touch screen with a high-resolution grating ruler (precision scale). You set force, speed, dwell, and position digitally. Live values remain visible while the cycle runs, so supervisors and technicians can verify performance at a glance. To accelerate changeovers, up to 20 parameter sets can be stored and recalled. Load the next tool, choose the saved recipe, confirm limits, and you’re producing – no paper notes taped to the screen and no guesswork.

Noise and vibration have been engineered down at the source. By eliminating sudden hydraulic shocks and matching output to real demand, the press runs smoother and uses less energy. Those incremental savings add up across three shifts and multiple machines, helping you hit quality targets without inflating your utility bill.

Where manufacturers see the biggest gains:

• Automotive brackets and chassis inserts where flatness and hole location stack across assemblies.

• Consumer-electronics shells that demand crisp edges and minimal springback.

• Appliance sheet components that must pass cosmetic checks straight off the tool.

If your engineers measure in microns but adjust by instinct, this control loop closes the gap. It gives process owners clean data, lets supervisors predict output, and gives operators a simple, repeatable workflow.

Safety And Uptime By Design

Downtime is more than lost minutes – it is missed truck slots, idle feeders, and rescheduled shifts. Our Industrial Hydraulic Press integrates multi-layer protection to keep people safe and production on pace. A mechanical slider-locking device can secure the slide at any position for maintenance or unexpected stops. Electrical and logic safeguards add redundancy: a lower-limit switch to prevent over-travel, two-hand anti-repeat to stop accidental double-cycling, and parameter anti-error checks on the touch screen to catch out-of-range settings before they reach the machine.

These safeguards protect your most expensive tooling. Over-stroke events and misalignment crashes are the fastest way to destroy a schedule. By preventing them, the press helps you protect die investments and keep promises to customers. When service is needed, lockable mechanics and clear diagnostics reduce mean time to repair. Crews get in, correct, and return to production quickly – without compromising safety.

The same features that make the press safe also make it consistent. A rigid frame resists drift, full-surface guidance maintains alignment, and servo closed-loop control repeats the profile you specify. That is how you hold tolerance through seasonal temperature swings and shift changes without constant tweaking. It also shortens the learning curve for new operators: start with a stable machine, train on clear steps, and confidence grows fast.

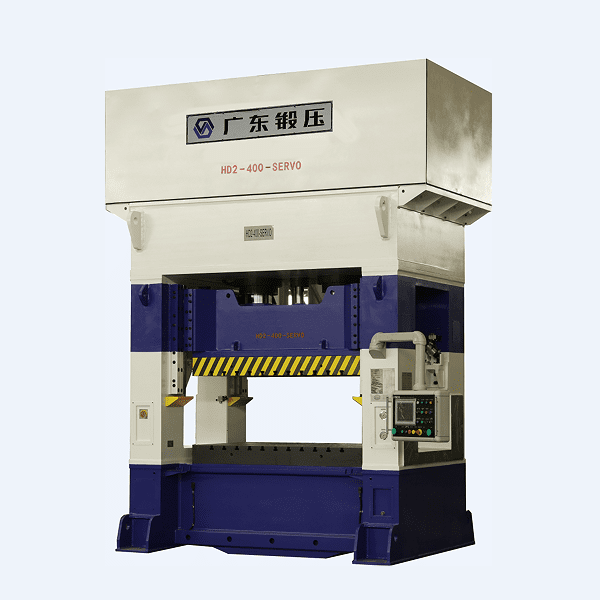

ü Why Teams Choose Guangduan

We focus on the details that matter day after day on the shop floor:

• Rigid Welded Box Frame – maintains geometry under load for durable, dimensional stability.

• Eight-Sided Full Guide Rails – protect dies and preserve long-term precision retention.

• Thin-Oil Continuous Lubrication – reduces friction, stabilizes temperature, and simplifies maintenance.

• Servo Closed-Loop Control – real-time correction with pressure and displacement feedback for high accuracy and lower energy use.

• Operator-First HMI – touch-screen setup, grating-ruler feedback, and 20 recipe slots for faster changeovers.

• Layered Safety – slider lock, lower-limit protection, two-hand anti-repeat, and on-screen parameter checks.

Each of these choices supports a simple goal: predictable quality with fewer surprises. When a press behaves the same way on the first stroke and the ten-thousandth, planning gets easier, costs go down, and customers notice the difference.

ü Practical Tips For A Better ROI

To maximize the value of any Industrial Hydraulic Press, align the machine’s strengths with your process realities:

• Qualify a reference recipe. Use the saved parameters feature to lock in a “golden run” for your highest-volume parts.

• Watch the data, not just the parts. Trend pressure-position curves to catch drift days before it shows up in inspection.

• Schedule lubrication checks. Continuous circulation simplifies life; a short audit keeps the system at peak efficiency.

• Train to the HMI. Short, hands-on sessions help operators read live values and react with confidence rather than over-adjusting.

² Talk To Us About Your Line

If you are chasing tighter tolerances, lower scrap, or a calmer, quieter cell, Guangduan can help you specify the right Industrial Hydraulic Press for your forming line. Share your part drawings, materials, and takt time, and we’ll return a tailored configuration, sample cycle data, and a clear path to raise quality while cutting risk.

Call to Action: Ready to stabilize precision forming and protect your dies? Contact Guangduan for an application review and a press proposal aligned to your throughput and tolerance goals.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us