How the Automatic Forging Press Fits into Industry 4.0

Industry 4.0 is reshaping factory floors across the globe. Robots weld, sensors listen, and data flows in real time. Yet one machine often overlooked in this digital rush is the Automatic Forging Press. Built to deliver raw power, it now sits at the crossroads of tradition and innovation. As manufacturers worldwide pivot toward Industry 4.0, machinery must evolve from simple mechanical tools into intelligent systems capable of seamless integration, data analysis, and automation. This is where we, Guangduan, as a leading manufacturer in forging solutions, take pride in being at the forefront of innovation.

The Role of the Automatic Forging Press in Modern Manufacturing

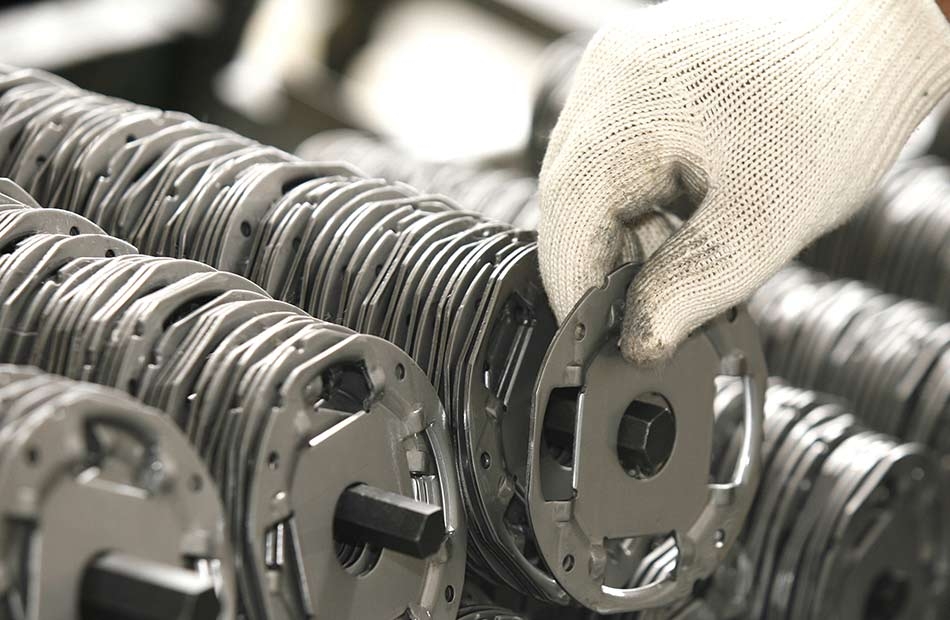

The Automatic Forging Press plays a critical role in shaping metal components with precision and consistency. Its ability to perform high-speed, automated operations makes it ideal for mass production in various industries, including:

✅ Automotive manufacturing

✅ Aerospace and defense

✅ Consumer electronics

✅ Hardware and home appliances

At Guangduan, our JH31 Series – a closed type, single-point press – is designed with Industry 4.0 in mind, ensuring smarter, safer, and more connected operations.

Understanding the JH31 Series: Built for Smart Factories

Compact Yet Powerful Structure

The JH31 Series Automatic Forging Press features a monolithic box-type structure that delivers:

• Exceptional rigidity for stability during high-pressure operations

• Enhanced durability through precision CNC-machined components

• Streamlined design for space-efficient factory layouts

Some models in this series use a four-pull level pre-light structure for added strength. Whether you’re forging complex automotive parts or high-volume consumer products, structural integrity is essential for repeatability and accuracy.

Intelligent Mechanical Systems

The JH31 Series is not just built tough – it’s built smart. Key mechanical innovations include:

• Digitally displayed mechanical die set height adjustment

• Quick and easy die calibration

• Wet-type clutch for long service life and strong bearing capacity

• Four-surface full-guideway slide block for superior guiding precision

These features contribute to a significant reduction in downtime and setup time, ensuring better productivity.

Seamless Integration with Industry 4.0

Our Automatic Forging Press is built for the smart factory era. It connects machines, data, and people in real time. By adding intelligence to every ram stroke, we turn a once-isolated forge into a fully networked production node.

Smart Control and Monitoring

Guangduan equips each press with a layered control stack that keeps operations agile and safe.

✅ PLC-based logic – operators choose, store, and repeat job recipes with a few clicks.

✅ Pneumatic actuation – fast, smooth responses ensure tight cycle times and stable force delivery.

✅ Photo-electric guards – light curtains create an instant safety envelope around the die area.

✅ Automatic feeders & uncoilers – coil stock moves straight from roll to die without manual touch.

These tools let technicians monitor speed, load, temperature, and clutch status from a browser or shop-floor tablet. Remote tweaks take seconds, not hours, and visual alarms appear the moment a parameter drifts.

Data-Driven Production

In Industry 4.0, data is the new lubricant. Every Guangduan press streams performance figures through open protocols that link to MES and ERP platforms.

• Predictive maintenance – vibration and oil-pressure trends flag wear before it becomes downtime.

• Quality dashboards – stroke-by-stroke force curves trace part conformity in real time.

• Live OEE reports – availability, performance, and quality metrics update on a single screen.

• Auto-scheduling – the press shares run status with planning software, letting planners balance line capacity on the fly.

With smart sensors at each joint and bearing, the Automatic Forging Press no longer hides its condition behind steel. It becomes an active voice in the digital conversation, helping teams cut scrap, save energy, and ship parts on schedule. By merging rugged hardware with cloud-ready analytics, we create a forging solution that fits seamlessly into any Industry 4.0 roadmap – today and tomorrow.

Broad Applications Across Industries

Our JH31 Series Automatic Forging Press is designed for flexibility and performance, making it a reliable choice across a wide range of industries.

• Automotive & Motorcycle Manufacturing

Ideal for forging gear components, transmission housings, and structural brackets with high accuracy and strength.

• Daily Hardware Production

Efficiently handles the shaping of tools, hinges, handles, and metal frames used in household and industrial products.

• Gas Appliances Industry

Produces valves, fittings, and connectors that demand tight tolerances and consistent quality.

• Instrumentation & Electronics

Perfect for precision parts such as sensor housings, metal enclosures, and delicate structural components.

This wide applicability helps businesses scale faster, diversify product lines, and remain competitive in demanding markets.

Safety and Reliability Built In

At Guangduan, we place safety and long-term reliability at the core of every machine. Our Automatic Forging Presses include advanced protection features to ensure safe and efficient operation:

✅ Hydraulic overload protection (in JH31-400/630/800) prevents damage during sudden load spikes.

✅ Wedge-type die unlocking (in JH31-200-300) enables fast, secure tool changes.

✅ Photo-electric safety barriers guard the working zone to protect operators in real time.

These systems work together to reduce downtime, prevent accidents, and support consistent high-speed production – even in tough environments. Our goal is simple: to keep your production line moving safely and efficiently, day after day.

Why Choose Guangduan?

As an established manufacturer, we don’t just produce machines – we engineer solutions for the future of manufacturing. Here’s what sets us apart:

✅ Over 100 engineers and technicians with deep industry expertise

✅ Advanced R&D and testing capabilities, including 1,000+ sets of measurement instruments

✅ Nearly 100 sets of large-scale CNC equipment

✅ Headquarters in Shunde and full production control through our subsidiary Wuzhou Wanshun

Every Automatic Forging Press we build reflects decades of craftsmanship, innovation, and our commitment to driving digital transformation in manufacturing.

Forging the Future: Final Thoughts

As factories transform into intelligent systems under Industry 4.0, the Automatic Forging Press has evolved from a basic production tool into a smart manufacturing asset. With high precision, integrated control systems, and real-time connectivity, Guangduan’s JH31 Series is designed to meet the needs of the modern manufacturing era. In a world where flexibility, efficiency, and data are key, our Automatic Forging Press machines are not only keeping pace – they’re leading the way. Partner with us to unlock the full potential of smart forging technology.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us