Revving Up Efficiency with Smart Automotive Forging Press Technology

Efficiency is a top priority in today’s automotive manufacturing. Studies show that smart technologies can boost production efficiency by up to 25%. One tool making a big impact is the Automotive Forging Press.

These machines shape metal parts with high force. But now, they do much more. With smart sensors and real-time data, they help reduce waste and improve accuracy. This means fewer errors and stronger parts.

As car designs become more advanced, the demand for precision grows. Smart Automotive Forging Press systems meet this need with speed and reliability. In this article, we explore how these innovations are changing the game for car makers everywhere.

The New Era of Automotive Manufacturing Efficiency

The Industry Demand for Smarter Forging Solutions

The automotive industry is changing fast. Manufacturers want faster, safer, and more efficient production. As cars become lighter and more complex, traditional equipment can no longer meet these needs. This is where smart Automotive Forging Press technology steps in.

Automotive Forging Press: Core to Modern Production Lines

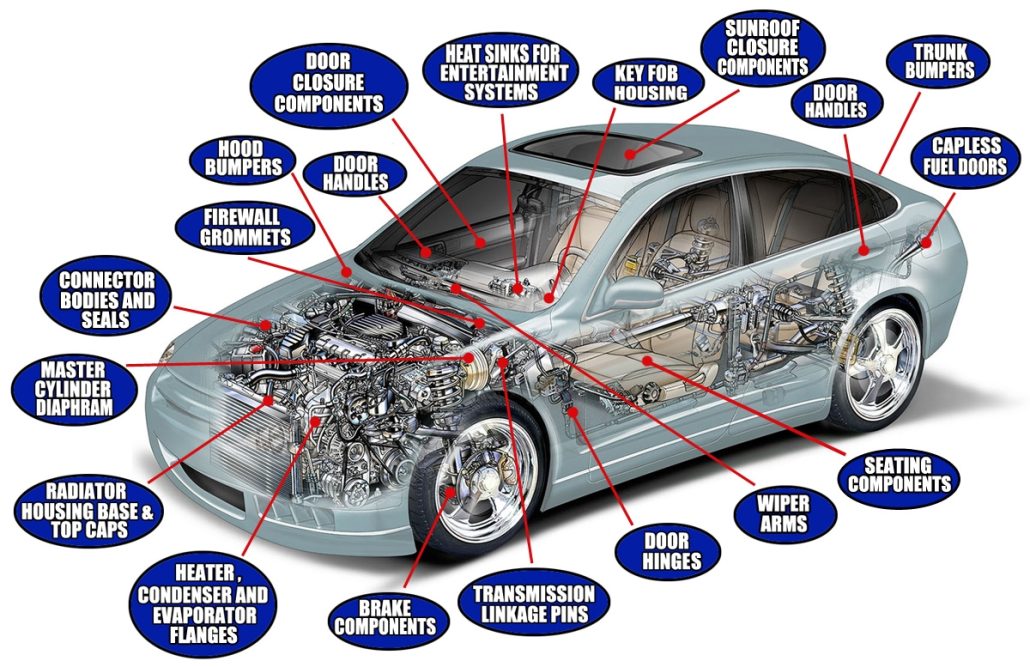

The Automotive Forging Press plays a key role in shaping metal parts. It helps create strong and precise components. These parts are used in everything from car bodies to engine parts. A high-quality press machine improves both product strength and production speed.

Smart Technology‘s Role in Boosting Output and Reducing Waste

Smart forging systems use sensors and digital controls. This means fewer errors and less material waste. With features like real-time monitoring and automatic adjustments, manufacturers can run smoother and safer operations. Smart presses also reduce downtime and energy costs.

GUANGDUAN: Pioneering Innovation in Forging Equipment

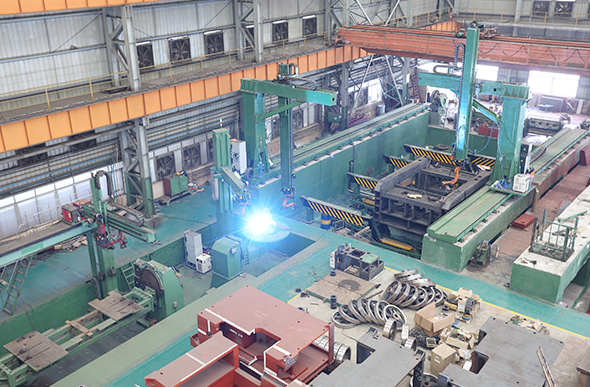

A Legacy of Excellence in South China Manufacturing

GUANGDUAN is a leading forging equipment manufacturer based in South China. For decades, we have focused on design, R&D, manufacturing, and service. We take pride in being one of the first companies in China’s forging industry to earn ISO9001 certification.

Certifications and National Recognition in the Forging Industry

Our company is recognized as a “National Backbone Enterprise for Forging Equipment.” We are also listed as a “National High-Tech Enterprise” and a “National Export Base.” These titles reflect our strong position in the industry and our commitment to quality.

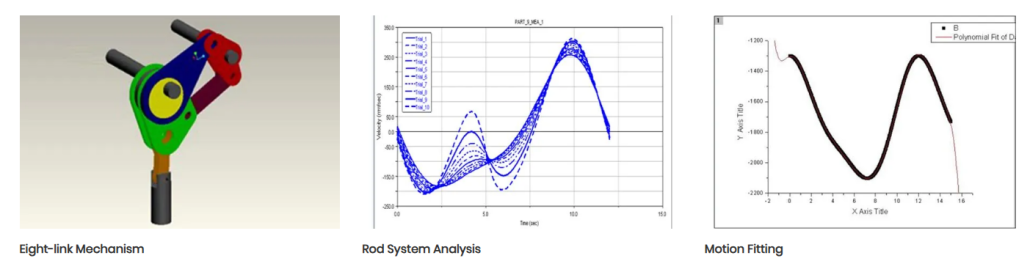

R&D Partnerships and Technological Collaboration with Leading Universities

We work closely with top universities like South China University of Technology. Together, we develop tools for accuracy analysis and dynamic testing. Our press systems are supported by ANSYS software to ensure strength and precision. These partnerships help us create better machines for the future.

JH31 Series: A High-Precision Forge Press Machine

Overview of the Closed Type Single Point Forge Press Machine

The JH31 Series Automotive Forging Press is built for precision and strength. It is a closed type, single-point press machine. It’s designed to handle a wide range of metal stamping tasks with high speed and accuracy.

Box-Type Body and Four-Pull Pre-Light Design

The body of the JH31 press uses a one-piece box-type structure. Some models include a four-pull pre-light structure. This design provides excellent rigidity and stability during heavy operation. It helps maintain precision even after long-term use.

Advantages of High Rigidity and Strong Crankshaft Bearing Capacity

The crankshaft is strong and durable. It uses an eccentric shaft type with a high bearing load. The wet-type clutch gives it a long service life. The four-surface full-guideway ensures smooth and precise slide motion. These features work together to boost performance and reduce wear.

Intelligent Control for Modern Production Lines

PLC and Pneumatic Integrated Control System

The Automotive Forging Press JH31 Series uses a combination of PLC and pneumatic control. This setup allows for smooth and stable machine operation. It also ensures fast response and precise control during the forging process. Operators can easily monitor and adjust the press in real time.

Multi-Mode Stroke Options

This machine supports three stroke modes. These include continuous stroke, single stroke, and micro-motion. Each mode is useful for different production needs. Operators can switch between modes quickly to improve efficiency and adapt to various forging tasks.

Optional Automation

For higher safety and speed, the JH31 Automotive Forging Press can be equipped with automation options. Photoelectric protection helps prevent accidents during operation. Auto feeding devices can be added to reduce manual work and support continuous production. These features make the production line more intelligent and safe.

Smart Features for Real-World Performance

Digital Die Set Height Adjustment and Fast Calibration

Setting the die height is simple and quick. The die height is shown on a digital display. Mechanical adjustments are smooth and fast. This feature saves time during tool changes and improves production flow.

Hydraulic Overload and Die Unlocking Safety Systems

Safety is important in any Automotive Forging Press. The JH31-400/630/800 models come with a hydraulic overload protection device. This system helps protect the press and tools from damage. The JH31-200-300 models use a wedge-shaped iron die unlocking device for easy and safe die removal.

Compact Layout and Ergonomic Design for Factory Environments

The JH31 press has a compact body and clean design. It fits well in modern factories with limited space. Its layout is logical and user-friendly. This makes maintenance easy and improves the working environment for operators.

Application Scope: Versatility Across Industries

Automotive and Motorcycle Component Manufacturing

The Automotive Forging Press is widely used to make car and motorcycle parts. These include engine brackets, frame pieces, and more. The JH31 Series provides the strength and accuracy needed for high-volume, high-quality part production.

Use Cases in Hardware, Gas Appliances, and Instrumentation

Beyond the automotive sector, the press is used in hardware, home appliances, and precision tools. It can handle different shapes and sizes of metal parts. Its flexibility makes it a good choice for many types of factories.

Customizable Setup for Press Lines and MES System Integration

We also offer custom press line setups. Machines can be connected in a series to create full production lines. Our presses can be linked with MES systems for smart factory management. This helps customers track production and improve overall efficiency.

Quality, Technology, and the Future of Forging

3D Digital Design and Modular Engineering with SOLIDWORKS

At GUANGDUAN, we use high-end 3D software like SOLIDWORKS. Our design process follows modular and serialized methods. This helps us shorten design time and improve the quality of each Automotive Forging Press we build.

Finite Element Analysis (ANSYS) for Structural Optimization

We use ANSYS software to test the press body under real working loads. This helps us find the best structure for each model. By running these simulations, we make sure every machine has strong rigidity and long-lasting precision.

Italian CMM and Swiss Laser Tracker

Quality control is a top priority. We use Italian-made Coordinate Measuring Machines and Swiss laser trackers to check accuracy. These tools allow us to measure large parts with high precision. They help us maintain strict quality standards for every machine we produce.

Schedule Your Demo and Start Forging Smarter

Discover how the JH31 Series Automotive Forging Press can boost your efficiency, precision, and safety. Whether you need smarter control, faster setup, or reliable performance, GUANGDUAN has the solution. Contact us today to learn more, request a quote, or schedule a demo. Let’s forge the future—together.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us