How to Master Automated Hydraulic Press

The automated hydraulic press is a staple in many manufacturing facilities. It’s a workhorse that can quickly and easily stamp out parts or products. But, as with any piece of equipment, it takes time and practice to master its use. In this blog post, we will explore how to master the automated hydraulic press. From loading the material to be stamped to setting the right pressure, we will cover everything you need to know to get the most out of this versatile machine.

What is an Automated Hydraulic Press?

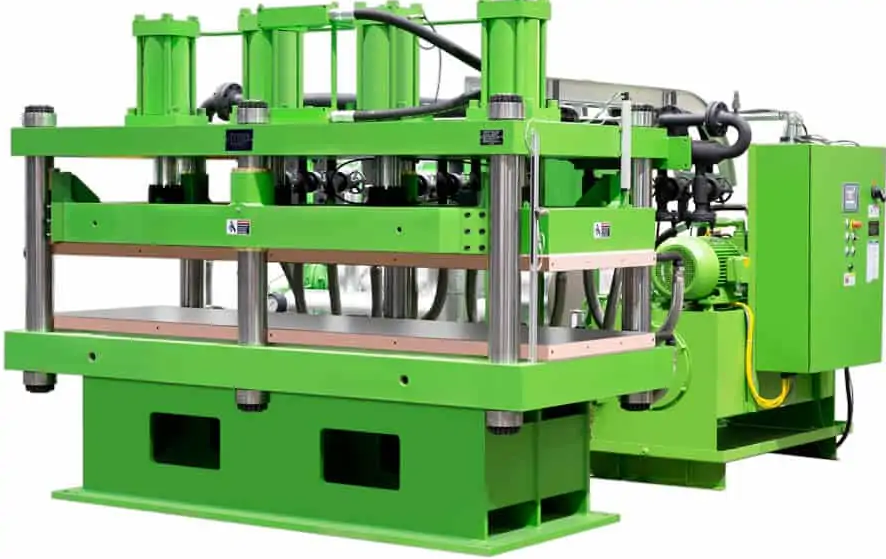

An automated hydraulic press is a type of press that uses a hydraulic cylinder to generate a compressive force. The hydraulic cylinder is controlled by a computer, which allows the press to be operated with great precision. Automated hydraulic presses are used in a variety of industries, such as automotive, aerospace, and electronics.

One of the key advantages of an automated hydraulic press is its ability to apply very high forces with great accuracy. This makes it ideal for applications where precise force is required, such as in the stamping of car parts or the assembly of electronic components.

Another advantage of automated hydraulic presses is their safety. Unlike mechanical presses, which can be dangerous if they malfunction, hydraulic presses are much safer to operate. This makes them ideal for use in environments where safety is a concern, such as factories or warehouses.

If you’re looking for a press that can offer high precision and safety, an automated hydraulic press might be the right choice for you.

The Different Types of Automated Hydraulic Presses

There are many different types of automated hydraulic presses, each with its own advantages and disadvantages. The most common types are:

1. Single-acting hydraulic presses: These presses have a single ram that moves up and down in a simple linear motion. They are typically used for lighter tasks such as stamping or pressing small parts.

2. Double-acting hydraulic presses: These presses have two rams that move in opposite directions, providing more power than single-acting presses. They can be used for heavier tasks such as forging or press-fitting larger parts.

3. C-frame hydraulic presses: These presses have a “C” shaped frame with the ram mounted on one side. They offer more stability than other types of presses and are typically used for heavy-duty tasks such as forging or extruding metal.

4. Four-post hydraulic presses: These presses have four posts that support the weight of the ram and provide greater stability during operation. They are often used for large-scale stamping or pressing operations.

Pros and Cons of an Automated Hydraulic Press

When it comes to automated hydraulic presses, there are both pros and cons that need to be considered. Here are some of the key points to keep in mind:

Pros:

* Can significantly increase productivity and efficiency

* Can help to improve product quality

* Greater consistency and repeatability

* Reduced operator fatigue

Cons:

* Requires a significant initial investment

* Needs to be properly maintained

* Can be complex to operate

What Materials can be Pressed with an Automated Hydraulic Press?

There are a variety of materials that can be pressed with an automated hydraulic press. These include metals, plastics, composites, and even some organic materials. The key is to choose the right die and setup for the material being pressed.

Some materials, such as metals, require a die with sharp edges to create a clean cut. Others, like plastics, may require a die with smooth sides to avoid crushing the material. The type of material also dictates the amount of pressure that can be applied. Softer materials can withstand more pressure than harder ones.

The best way to determine what material can be pressed with an automated hydraulic press is to consult with a manufacturer or supplier. They will have experience working with different materials and can offer guidance on the best way to press each one.

How to Operate an Automated Hydraulic Press

Operating an automated hydraulic press is a relatively simple process, but there are a few things you should keep in mind to ensure smooth operation.

Firstly, make sure that the power supply to the machine is turned on and that the oil level in the reservoir is sufficient. Once these two things are checked, you can start the press by pressing the green “start” button on the control panel.

The next thing to do is to load your material onto the bed of the press. Once your material is in place, you can lower the ram of the press by pressing the down arrow on the control panel. The speed of descent can be controlled by how long you hold down the arrow – if you want a slower descent, simply hold the button down for longer.

Once the ram has reached its lowest point, it’s time to start pressing! The amount of pressure exerted by the machine can be controlled using the pressure gauge on the control panel. Simply turn it clockwise to increase pressure or counter-clockwise to decrease pressure.

When you’re finished pressing, simply raise the ram back up to its original position by pressing the up arrow on the control panel. And that’s it – you’ve now mastered operating an automated hydraulic press!

Alternatives to the Automated Hydraulic Press

If you’re looking for alternatives to the automated hydraulic press, there are a few options available. One option is the pneumatic press, which uses air pressure to exert force on the workpiece. Another option is the electromechanical press, which uses a combination of electrical and mechanical forces to exert pressure on the workpiece.

Conclusion

If you want to learn how to use an automated hydraulic press, then this article is for you. We have provided a step-by-step guide on how to operate this type of press, as well as some tips and tricks on how to get the most out of it. We hope that after reading this article, you will feel confident in using an automated hydraulic press and be able to accomplish all of your pressing needs.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us