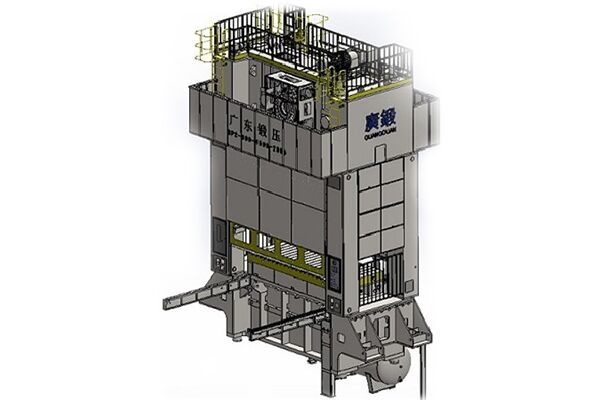

OEM Stamping Press Solutions: Inside Guangduan’s High-Tech Breakthroughs

The global push for manufacturing efficiency has made OEM stamping press solutions a critical cornerstone of today’s production strategies. From automotive body panels to home appliance shells and precision electronic components, manufacturers require stamping systems that offer high accuracy, fast cycle times, and uncompromising reliability.

In this article, we take a closer look at Guangduan’s advanced technology platform – highlighting how our latest Stamping Presses are reshaping the metal forming landscape. You’ll discover why industry leaders are choosing our solutions to power smart factories and secure long-term performance in an increasingly competitive market.

Why OEM Stamping Press Solutions Matter in 2025

Demand for lightweight components is soaring, yet materials are harder and thinner than ever. That means:

• higher press tonnage

• finer stroke control

• smarter line integration

OEMs can no longer treat the stamping shop as an isolated island. Data flows from Enterprise Resource Planning (ERP) to the press and back again. Predictive maintenance, digital twins, and closed-loop quality feedback are now baseline requirements. Guangduan addresses these needs through a blend of mechanical strength and digital intelligence, packaged in equipment built to outlast product life cycles.

Meet Guangduan

We started stamping solutions in Shunde more than six decades ago. Today our campus hosts:

• over 100 engineers, including 13 with senior titles

• nearly 100 CNC machining centres for in-house part production

• a calibration lab with 1 000+ advanced instruments

By welding our own machine bodies and grinding our own crankshafts we control every micron of accuracy. We speak from the shop floor, not a sales desk – every spec you read is backed by steel, cast iron, and continuous tests under real loads.

What Is a Stamping Press?

A Stamping Press is a precision tool that cuts or forms sheet metal using dies and a powerful crankshaft-driven mechanism. It’s an essential part of any high-volume production line.

At Guangduan, our STPP Series mechanical stamping press features:

✅ A welded steel body for maximum rigidity

✅ Double crankshafts designed in reverse for balance

✅ Eight-sided guide rails that enhance accuracy and reduce lateral force

✅ Hydraulic overload protection that responds quickly and reliably

✅ High-torque wet clutch that ensures low noise and minimal wear

These features make it ideal for industries such as automotive, appliance manufacturing, and metal forming.

Innovation Through Engineering and Analysis

At Guangduan, we believe that outstanding machines begin with smart, precise engineering. That’s why we rely on SOLIDWORKS 3D software and modular design principles throughout our product development process. Every press we produce is engineered with purpose – to deliver long-term performance, high accuracy, and maximum efficiency in demanding production environments.

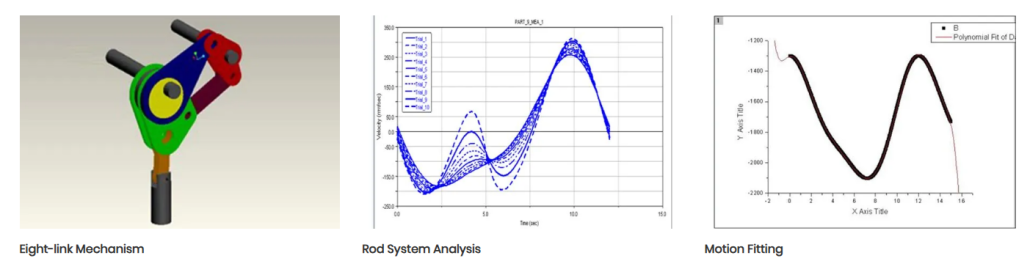

Advanced Motion and Structure Optimization

We invest heavily in digital simulation and analysis to ensure every press in our lineup meets the highest standards:

✅ Finite Element Analysis (FEA)

Using ANSYS software, we conduct structural analysis on critical welded components. This allows us to identify and reinforce stress points, ensuring that our machines maintain structural rigidity and precision even after years of continuous operation.

✅ Multi-Link Rod System Analysis

In partnership with leading engineering universities such as South China University of Technology, we analyze and optimize rod systems for improved motion dynamics. This leads to smoother operation and enhanced press efficiency.

✅ Eight-Link Mechanism Design

Our eight-link drive design ensures stable movement, reduces component wear, and improves stamping precision. This contributes to both longer machine life and better part quality.

Through these innovations, Guangduan delivers OEM stamping press solutions that seamlessly combine structural strength with high-speed, high-precision motion – making them ideal for modern automated production lines.

Intelligent Automation

Speed and efficiency are essential in today’s fast-paced manufacturing landscape. To meet these demands, Guangduan’s large presses feature one-touch quick die change technology, dramatically cutting setup time. The entire die change process can be completed in under 3 minutes.

Key Benefits

✅ Significantly reduced machine downtime – Keep production flowing with rapid tool changes

✅ Improved worker safety – Minimize manual intervention with automated clamping and positioning

✅ Smart factory integration – Easily interface with automated scheduling and production control systems

In addition, we offer fully integrated uncoiling, leveling, and feeding systems, allowing customers to build complete, automated stamping lines that deliver consistent output with minimal human intervention. By focusing on intelligent automation, Guangduan helps manufacturers reduce cycle times, lower costs, and stay competitive in an increasingly digital industrial landscape.

OEM Integration and PLC Control

At Guangduan, we recognize that every manufacturing facility has unique requirements. That’s why our OEM stamping press solutions are designed for maximum flexibility and intelligent automation. Whether you’re operating a single press or managing a full production line, our systems adapt to your workflow.

Each press in our lineup can be equipped with advanced control features, including:

✅ Mitsubishi FX-3GA PLC for reliable, high-speed logic control

✅ Human-Machine Interface (HMI) with a user-friendly touchscreen for real-time monitoring and adjustments

✅ MES System Integration, allowing seamless data exchange with your plant’s management systems

These features enable real-time communication between the press and your central control hub, improving operational transparency and synchronization. With PLC-based control and MES connectivity, you can automate production scheduling, track machine performance, and respond quickly to production changes – all from a single interface.

This level of integration supports smart manufacturing goals, reduces downtime, and enhances both efficiency and product quality. Whether you’re upgrading an existing line or building a new one, Guangduan offers the digital tools you need to stay competitive in a fast-moving industry.

Why Choose Guangduan‘s OEM Stamping Press Solutions?

As a trusted partner in OEM stamping press solutions, we offer more than just machines – we deliver value, customization, and long-term support.

- Key advantages:

• Tailor-made press systems based on customer requirements

• Integration with automated lines and MES platforms

• Short lead times and fast service response

• Ongoing R&D partnerships with leading universities

• In-house design, testing, and validation processes

Closing Thoughts

The future of manufacturing is automated, intelligent, and efficient. Guangduan is helping shape that future through our continued investment in R&D, smart technology, and customer-focused innovation. Whether you’re a Tier 1 automotive supplier or a metal processing plant, our OEM stamping press solutions are designed to meet your goals with precision and reliability.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us