How a Precision Hydraulic Stamping for AI Servers Enhances Cooling

Precision Hydraulic Stamping shapes brackets, ducts, and frames with tight, repeatable tolerances for AI Servers. Smooth edges guide air. Clean fits improve contact at thermal interfaces. Less turbulence means fans work less and run quieter. That is the “what.” The real intrigue is the “how.” How do press accuracy, lubrication, and servo control turn metal into cooler airflow? And which tiny features deliver the biggest thermal gains? Keep reading – we’ll map the steps and reveal the hidden wins.

Why Heat Becomes A Business Problem

AI servers compress accelerators, powerful CPUs, and dense memory into tight spaces. That density pays dividends in performance – but it also concentrates heat. The usual culprits are small, ordinary defects: a bracket a hair out of plane, an edge that creates turbulence, or a mounting hole that shifts a duct by a millimeter. Each one adds resistance to airflow. Together, they raise fan duty cycles, bump energy costs, and risk throttling during peak loads. Over a fleet of racks, that becomes a budget line item you can’t ignore.

This is where Precision Hydraulic Stamping for AI Servers earns its keep. When every bend, flange, and louver follows your drawing with repeatable accuracy, airflow stays laminar longer, pressure drops fall, and hot spots shrink. Cooling stops being a firefight and starts behaving like a predictable, engineered system.

How Precision Hydraulic Stamping Improves Cooling

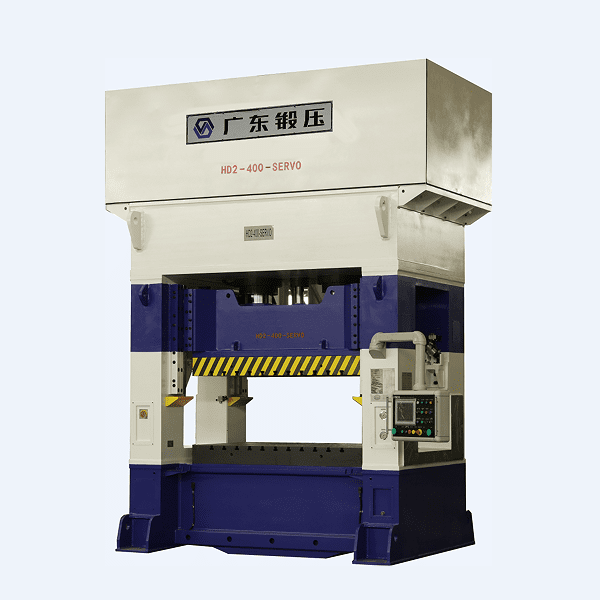

Our presses are built on a welded steel box frame for rigidity. That stiffness matters: a stable machine makes stable parts. The slide runs on an eight-sided full-guide rail, so the motion remains true and angular error stays low. In practical terms, you get consistent geometry across long runs – exactly the behavior cooling systems rely on.

- Smooth Paths, Lower Turbulence

Air hates sudden change. Sharp transitions, burrs, or offset holes create swirl and recirculation. Guangduan’s process tightens tolerances and refines surface quality, which keeps airflow attached to the parts you specify: baffles, fan trays, cold-plate brackets, and card guides. With cleaner edges and uniform offsets, the same fans move more air through the heat sources that need it most.

- Stable Precision Over Time

Cooling performance must last years, not just pass a lab test. To hold tolerances over long campaigns, we run a thin-oil continuous circulation lubrication system that minimizes wear on slides and guides. A servo closed-loop control architecture – combining a servo drive with pressure and displacement sensors plus PLC logic – tracks each stroke in real time. The result is high precision with low noise and low vibration, which protects delicate fins and soldered joints while preserving the geometry that controls airflow.

- Cleaner Interfaces, Better Heat Transfer

Thermal efficiency depends on contact quality. Micro-burrs, contamination, and uneven surfaces reduce the effectiveness of pads, pastes, and cold plates. Our controlled motion and lubrication reduce residues and limit surface defects, leading to tighter fits and cleaner interfaces. That translates into lower contact resistance and more consistent temperatures across the board.

What Makes Guangduan Different

We don’t just ship machines; we build a repeatable path from your thermal intent to parts on the floor. Precision Hydraulic Stamping for AI Servers at Guangduan combines mechanical stiffness, sensing, and operator-friendly control so your airflow design becomes a reliable production reality.

- Intelligent Control You Can Actually Use

Process tuning is fast and transparent. Operators adjust parameters on a touch-screen with grating-ruler feedback and immediate confirmation. Need to pivot from a duct louver to a chassis bracket? Store up to 20 sets of process parameters and swap without losing your “golden” settings. This reduces changeover time and preserves the airflow geometry you validated in R&D – shift after shift, batch after batch.

- Built-In Safety, Built-In Uptime

Cooling goals go nowhere if your line stops. A slider locking device can secure the ram at any position to protect teams during setup or maintenance. Lower-limit switches and two-hand anti-repeat controls add redundancy on the shop floor. Multi-level protections – like parameter anti-error checks in the HMI – reduce operator mistakes and unplanned downtime. More runtime equals more parts that meet your thermal spec, delivered when you need them.

- Designed For Real-World Manufacturing

Data-center teams don’t want exotic processes that are hard to scale. Guangduan focuses on manufacturability: robust frames that travel well, low-vibration operation that preserves die life, and servo logic that keeps quality on target without endless manual tweaking. Because the machines themselves are quiet and stable, on-line inspection becomes easier, and SPC data trends stay predictable. That’s how you hold the cooling line across thousands of units.

- Turning Thermal Theory Into Measurable Wins

If you’re fighting hot spots or chasing acoustic targets, the fastest gains often come from stamped geometry. With Precision Hydraulic Stamping for AI Servers, you can:

- Trim pressure drop by smoothing transitions and eliminating air leaks around shrouds and panels.

- Protect fins and solder joints through low-vibration press cycles and clean edges.

- Improve thermal interface performance by delivering flatter, cleaner mating surfaces.

- Keep airflow paths consistent with tight, repeatable tolerances that survive long production runs.

You’ll notice it in the metrics that matter: fan speeds drop, energy consumption stabilizes, and turbo frequencies hold longer under heavy inference or training loads. Reliability improves because components run cooler, and the data hall sounds less like a wind tunnel.

- From First Article To Full Scale

Guangduan supports you from design to mass production. We begin with DFM conversations focused on airflow and thermal interfaces. Pilot runs confirm pressure-drop targets, fan curves, and acoustics. On the line, we monitor critical dimensions – the ones that actually affect cooling, not just easy-to-measure features – so your racks behave the same in month twelve as they did on day one.

Closing Words

Ready to cool more with less? Talk to Guangduan about Precision Hydraulic Stamping for AI Servers. We’ll review your airflow path, identify high-leverage stamped features, and propose a build plan that keeps temperatures – and costs – under control. Our team can turn your thermal model into stamped parts that perform in the lab and on the floor.

Cooling has become a first-order constraint for AI infrastructure. The smart move isn’t adding bigger fans; it’s reducing the work those fans have to do. By aligning design intent with manufacturing reality, Precision Hydraulic Stamping for AI Servers gives you quieter systems, steadier temperatures, and more performance headroom – today, and through years of continuous operation. With Guangduan, thermal discipline isn’t fragile or theoretical. It’s baked into every stroke, every part, and every rack you deploy.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us