Split-Body Press Machine for Auto Parts Simplifies Installation

Press machine for auto parts technology is evolving fast, yet one customer concern remains constant: how to move, install, and commission heavy equipment without slowing production. At GUANGDUAN, we respond with a split-body architecture that pares down logistical headaches and accelerates ramp-up, while keeping the uncompromising rigidity our automotive partners demand. Below, we explain why the split-body press machine for auto parts matters, what engineering choices make the GD2 series unique, and how the design translates into measurable value on the shop floor.

Reimagining Heavy Press Transport

Moving a 600-ton-plus press across continents and through narrow plant aisles can feel like a project in itself. Traditional monolithic frames require specialized trailers, heavy cranes, and days of alignment work. The GUANGDUAN solution replaces that complexity with a two-piece main frame locked together by a pre-tight pull-lever system.

✅ Less crane capacity needed – Each split segment falls within standard rigging limits, so plant infrastructure stays untouched.

✅ Faster doorway clearance – Modules slip through existing access points that a single-block frame would never fit.

✅ Precision preserved – The pull-lever pre-tight structure clamps the halves with uniform stress, preserving geometric accuracy better than field welding.

✅ Reduced installation hours – Alignment pins and pre-machined contact faces let technicians square the frame in one shift, rather than several.

Beyond transport, the split-body concept also future-proofs plant layout. Should you rearrange material flow or add a second line, each press segment can be repositioned with common forklifts – an agility impossible with a single-block behemoth.

Engineering Strengths That Set GUANGDUAN GD2 Apart

• Welded, High-Rigidity Steel Frame

Our machine body and slide are fabricated from superior-quality steel plates, stress-relieved after welding. Finite-element analysis guided us to reinforce high-load zones without adding unnecessary mass, so the press machine for auto parts retains stiffness even under eccentric progressive dies.

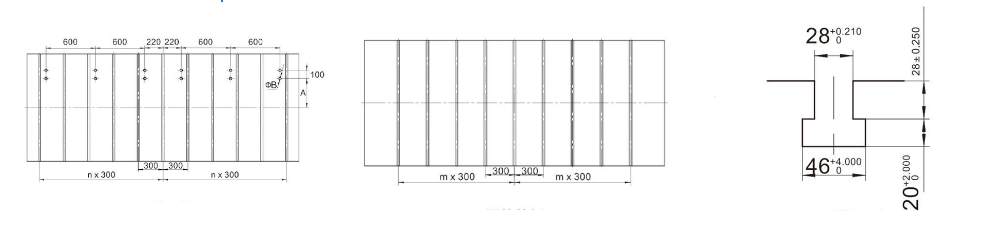

• Eight-Surface Full-Guideway Slide

Where many presses rely on four-point gibbing, we machine eight long guide surfaces into both slide and columns. The result is:

✅ Lower side force – critical when large transfer bars extend tooling width.

✅ Stable accuracy – minimal yaw or pitch across the stroke, helping dies last longer.

✅ Superior unbalanced load resistance – perfect for multi-station and progressive operations.

• High-Torque Wet-Type Clutch & Two-Level Gear Train

A multi-plate, oil-immersed clutch delivers swift starts and stops with little wear or noise. Mated to a two-level gear set plus intermediate idler, it widens crank spacing, keeps overall press height low, and boosts eccentric-load capacity. Operators gain:

✅ Smooth inching for die setup

✅ Continuous strokes up to 35 SPM (model-dependent)

✅ Low acoustic footprint that meets modern plant standards

Of course, no press stands alone. The GD2 ships with two- and three-dimensional servo interfaces for robots, coil feeders, or transfer rails, making the jump to fully automated stamping lines straightforward.

Tangible Gains for Your Production Line

A capital purchase must pay back quickly. GUANGDUAN’s split-body presses shorten the timeline on three fronts:

• Installation cost – Fewer rigging hours and lighter cranes trim thousands from start-up budgets.

• Die longevity – Eight-surface guidance holds alignment, so tooling wear slows and maintenance windows open wider.

• Throughput flexibility – High stroke rates coupled with quick-change cushions mean the same press tackles door-panel draw work Monday and EV battery shields Tuesday.

Consider also the environmental dimension: wet-type clutches prevent clutch-dust emissions, and compact frames free floor area for energy-efficient material flow. Sustainability targets become easier to hit without extra capital.

Case in point: A Tier-1 supplier replaced a 450-ton fixed-frame press with a 600-ton GD2. Despite 33 % higher tonnage, forklift lanes widened because the overall height dropped by 400 mm, and installation finished 40 % quicker. Output rose 18 % in the first quarter, largely through faster die changeovers enabled by the split-body‘s easy access panels.

• Key Takeaways for Plant Managers

✅ Rapid ROI – Lower install costs, higher uptime

✅ Scalable automation – Servo-ready ports on every frame

✅ Operator safety – Stable gibbing plus low-noise clutch reduce fatigue

✅ Future mobility – Re-locate or resell with less disassembly risk

Ready to Upgrade?

At GUANGDUAN we do more than supply machines – we partner from concept to commissioning, delivering press machine for auto parts solutions that let you stamp smarter, ship sooner, and grow faster. Talk with our application team today to see how a split-body GD2 press can flex to your exact die set, floor plan, and production target.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us