GUANGDUAN’s Role Among Trusted Press Machine Suppliers in Algeria

Press machine suppliers in Algeria are playing a decisive part in the country’s industrial upgrade, and at GUANGDUAN we are proud to be at the center of that transition. Founded in 1958, we have grown from a regional workshop into South China’s largest forging-and-pressing equipment manufacturer. Today we bring more than six decades of R&D knowledge, ISO-9001-certified production, and rapid after-sales support to Algerian factories that are scaling up for automotive, white-goods, and infrastructure projects.

Algeria‘s Growing Need for Advanced Forging Solutions

Algeria’s economy is diversifying fast. Government incentives for local content, a young workforce, and proximity to European markets are driving demand for heavier, more precise metal-forming lines. Yet local firms still depend on reliable press machine suppliers in Algeria who can offer full-lifecycle support instead of “ship-and-forget” deliveries. Algerian buyers tell us they face three main hurdles: inconsistent machine accuracy, rising energy costs, and the need for flexible lines that can switch from small batches to mass production. Because imported machines often come without dedicated service teams, downtime can drag on for weeks. That is why sourcing presses from partners who combine proven engineering with local technical response is crucial. To meet this gap, we have established cooperative service stations in Algeria, staffed by GUANGDUAN-trained engineers. Their mission is simple: keep customer uptime throughout the year.

• Key Market Drivers

•Steady 6 % annual growth in automotive component exports

•Government tax breaks for factories that localize ≥40 % of value-added processes

•Rapid expansion of household-appliance assembly lines needing deep-drawing presses

The result? An urgent, sustained demand for trustworthy press machine suppliers in Algeria – a role we are uniquely equipped to fulfill.

GUANGDUAN – Delivering Reliability and Innovation

• Advanced Engineering

The flagship GY2S series embodies everything Algerian plants demand from modern press machine suppliers in Algeria: rigidity, precision, and operator-friendly controls. The welded-steel box frame resists deflection even under full-tonnage blanking. An eight-sided full-length guideway keeps the slide parallel throughout its travel, protecting dies from uneven wear. Continuous thin-oil lubrication, delivered through micro-metered injectors, eliminates the “dry-start” conditions that shorten bushing life in conventional systems.

• Servo Closed-Loop Intelligence

A PLC-driven servo pack coordinates motor, pressure, and displacement sensors in a 1 kHz feedback loop. This architecture:

✅Cuts approach speed to 50 mm/s when the die closes, then ramps up forming speed – boosting cycle times without hammering tooling.

✅Holds tonnage within ±1 % of set value, guaranteeing uniform grain flow in hot-forged blanks.

✅Records force-displacement curves for every stroke, allowing QA teams to flag drift before it causes scrap.

Twenty mold recipes can be stored and recalled from the 10-inch touchscreen, and safety interlocks – two-hand control, slide-lock at any position, lower-limit switches – comply with CE and NR12 standards.

• Built for Energy Savings

Because the servo pump idles when no force is required, the GY2S often draws less than half the power of a fixed-speed hydraulic press in the same tonnage class. Plants that switch from legacy machines typically see payback in 12–18 months, a figure that resonates with Algerian CFOs balancing capital expenditure against rising electricity tariffs.

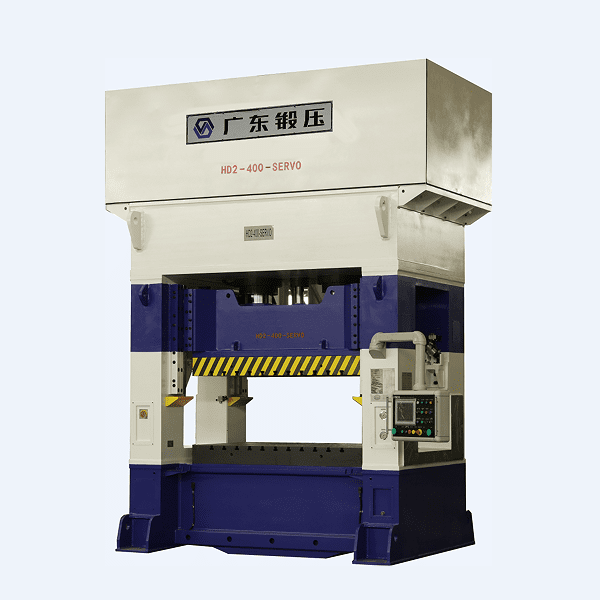

(GUANGDUAN Hydraulic Press GY2S Series)

Building Sustainable Success with Algerian Manufacturers

Close collaboration, rather than one-off machine sales, is at the heart of our approach to the Algerian market.

First, we map each customer’s value stream to identify bottlenecks – be it in blanking, progressive stamping, or final assembly. Next, we configure press tonnage, shut-height, and automation modules (robot loaders, coil feeders, die-change carts) around existing floor plans, keeping civil-works costs low. Finally, we train local technicians to perform preventive maintenance using the same laser trackers and vibration sensors found in our Shunde headquarters.

• Partnership Benefits at a Glance

Quick turn-around service-Mobile teams based in Annaba and Blida carry genuine spare parts, ensuring restart.

Knowledge transfer-Annual workshops on die design and servo-parameter optimization raise local engineering capability.

Long-term cost control-Energy audits before and after installation quantify savings, helping plants secure green-loan incentives.

Scalable technology-Modular drives and valve blocks let customers upgrade tonnage or add IoT dashboards without replacing the entire press.

Longer term, GUANGDUAN will deepen R&D cooperation with Algerian universities, exploring lightweight-alloy forming and predictive maintenance algorithms that cut unplanned downtime to near-zero. Our vision is simple: to stand not only as reliable press machine suppliers in Algeria, but as co-innovators who drive the region’s transition from raw-material exporter to high-value manufacturer.

The Road Ahead

We believe the next growth cycle in Algeria will be defined by safe, efficient, and data-rich production lines. By pairing our six-decade heritage with local insight, GUANGDUAN is prepared to deliver the presses, the know-how, and the after-sales support that make that vision real – stroke after stroke, shift after shift. If your plant is planning its next capacity upgrade, reach out to our North Africa team for a no-obligation energy audit and ROI projection. Together, we can forge a stronger, smarter manufacturing landscape across Algeria.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us