Why Heavy Duty Mechanical Press Machine Is Worth the Investment

Why heavy duty mechanical press machine is worth the investment? Because it delivers power, speed, and repeatable accuracy. It turns tough metals into precise parts. We build presses for the way production actually runs – under shifting loads, tight takt times, and pressure to hold tolerance over long campaigns. Our GD2 Straight Side Double Point Multi Station Press is engineered around those realities, turning persistent shop-floor pain points into predictable performance.

What Makes The GD2 Different

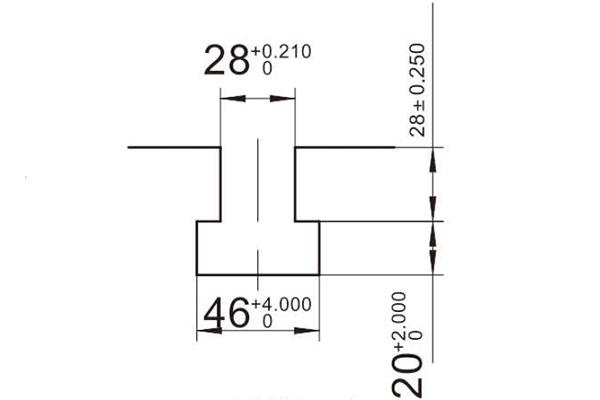

The GD2 begins with a structure you can trust. The machine body and slide are welded from superior-quality steel plates, creating a rigid frame that resists deflection under heavy forming forces. For capacities at or above 600 tons, we use a split machine body with a pull-lever pre-tight arrangement. This configuration simplifies transport and installation, yet locks down as a unified structure once commissioned. The benefit is simple: faster setup, less disruption, and a frame that stays true when the real work starts.

Frame And Guidance Built For Precision

Off-center stamping loads are a fact of life in progressive and multi-station tooling. To counter them, the GD2 increases the interval between the crank and connecting rod. That seemingly small change adds meaningful resistance to unbalanced loading and helps the press retain precision over time. We pair that with an eight-surface long-guideway slide. The extended guiding length keeps side forces low and motion straight, so the slide tracks cleanly even when dies are stamping asymmetrically. For teams chasing stable Cp/Cpk, this guidance system becomes a quiet ally shift after shift.

Transmission Optimized For Multi-Station Work

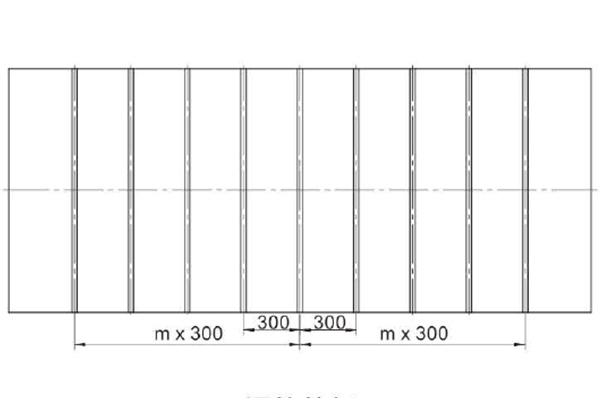

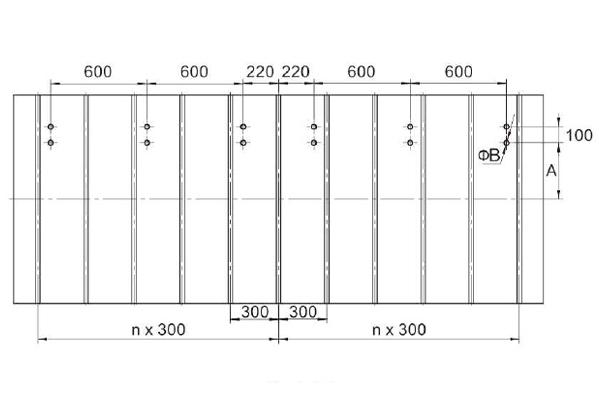

The press uses a two-level gear transmission to support high operating strokes per minute without sacrificing control. For multi-station and progressive die applications, we add an idler mechanism between pressure points. This widens the load-bearing interval, boosts capacity against eccentric loads, and allows a lower overall machine height. In practice, you gain a compact, well-balanced drive with a wide worktable surface – a helpful combination when floor space is tight but throughput targets are aggressive. This layout is tailor-made for multi-station dies that need room to breathe.

Wet-Type Clutch: Sensitive, Durable, And Clean

The GD2’s high-torque wet-type clutch uses oil-filled friction plates. The multi-plate, low-inertia design connects smoothly, starts and stops sensitively, and tolerates frequent interruptions during continuous line operation. Because the system runs cleanly and quietly, it supports environmental requirements and improves the operator experience. If your line relies on a wet-type clutch mechanical press, this approach gives you long service life without the performance drift that eats into cycle time or part quality.

Die Cushions Designed For Progressive And Multi-Station Stamping

Upper and lower die cushions are purpose-built for multi-station workflows. They deliver high force in a compact volume, respond quickly, and hold pressure with minimal fluctuation. Each cushion’s pressure is independently adjustable, so your team can fine-tune forming windows for different step distances, materials, and features. The slide can also be fitted with a multi-section air cushion and an upper knockout cylinder to simplify part release and protect delicate geometries. For a long-tail keyword match, think of the GD2 as a progressive die stamping press that adapts to real tooling demands.

The Payoff On The Shop Floor

A Heavy duty mechanical press machine must do more than look good on a spec sheet; it has to remove daily friction. The GD2 focuses on the moments that make or break OEE: alignment under load, stroke stability at speed, and predictable setup.

- Precision That Holds: Eight-surface full-guideway guidance and stronger resistance to unbalanced loads keep parts in tolerance over long runs, reducing rework and scrap.

- Throughput With Control: The two-level gear train supports high stroke rates while maintaining stable slide motion, so you scale output without inviting chatter or drift.

- Compact, Capable Footprint: Lower overall height and a wide table surface balance space savings with die flexibility – ideal when expanding a cell within an existing line.

- Faster Commissioning: The split body with pull-lever pre-tight structure (≥600 t) streamlines transport and installation, shortening the path from delivery to first good part.

- Operator-Friendly Dynamics: The wet-type clutch’s low noise and clean operation support a better environment and smooth stop-start behavior during short interruptions.

- Process Control At The Tool: Independently adjustable die-cushion pressures let engineers dial in each stage, stabilizing forming pressures and improving first-pass yield.

For automation-driven lines, the GD2 includes 2D and 3D servo production line interfaces. That means feeders, transfers, and downstream equipment can sync without awkward workarounds. Stable guidance reduces side force on punches and dies, which can extend tooling life and smooth maintenance intervals. Over time, these incremental gains add up: fewer unplanned stoppages, more consistent cycle times, and less energy wasted chasing alignment after an off-center hit.

Consider the practical ROI arc. When a press resists eccentric load and holds precision, you preserve die geometry and reduce scrap. When the clutch engages smoothly, you avoid micro-stoppages that kneecap throughput. When transmission geometry is tuned for multi-station stamping, you get capacity in a smaller vertical envelope, freeing space for material flow. Each element compounds, creating the kind of predictable performance that finance teams describe as “boringly profitable.”

How To Specify Your GD2

Before specifying, map your real constraints. Start with die layouts, expected eccentric loads, and target stroke rates. Define step distances, cushion force requirements, and the need for upper knockout or multi-section air cushions. From there, size the frame and select capacity tiers, especially if you’re approaching or exceeding 600 tons, where the split-body structure shines during installation.

At Guangduan, we align transmission, guidance, and clutch behavior with your takt time and part quality targets – not the other way around. For lines focused on progressive or multi-station stamping, we recommend pairing the GD2 with servo-synchronized feeding and transfer. This reduces hand-off errors, stabilizes part presentation, and leverages the press’s low-side-force slide motion. If your goal is to standardize across multiple cells, the GD2’s compact height helps drop a higher-capacity press into an existing hall without reworking every utility.

A Final Thought on Total Cost

the best Heavy duty mechanical press machine protects your most expensive assets – your dies, your schedule, and your team’s time. Precision that lasts trims the cost of poor quality. Clean, low-noise operation reduces fatigue and supports compliance. And a drive train tuned for multi-station work eliminates the hidden tax of constant micro-adjustments.

Call To Action: Ready to validate the fit? Contact Guangduan for a quick engineering review of your tooling, stroke needs, and automation plan. We’ll propose a GD2 configuration – capacity, table dimensions, cushions, and interfaces – that matches your throughput and quality goals. If you’re building a progressive die stamping cell or expanding a multi-station line, we’ll help you turn today’s constraints into tomorrow’s capacity with a press that earns its keep from day one.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us