Why Your Metal Stamping Machine Needs a High-Stability Welded Frame

In stamping, tiny movements become big problems. A high-stability welded frame is a rigid body made from steel plates, welded and heat-treated to remove stress. It holds the slide, guides, and drive in precise alignment. It cuts vibration. It protects your dies. It keeps parts consistent across long runs. It also supports faster changeovers and safer setups. Sounds simple. Yet many presses still flex under load and drift out of spec. What happens on your floor when the frame isn’t stable? The answer may surprise you in the next section.

The Real Cost Of Flex And Vibration

When a press frame flexes, the slide does not return to the exact same position every stroke. That tiny drift becomes scrap, tool wear, and rework. You also lose speed because operators slow the press to keep parts within tolerance. In short, vibration steals money – quietly, every shift.

At Guangduan, we build the body of each Metal Stamping Machine by welding high-strength steel plates, then performing high-temperature annealing. This releases internal stress, increases rigidity, and stabilizes long-term precision. A stiff, stress-relieved frame resists thermal growth and off-center loads, so your parts stay in spec from the first stroke to the ten-millionth.

❓ Why Welded And Annealed Beats “Good Enough”?

A high-stability welded frame acts like a solid foundation for a house. Everything you mount on it – guides, gibs, drive shafts, gears – runs truer and lasts longer. You feel it in smoother motion, hear it in lower noise, and see it in repeatable parts. With less deflection, the slide follows a consistent path, which protects delicate dies during forming and deep drawing.

• Less deflection under peak load

• Lower vibration for tighter repeatability

• Longer die life and fewer emergency stops

• Higher speed without quality compromise

We also consider changeover time. A rigid frame supports our die clamping system and automatic work table (self-moving), so dies seat and release cleanly. That means quicker changeovers, fewer shims, and less risk of misalignment after maintenance. When every minute of downtime hurts, this is a practical win.

What A High-Stability Frame Enables Inside The Press

A strong frame is the backbone; the rest of the machine must be just as disciplined. Our two-point/four-point single-acting precision mechanical presses are engineered as a complete system that keeps precision stable during real-world production.

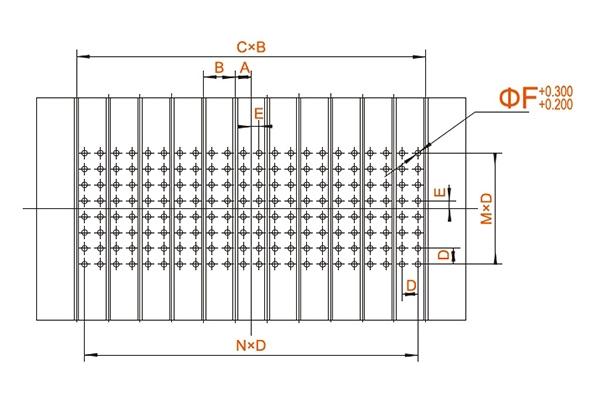

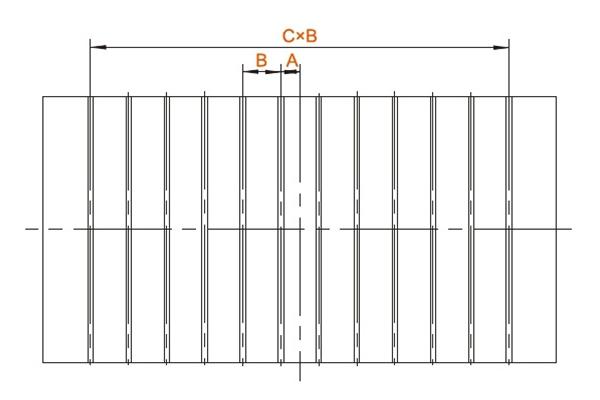

- Eight-Surface Long-Guideway Slide

The slide uses an eight-surface long-guideway design to lock alignment over the full stroke. This broad bearing area spreads the load, improving straightness and reducing wear. Your Metal Stamping Machine keeps its factory accuracy longer, with fewer adjustments between preventive services.

- PLC Control For Consistency

Electrics use PLC control to automate key settings: air pressure, die set height, and air cushion stroke. Instead of trial-and-error, operators call proven recipes. That cuts setup time and reduces human variation shift to shift.

• Automatic set-point control for repeatable forming windows

• Process safeguards for pressure and stroke limits

• Fewer manual tweaks, faster ramp-to-rate

- Five-Shaft Symmetric Transmission

The main transmission follows a five-shaft layout with symmetrically arranged gears. Opposing forces counteract each other, which steadies the slide under unbalanced loads and widens the left-right pressure interval for better off-center performance. Two-stage speed reduction blends herringbone gears at high speed and spur gears at low speed. Heat-treated alloy and forged steels, with controlled hardness differences, deliver strength and wear resistance without brittle failures.

You will notice:

• Better resistance to unbalanced loads on progressive or large single-hit dies

• Lower dynamic side forces on the connecting rods and guides

• Cleaner torque transfer for smooth acceleration and deceleration

A sealed drive with progressive thin-oil forced lubrication reduces wear and lowers noise. Pressure, flow, temperature, oil level, and drag are monitored so you can act before small issues become big ones.

The Precision Ecosystem By Guangduan

A great frame is necessary, not sufficient. Precision also depends on how the press handles blank holding, ejection, lubrication, and automation. Here is how your Metal Stamping Machine benefits from the rest of the Guangduan ecosystem.

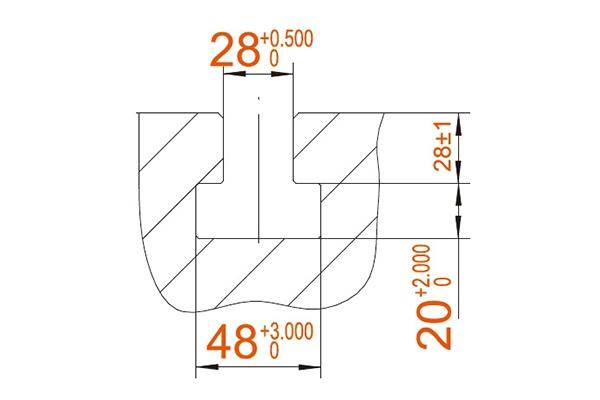

- High-Tonnage Pure-Gas Air Cushion

Our air cushion uses a single apical cap structure with dual main cylinders, stroke regulation, and optional lag-latching for special drawing. Hydraulic terminal buffering reduces impact and noise at the end of stroke. With progressive interval thin-oil lubrication, stability holds even under long, full-load runs. A single standard-length ejector rod covers different drawing depths, so you change hardware less often and keep the line moving.

- Faster Die Changes, Safer Setups

We integrate a die clamping system and an automatic work table to streamline changeovers. Dies seat squarely on a rigid base, so alignment checks are faster and first-off parts reach tolerance sooner. This reduces the real bottleneck in many shops: changeover, not cycle time.

• Quicker swaps with fewer alignment shims

• Reduced ergonomic risk for operators

• Higher overall equipment effectiveness (OEE)

Ready For Automated Stamping

Your press can be configured with automatic feeding and decoiling-leveling devices for end-to-end automated production. The rigid frame keeps feeds accurate and prevents harmonic chatter that can ripple down a coil line. As speeds climb, stability is the difference between smooth flow and constant micro-stoppages.

Bottom line: a high-stability welded and annealed frame is not a nice-to-have. It is the practical path to predictable quality, longer tool life, and faster changeovers on any Metal Stamping Machine. When precision must survive heat, speed, and off-center loads, the frame is where you win or lose.

Call To Action:

Ready to stabilize quality and shorten changeovers? Talk to Guangduan about our welded-frame, precision-guided, PLC-controlled Metal Stamping Machine solutions. We will review your parts, dies, and target cycle rates, then recommend a configuration that boosts uptime and cuts scrap – without over-engineering your investment.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us