Can a Precision Metal Forming Machine Solve Thin-Wall Distortion Issues

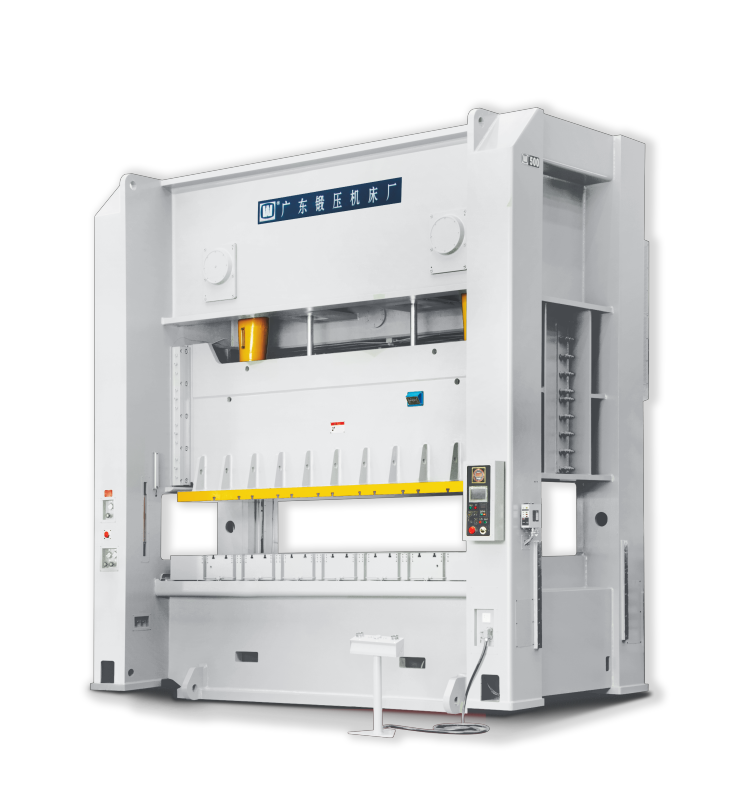

Thin-wall parts bend, warp, and spring back. A Precision Metal Forming Machine promises control. It is a high-rigidity press with stable slide guidance, smooth transmission, and adjustable cushions. It keeps the punch straight. It holds force evenly across stations. It runs fast without shaking your die. In short, it turns fragile walls into repeatable results. But can it truly stop distortion on your line? What happens when loads are eccentric, speeds climb, and tolerances tighten? The answer depends on how the press is built – and how you set it up. Ready to see where the limits are?

Why Thin-Wall Distortion Happens

Thin sections are sensitive to side force, eccentric load, and pressure fluctuation between stations. When the press frame twists or the slide tilts, the punch enters off-axis and the wall stretches unevenly. If strokes per minute climb without stable guidance, tiny errors become visible defects. Shops also struggle when different step distances and part features require varied cushion pressures; a single cushion setting rarely fits all.

At Guangduan, we approach distortion as a system issue. Rigidity keeps geometry true. Guidance keeps motion straight. Transmission keeps energy smooth. Cushions and knockout control the part, not the other way around. This is how a modern Precision Metal Forming Machine turns unstable thin-wall forming into repeatable production.

✅ Typical Pain Points On The Shop Floor

• Distortion or wrinkling on thin walls after high-speed runs

• Progressive dies suffering from unbalanced load and slide tilt

• Inconsistent part ejection causing micro-burrs and rework

• Cushion pressure “one size fits all” failing across stations

• Noise, heat, and wear that degrade accuracy over time

How Guangduan Attacks Distortion At The Source

Guangduan builds the core structure from welded, superior-quality steel plates for high rigidity. For capacities above 600 t, we use a split machine body with pre-tight pull-lever structure, making transport and installation easier while preserving stiffness once assembled. This matters because thin walls demand a press that does not “give” under eccentric load.

The two-level gear transmission provides smooth energy delivery and supports higher operating strokes of the slide, so you can increase throughput without losing control. We enlarge the interval between the crank and connecting rod to boost resistance to unbalanced loading – important when progressive dies concentrate forces off-center. The slide runs on eight-surface, long full-guideways. This minimizes side force and helps the press retain precision over time, even in continuous production.

✅ Key Design Choices That Matter

• Eight-Surface Slide Guidance: Low side force, high accuracy, strong retention – exactly what thin walls need for straight entry and clean forming.

• Unbalance-Load Resistance: Enlarged crank-rod interval and widened pressure spots help the press stay square under progressive and multi-station loads.

• Two-Level Gearing: Higher strokes per minute with stable motion, supporting thin-wall parts that prefer fast but controlled cycles.

• High-Torque Wet-Type Clutch: Oil-filled, multi-plate, low-inertia design. Starts and brakes sensitively, connects smoothly, supports frequent interrupt cycles, and runs with low noise.

• Multi-Section Die Cushions: Large force in a compact volume; fast reaction with small pressure fluctuation. Each cushion’s pressure can be adjusted independently to match different step distances and features.

• Automation-Ready Interfaces: Built-in two-dimensional and three-dimensional servo line interfaces make it simpler to integrate feeders, transfers, and robots for stable, hands-off thin-wall processing.

• Space-Saving Multi-Station Transmission Layout: Added idler mechanism increases the interval between pressure spots while lowering overall press height, yielding a compact footprint.

These elements do not operate in isolation. Together, they stabilize the tooling window so the die “sees” a straight, rigid, repeatable motion. That’s how a Precision Metal Forming Machine changes the thin-wall narrative from trial-and-error to dial-in-and-run.

What Results You Can Expect In Production

When rigidity, guidance, and pressure control align, thin-wall parts stop fighting the process. Operators report fewer timing adjustments between stations and more consistent part geometry from the first run of the day to the last. Progressive dies that previously drifted under side load now maintain entry alignment. With independent, multi-section cushions, you can tailor pressure by station so fragile flanges form cleanly while deeper draws receive stronger support. Ejection becomes predictable; surface marks and burrs decrease.

For planners, this means higher usable output per shift, simpler handoff to downstream assembly, and fewer emergency toolroom interventions. Maintenance teams see benefits as well: the wet-type clutch reduces wear and noise, while the rigid frame and full-guideways protect accuracy over long campaigns. And because the transmission supports higher strokes with smooth motion, you can scale speed responsibly – adding throughput without re-introducing distortion.

Not every thin-wall problem is identical. Material temper varies, step distances change, and part geometry evolves. That’s why Guangduan equips the press with adjustable cushions and knockout, a slide designed for side-force discipline, and structural features that resist eccentric loads intrinsic to multi-station work. The result is a Precision Metal Forming Machine that gives your die the stable platform it needs – today and as your product mix shifts.

Ready To See It On Your Parts?

- Book a quick application review with Guangduan’s team. Share your thin-wall drawings, target strokes per minute, and known pain points.

- We’ll map the forming sequence to guidance, transmission, and cushion control – then recommend settings and line integration steps.

- If you’re moving toward a more automated line, we can connect via the built-in servo interfaces and design for multi-station stability from day one.

Call to Action: Want to say goodbye to thin-wall distortion? Talk to Guangduan. Let’s pair your tooling with a Precision Metal Forming Machine architecture that holds accuracy, controls side force, and keeps output consistent – shift after shift.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us