What is a mechanical power press?

The definition of a Power Press Machine Is as Follows.

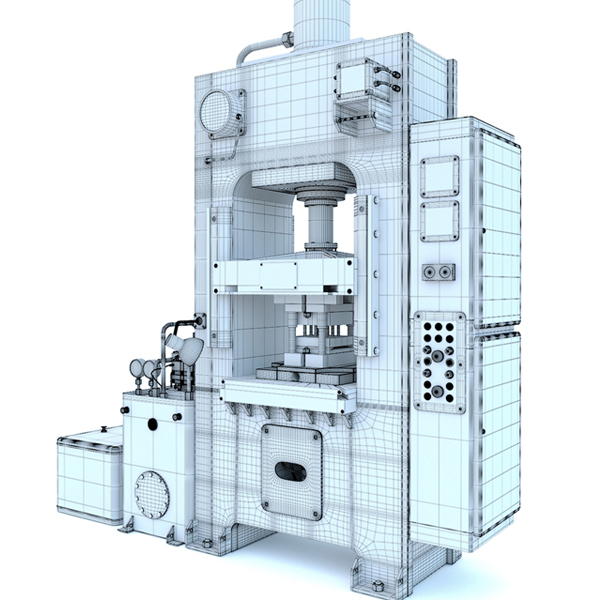

Let’s begin with the discussion on “What is a mechanical power press”. A machine that employs tremendous pressure to mold or cut materials, squeeze solids into thinner layers, or push liquids out of their containers is referred to as a mechanical press. Presses that use mechanical force can range in size from those that are controlled by hand to those that are so massive that they are used in factories and assembly lines. What Is a Mechanical Power Press?

A simple hand press can be used to remove a bearing from a machine assembly, while a gigantic press can be used to stamp sheet metal into the curved shapes used to produce automotive bodywork. Both presses can be used to extract a bearing from a mechanical assembly.

Industrial Mechanical Press

An industrial mechanical press is typically used to shear, bend, or form sheet metal in one of these three ways. A typical hydraulic ram has a lower, stationary base and a higher, vertically-moving ram that applies the force.

The part of the machine that applies force and slides along the axis is called the ram. The pressing ram can have a wide variety of mechanical configurations and frame designs in order to fit the many different pressing jobs.

Different Press Machines

There are many different methods by which the force that is used by a mechanical press might be generated. The force that is generated by a hydraulic press is caused by the movement of a cylinder piston. This piston is either pushed or pulled by fluid that is under very high pressure and is contained within one or more cylinders.

Pneumatic presses, which are functionally identical to hydraulic presses despite using pressurized air rather than fluid, are called pneumatic presses. To provide power to a mechanical press, an electric motor not only turns a crank but also engages a clutch and spins a huge flywheel at the same time.

In a servo-driven mechanical press, the force can be accurately controlled during the entirety of the ram stroke if, in place of the flywheel, high-precision motors are used in place of the flywheel.What Is a Mechanical Power Press?

Power Press Machines

A power press machine is an appropriate instrument to use when the task at hand requires cutting the metal into a particular profile. The machine, which is used to create metal sheets of a wide variety, is controlled by a computerized system and features an operator interface. It’s a multi-tool that may be used for cutting as well as shaping whatever material you’re working with.

The majority of establishments that employ this machine are those in the manufacturing and fabrication industries that work with metal.What Is a Mechanical Power Press?

Use Of Mechanical Press

This equipment for working with sheet metal has a wide range of applications across the board in the heavy sector due to its adaptability. In the past, the process of physically shaping the metal sheet required a great deal of time and work. The metal sheet, on the other hand, is able to be effortlessly cut, bent, pressed, and molded into a wide range of shapes and sizes with the assistance of a machine called a power press.

What Really Happens When You Use the Power Press Machine?

The concept of converting rotational momentum into linear motion is the foundation upon which the power press machine is constructed. The primary components include a clutch, a flywheel, a crankshaft, a stationary ram, and a moveable ram.

The Components of Mechanical Power Press

The following are important components of the power press controls

· The Base

The base of an inclined press performs the principal function of support and houses the mechanics that tilt and secure the frame.

· The Ram

Ram goes back and forth within its boundaries, which govern the magnitude of its strokes. You are able to tailor the stroke length as well as the amount of power that is supplied to meet your requirements. The desired operation on the workpiece can be carried out on the ram because it is fitted at its base with a punch that can be employed for the purpose.

· The Flywheel

Third, the end of the driving shaft that is furthest away from the rotating component houses the clutch that connects the flywheel to the driving shaft. When the punch is driven into the work, the flywheel is expected to release all of the energy it has built up during periods of inactivity in order to keep the ram moving at a consistent speed. Additionally, the flywheel is supposed to keep the punch moving at the same speed.

· The Clutch

The movement of the ram may be started and stopped thanks to the clutch, which is used to engage and disengage the driving shaft from the flywheel. This makes it possible to start and stop the movement of the ram.

· The Brakes

The fifth component is the clutch brakes, which are used to immediately halt the motion of the drive shaft in the event that it is disconnected from the flywheel.

The Fundamental Reasoning That Underlies Its Working:

The metal sheets are formed into the necessary forms with the assistance of combination dies that are mounted on the ram and bed of the press. A flywheel can be made to rotate thanks to a motor that drives it. A clutch is utilized in order to transfer the rotation of the flywheel to the crankshaft in an internal combustion engine.

The crankshaft is the component that connects the movement of the press ram, which moves up and down, to the rotation of the flywheel. After the tool cycle has started, the workpiece will next be put into the die to be cut. The action of applying pressure from both the upper and lower dies to the stock material results in the production of a freshly formed part.

When the downstroke has been finished, the workspace that was made is discarded, and a new plate shape is employed so that the procedure can be performed again.

What Different Applications Are There for Equipment Related To Power Presses?

Facilities devoted to manufacturing and engineering make up the majority of users. The usage of power presses is necessary for a wide variety of fields, including but not limited to the production of automobiles, farming, the fabrication of bicycles, mechanical engineering, and electrical engineering.

Every manufacturing and processing facility makes use of it due to the adaptability it offers in a variety of applications.What Is a Mechanical Power Press?

Because of how much simpler it simplifies the process of bending metal; it has found widespread application in the working world.

How Exactly Might One Benefit from Utilizing a Power Press Machine?

The use of the Power press will result in a significant reduction in the amount of time, effort, and labor required to execute the cutting and pressing that was previously performed by the labor.

· Having a layout that eliminates the need to repeatedly make adjustments to workpieces at different stages of production.

· Because of the adaptability of the layout, we are able to establish our base of operations pretty much wherever within the garage.

· This device has a very low amount of initial setup and ongoing maintenance requirements, and it is also quite easy to operate.

· This machine regularly delivers excellent results when it comes to pressing, punching, and clasping activities, despite the fact that it just requires a small amount of maintenance.

Important Safety Reminders Regarding Power Press Machines:

Because it is a somewhat weighty piece of equipment, running the Power Press machine requires some caution on your part due to a few potential hazards. Due to inadequate maintenance, the procedures are put at risk. Regarding the protection of the machines, particular focus is to be placed on the following particulars:

· You must make certain that anybody who uses a power press machine in your workshop has received the appropriate amount of training before you can guarantee their safety.

· Taking notes on a topic is another great way to learn about a machine’s inner workings and get a better understanding of its operation.

· It is quite necessary that you carry out routine inspections of the equipment’s functionality if you wish to make use of it without causing any mishaps.

· An experienced person can perform routine checks on the machine’s components to ensure that they are in working order.

· It is crucial to keep detailed records of all prior maintenance operations performed on your power press. This will allow you to book the next maintenance appointment for your power press in a timely manner.

· When the device is not being utilized, the power supply ought to have its switch switched off.

The GUANGDUAN Power Press Machine:

Now that you know what is a mechanical power press, you must also know that the GUANGDUAN power press machine is unrivaled in the industry in terms of both its quality and its price. The use of power press machines is prevalent across many different types of businesses.

Mechanical Press Machines of the best possible quality are produced, supplied, and exported by our company. We have power press machines that range in size, and the prices for all of them are very reasonable. Please get in touch with us if you have any inquiries regarding the expense of purchasing a power press machine. What Is a Mechanical Power Press?

Customers who are looking for high-powered and high-quality Power Press equipment need to go no further than the GUANGDUAN brand of Power Press machines. There is no need to seek any further than GUANGDUAN machine tools if you are in search of trustworthy power press machine manufacturers and suppliers. What Is a Mechanical Power Press?

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us