-

Home / Mechanical Press

Mechanical Press

What is a Mechanical Press?

A mechanical press is a machine press that is primarily used for forming sheet metal and metal extrusion. The mechanical press is not only used for sheet metals but also used for manufacturing plastic products and a variety of machining operations such as broaching. Machine press requires a great amount of output force to complete the metalwork, for example, to deform a considerable piece of metal. The type of energy source, the manner, and nature where the machine press will transfer the energy vary, defining the efficiency as well as the output the machine tool can provide.How Does Mechanical Press Work?

In short, the working principle of the mechanical press is to convert the rotational force from the electric motor to a translational force which drives the mechanism of pressing work. The energy source of the mechanical press machine is typically a motor. Using a mechanical press machine, there are 3 main steps to complete the metal forming process. The production cycle begins with the material placed on the dies where the metal sheet or other raw materials should stay in place for machining. The operators should then manipulate the mechanical press to apply appropriate pressure in order to force and shape or alter the raw materials as they need. Subsequently, the finished products will be ejected and collected from the mechanical machines. All components in a mechanical press require to be lubricated through the internal system, in general, which supplies a stable flow of lubricants to ensure smooth movement during the pressing process.Advantages

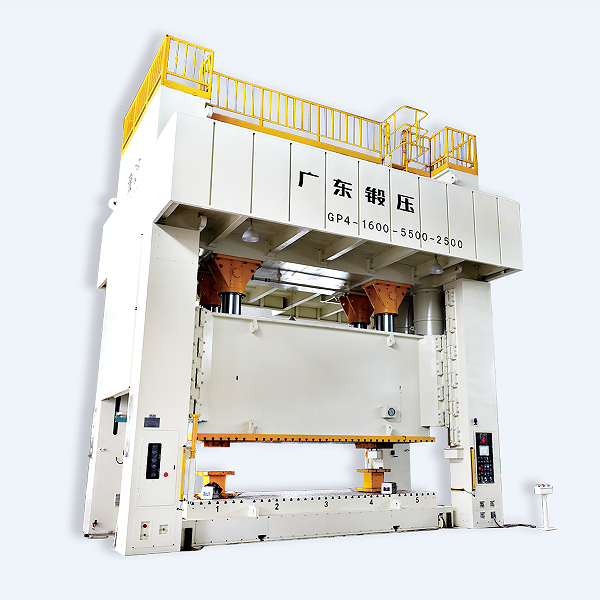

Guangduan has been the biggest mechanical power press machine manufacturer in Southern China for over 60 years. We are constantly pushing the industry forward with innovations in manufacturing, materials, and controls. We offer a full range of power mechanical presses up to 2000 ton capacities, with gap frames, straight sides, single and double point configurations, geared crankshaft drive with link motion, eccentric plunger guided with link motion to serve a wide variety of applications. All of our presses are built to exceed JIS's first-class standards.Mechanical presses are essential machines used in various industries to perform tasks such as punching, stamping, cutting, and forming. These machines offer high production speeds that allow for mass production, making them ideal for manufacturing processes. This article will provide an in-depth look at the different types of mechanical presses, their features, benefits, and applications.

Types of Mechanical Presses

1. C-Frame Presses

C-frame presses are characterized by their open-frame design, which allows easy access to the working area. They are suitable for a wide range of applications, including punching, forming, and bending operations. C-frame presses offer various benefits, such as compact size, easy installation, and affordability.

C-Frame Flywheel Presses

These presses feature a flywheel that directly drives the eccentric shaft, allowing for higher speeds and increased productivity in applications like punching and stamping.

C-Frame Quick Presses

Designed for high-speed operations, quick C-frame presses can reach up to 300 strokes per minute. They are ideal for applications requiring minimal intermediate gear reduction.

2. Straight Side Presses

Straight side presses feature a more rigid and stable construction, minimizing angular deflection and ensuring precision during operation. They are suitable for heavy-duty applications, including deep-drawing, progressive die, and transfer die operations.

Straight Side Eccentric Gear Mechanical Presses

These presses utilize eccentric gears to provide precise and reliable performance. They are designed for high-precision applications, such as blanking, embossing, bending, flanging, and coining.

Straight Side Two-Point Presses

Featuring a symmetrical front-rear column structure, these presses are ideal for high-speed, accurate operations involving light, thin materials.

3. Servo Presses

Servo presses are electric-powered machines that offer cleaner and quieter operation than pneumatic or hydraulic presses. They are designed for precise, user-friendly programming and can efficiently press-fit, swage, rivet, seal, cut, punch, bend, and crimp materials.

4. Hydraulic Presses

Hydraulic presses use hydraulic power to generate force and are known for their versatility and flexibility. They can be adjusted to suit various applications and are commonly used in industries such as automotive, aerospace, and electronics.

5. Mechanical Presses with Special Features

Some mechanical presses are designed with unique features to meet specific application requirements. Examples include presses with horizontal or vertical ridge-locking mechanisms, double-column eccentric presses, and presses with built-in force transducers for precise force measurement.

Applications of Mechanical Presses

Mechanical presses find applications in various industries due to their versatility and ability to perform a wide range of tasks. Some common applications include:

1. Automotive Industry

In the automotive industry, mechanical presses are used for tasks such as stamping body panels, forming engine components, and creating various other parts.

2. Aerospace Industry

These presses are used to manufacture airplane parts, such as wings, fuselage components, and engine parts, using materials like aluminum alloys and titanium.

3. Electronics Industry

Mechanical presses are used for precision operations in the electronics industry, such as cutting and forming circuit boards and other electronic components.

4. Metalworking Industry

These machines are widely used in the metalworking industry for cutting, punching, bending, and forming metal sheets, plates, and bars.

5. Jewelery and Watchmaking Industry

Mechanical presses are used for precision tasks in the jewelry and watchmaking industry, such as cutting, shaping, and engraving intricate designs.

Features and Benefits of Mechanical Presses

Mechanical presses offer various features and benefits, making them ideal for a wide range of applications:

1. High Production Speed

Mechanical presses are known for their high production speeds, which enable mass production and increased efficiency in manufacturing processes.

2. Precision and Accuracy

These machines offer high precision and accuracy during operation, ensuring that the final product meets the desired specifications and quality standards.

3. Versatility

Mechanical presses can be used for various tasks, such as cutting, punching, bending, forming, and more, making them suitable for numerous industries and applications.

4. Durability and Longevity

Mechanical presses are built with high-quality materials and components, ensuring a long service life and reliable performance.

5. Safety Features

These machines are equipped with safety features such as overload protection, electropneumatic clutch-brake combinations, and central motorized lubrication systems to ensure operator safety and prevent accidents.

Factors to Consider When Choosing a Mechanical Press

When selecting a mechanical press, it is essential to consider the following factors:

1. Press Capacity

Determine the press capacity required for your application based on the force needed to perform the task.

2. Stroke Length

Choose a press with a suitable stroke length based on the dimensions of the workpiece and the depth of the operation.

3. Speed Requirements

Consider the production speed required for your application and choose a press that can meet those requirements.

4. Press Type

Select the appropriate type of mechanical press based on the specific application and the desired features.

5. Budget

Consider the budget available for purchasing a mechanical press and select a machine that offers the best value for money.

Conclusion

Mechanical presses are versatile and efficient machines used in various industries for tasks such as cutting, punching, bending, and forming. They offer high production speeds, precision, and accuracy, making them ideal for mass production and precision operations. When choosing a mechanical press, it is essential to consider factors such as press capacity, stroke length, speed requirements, press type, and budget to select the best machine for your application.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us