Heavy Metal, Smarter Moves: How This Large Metal Forming Machine Is Saving Costs and Time

Large metal forming machine technology is no longer about brute force alone. It is about smart timing and precise control. Imagine pressing a steel plate with surgical accuracy while the clock ticks in your favor. This new giant does exactly that. Sensors guide every stroke. Software predicts wear before it happens. Operators see clear warnings on a bright screen instead of hearing them in the workshop echoes. The result is leaner energy bills and faster production cycles. Heavy metal still moves, but smarter moves now save you money, hours, and headaches. Maintenance becomes a quick checklist rather than a full shutdown.

Smarter Manufacturing in the Age of Precision

The New Role of Large Metal Forming Machines

In the past, a large metal forming machine relied mostly on raw force. Speed and accuracy were often sacrificed. Today, the industry is changing. Large machines must do more than just press hard. They must press smart. Modern systems combine strength with precision, allowing manufacturers to deliver quality parts faster and at lower cost.

The Industry‘s Drive Toward Cost and Time Efficiency

Manufacturers now demand high efficiency. They want machines that reduce waste, save energy, and shorten production cycles. A large metal forming machine with smart control systems can meet these needs. With fewer breakdowns and faster setup, factories save both time and money.

GUANGDUAN’s Smart Press Solution

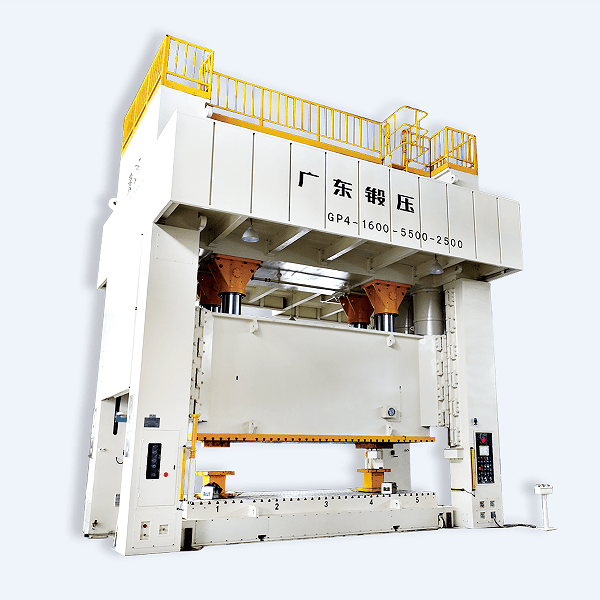

This is where GUANGDUAN steps in. We offer a next-generation solution: the Two-Point/Four-Point Single Acting Precision Mechanical Press. This large metal forming machine is built to work smarter, not just harder. It combines strong engineering with intelligent automation to help your business grow.

Meet the Machine: Two-Point/Four-Point Single Acting Precision Mechanical Press

Built for Power, Designed for Precision

The machine body of Two-Point/Four-Point Single Acting Precision Mechanical Press is made from steel plates through welding. Then it goes through high-temperature annealing. This gives the machine excellent rigidity and precision stability. Even during high-pressure forming, the large metal forming machine holds its shape and delivers steady results.

Tailored for Heavy-Duty Work

This press is made for tough jobs. It handles thick materials and complex shapes without losing accuracy. With advanced structural support and balance, it performs under pressure while keeping each stroke clean and exact.

Manufactured by GUANGDUAN

We at GUANGDUAN have been designing and building forming machines since 1958. After over 60 years, we have become the largest forging and pressing equipment manufacturer in South China. Our machines are used across many industries, helping companies achieve better results with less effort.

Precision Engineering in Every Stroke

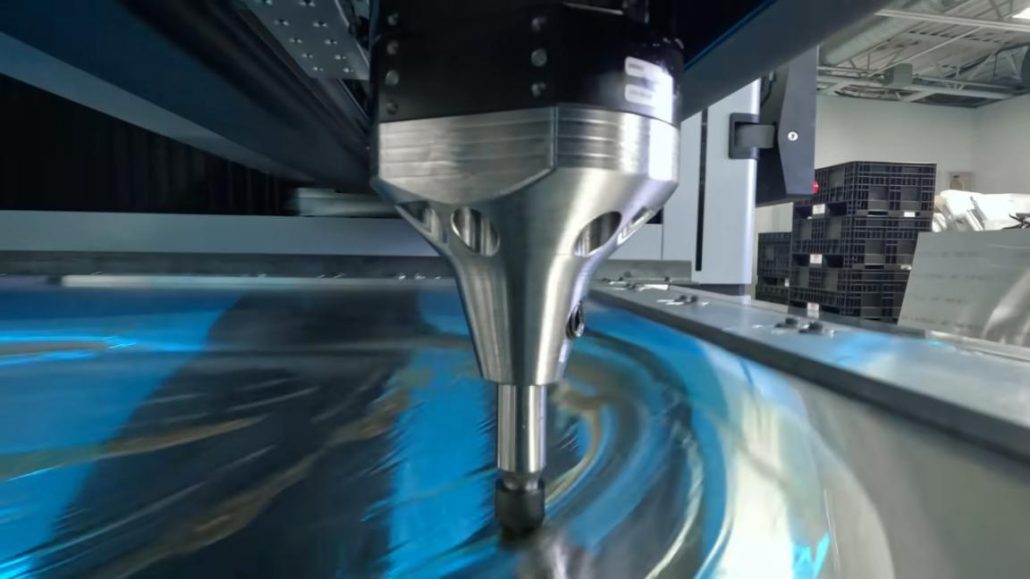

Eight-Surface Long Guideway Slide Design

The slide uses an eight-surface long guideway. This helps the large metal forming machine stay stable during operation. It reduces wear and supports smooth, straight movement. As a result, every part formed is consistent and accurate.

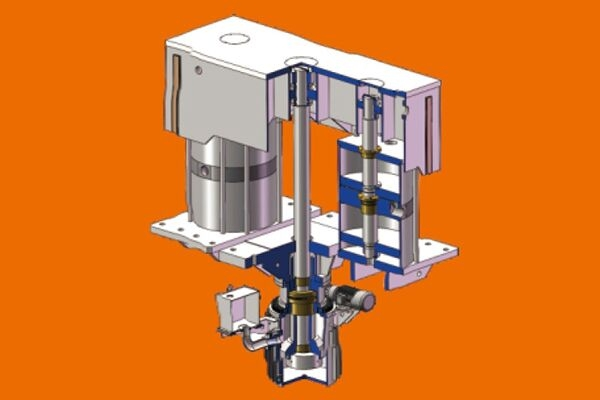

High-Tonnage Air Cushion System

This machine includes a high-tonnage air cushion made with pure gas. It supports a wide range of blank pressing and ejection tasks. The system also includes stroke adjustment and hydraulic buffering, which protects both the machine and the product.

PLC-Controlled Intelligence

Our large metal forming machine is controlled by a smart PLC system. It adjusts die height, air pressure, and cushion stroke automatically. Operators can make fast, safe changes through a clear control panel. This saves time and improves production flow.

Smart Transmission

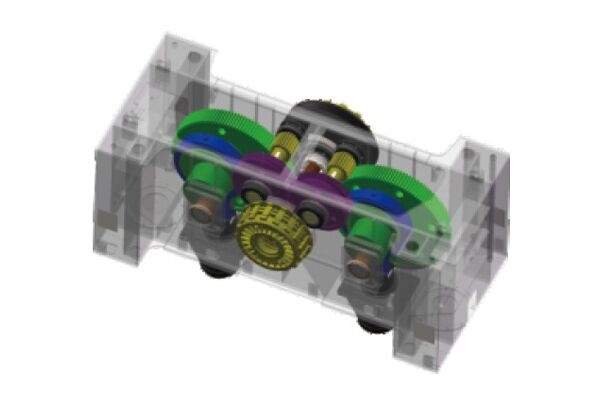

Five-Shaft Main Transmission System

The core of this large metal forming machine is its five-shaft main transmission system. This design improves balance and reduces internal stress. It helps the machine stay accurate, even during heavy-duty stamping. This structure also increases the machine’s ability to handle unbalanced loads without affecting output quality.

Symmetric Gear Arrangement for Power Distribution

The gears inside the machine are arranged symmetrically. This layout reduces side forces and keeps power evenly distributed. It makes the machine more stable during high-speed operations. Stability is key to long-term performance and consistent product quality in large-scale production.

Advanced Materials and Sealing

We use high-strength alloy steel and forged No.45 steel for the gears. Each gear goes through a strict heat treatment process. The large and small gears are designed with different hardness levels. This ensures better wear resistance and a longer service life. All moving parts are sealed for protection and reliable operation.

Efficiency in Setup and Maintenance

Self-Moving Work Table & Die Clamping System

This large metal forming machine is designed to save time. The self-moving work table helps operators position tools quickly and accurately. The automatic die clamping system reduces manual work and shortens setup time. This means more uptime and less waiting between jobs.

Automatic Lubrication System

To protect the machine, we use a thin oil circulating system. It works automatically and reaches every key part. Sensors monitor oil pressure, flow rate, and temperature. This smart system reduces wear, lowers noise, and helps extend the machine’s lifespan.

Easy Monitoring and Safety

Safety and control are built into every part of the machine. The control system shows real-time data like oil levels, temperature, and resistance. Operators receive alerts if anything goes outside the safe range. This reduces the risk of failure and keeps the production line running smoothly.

Customization and Automation Integration

Compatible with Auto Feeding and Leveling Devices

This large metal forming machine can be equipped with automatic feeding and leveling devices. These tools help create a fully automated stamping line. They reduce labor costs and increase production speed. With this system, your factory can run faster and more efficiently.

Flexible Air Cushion Features for Diverse Needs

The built-in air cushion uses a stroke-regulating design. It adjusts to different drawing processes without changing parts. A hydraulic buffer reduces impact and noise during operation. This helps protect the machine and the final product.

Lag Latching Cylinder for Special Draw Processes

For advanced applications, we offer an optional lag latching cylinder. This feature prevents the cushion from rising too fast. It protects delicate workpieces during high-speed motion. With this, your large metal forming machine can handle more complex tasks with ease.

Why GUANGDUAN Leads the Way

National and Provincial Recognition

We are proud of our history and our achievements. At GUANGDUAN, we have been recognized as a national high-tech enterprise and a key player in Guangdong’s equipment manufacturing industry. We have built research institutions like the “Guangdong Key Laboratory of Metal Forming” and the “Postdoctoral Research Station.” We continue to invest in science and technology.

A Backbone Enterprise with Global Vision

Founded in 1958, we have over 60 years of experience in metal forming. We are now the largest forging and pressing equipment manufacturer in South China. Our mission is clear: to deliver smart, reliable, and efficient machines to the world. Our large metal forming machines are already serving customers across multiple industries, helping them produce faster and smarter.

Conclusion: Smarter Machines Mean Smarter Business

In today’s fast-paced world, every second counts. A smart and powerful large metal forming machine like ours gives you a real edge. It saves time, reduces cost, and improves product quality. At GUANGDUAN, we don’t just build machines – we build solutions for the future of manufacturing.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us