How to Choose a Reliable Heavy Press Equipment Supplier

Reliable Heavy Press Equipment Supplier is more than a promise at Guangduan; it defines how we design, build, and support every press we deliver, from concept to commissioning and long-term service.

What Buyers Should Look For in a Reliable Heavy Press Equipment Supplier

Choosing a partner for heavy press equipment is a strategic decision. You are protecting uptime, die life, and part consistency. Price matters, but your total cost per part depends far more on engineering depth, production scale, and service reliability. A trustworthy supplier demonstrates stable precision under load, quick die changes, and controls that make setup repeatable. When these pieces align, your line runs predictably and your delivery dates stop slipping.

The biggest pain points in stamping are familiar: unplanned stops, drifting accuracy, and slow support. Each problem raises scrap and risk. The right partner prevents these issues with rigid frames, long-guideway slides, intelligent lubrication, and PLC-based control of critical parameters. Clear documentation and fast access to spare parts close the loop. This is what a Reliable Heavy Press Equipment Supplier should provide before you place an order.

✅ Use this quick checklist when you compare proposals:

- Proven investment in R&D and a track record measured in decades

- Large-scale machining capacity and third-party-traceable measurement systems

- ISO 9001 quality management and documented test routines

- Fast die-change design, with options for automation to stabilize takt

- Localized, quick-response after-sales support with clear service targets

Notice how the traits above tie directly to your KPIs. Better frames and slides hold tolerance. Robust lubrication lowers wear and noise. Smart controls reduce operator variability. Together, they compress commissioning time and protect long-run accuracy. If you also value supplier stability, ask for the organization’s research platforms, equipment list, and measurement credentials up front. A true precision mechanical press manufacturer will share them readily.

Why Guangduan Meets – and Often Exceeds – the Standard

Founded in 1958, Guangduan has grown into the largest forging and pressing equipment manufacturer in South China. We integrate R&D, manufacturing, and service as a national high-tech enterprise. Our research footprint includes a Postdoctoral Research Station, the Guangdong Forging Equipment Engineering Technology R&D Center, the Guangdong Provincial Enterprise Technology Center, and the Guangdong Key Laboratory of Metal Forming Processing and Forging Equipment Technology. We have undertaken nearly 60 science and technology projects at national, provincial, municipal, and district levels. This is how a Reliable Heavy Press Equipment Supplier keeps advancing core technology rather than standing still.

1) Deep R&D and Scalable Manufacturing

Our headquarters is in Shunde, with a wholly owned subsidiary – Wuzhou Wanshun Forging and Pressing Machine Tool Factory Co., Ltd. We employ more than 100 engineers and technicians, including 13 with senior titles, one at professor level, and over 60 engineers focused on product and process improvement. On the manufacturing side, we operate more than 200 sets of major production equipment. That includes floor boring and milling machines, gear grinding machines, crankshaft grinding machines, and machining centers – nearly 100 large, precision CNC units in total. For verification and alignment, we use more than 1,000 advanced measurement and testing devices such as large CMMs and laser tracking instruments. We also hold a second-level measurement qualification. This combination – capacity plus metrology – lets us build large frames, finish critical interfaces, and prove accuracy before shipment.

2) Quality Systems and Service You Can Measure

Guangduan is a leading enterprise in the forging and pressing industry and operates under ISO 9001 certification. Our processing workshop spans more than 30,000 m² and uses overhead cranes up to 125 tons. That scale supports large welded bodies and complex subassemblies without compromising rigidity. Equally important, our quick-response after-sales team helps stabilize ramp-ups and sustain throughput over the long term. Clear communication, documented maintenance plans, and fast parts supply shorten downtime windows. This is the practical value you should expect from a Reliable Heavy Press Equipment Supplier.

Inside the GP2/4 Series: Engineering That Protects Your Takt

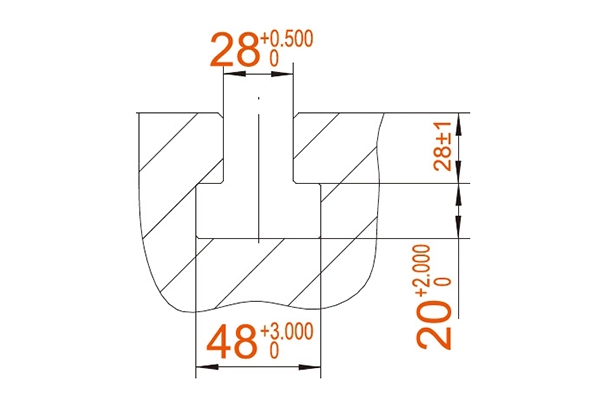

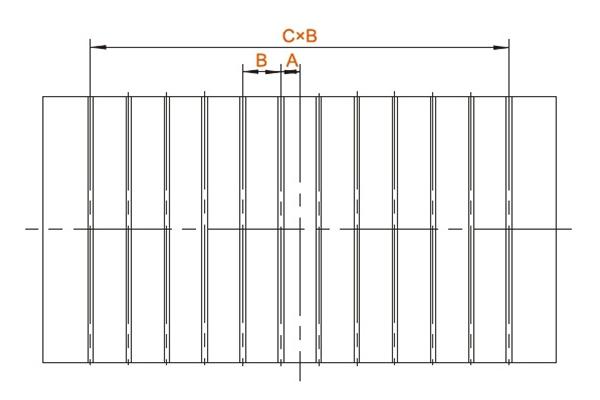

The STRAIGHT SIDE GP2/4 Series – our two-point and four-point single-acting precision mechanical presses – shows how detailed engineering turns into line performance. The machine body is welded from steel plates, then high-temperature annealed. The result is high rigidity and stable precision across long production runs. A self-moving work table and a die-clamping system shorten die changes. Changeovers consume less time, so your takt time stays steady even when you switch parts.

The slide uses an eight-surface long-guideway design. This guiding approach resists tilt and keeps the slide square through the stroke, which helps maintain die alignment and reduces edge wear. Over time, that stability shows up as consistent hole quality, straighter flanges, and cleaner trims.

Under the crown, the main transmission uses a five-shaft structure with symmetrically arranged gears. By enlarging the interval between left and right pressure points, the layout improves resistance to unbalanced loads often seen in real parts. Two-level speed reduction is adopted: a herringbone gear for the high-speed stage and a straight gear for the low-speed stage. Small gears use high-strength alloy steel. Large gears use No.45 forged steel with appropriate heat treatment. The different hardness pairing improves strength and wear resistance, extending service life in tough duty cycles.

Critical moving elements – main transmission gears and the connecting rod – are sealed inside the beam. They receive progressive thin-oil automatic circulating lubrication. Pressure, flow, temperature, oil level, and dogging resistance are monitored. Forced lubrication reduces wear and noise and enhances reliability, especially during long runs at nominal load. These are the quiet design choices that separate a general-purpose machine from a true Reliable Heavy Press Equipment Supplier solution.

Control strategy matters as much as mechanics. Our PLC-based system automatically adjusts air pressure, die set height, and air cushion stroke. Standardized setup raises the level of automation and trims operator variability. The air cushion is a large-tonnage, pure-gas design. It includes stroke regulation and can be configured with a lag latching cylinder when the drawing process requires it. Hydraulic terminal buffering reduces impact and noise, which supports better surface quality and longer die life. The air cushion also uses progressive interval thin-oil lubrication for stability under long-period full load.

If you target higher OEE, the GP2/4 platform can integrate automatic feeding and uncoiling/leveling devices to achieve automated stamping on a single machine. This path is practical when you need consistent takt without adding headcount. It is also a natural fit for programs that specify a two-point four-point press and require repeatability over many thousands of cycles.

In short, the machine’s body, slide guidance, transmission, lubrication, and controls work together. They reduce setup time, control deflection, and keep the die in the ideal window. That is how you protect parts, shorten debug time, and achieve predictable output.

Call to Action

Planning a new line or upgrading an existing cell? Share your tonnage, stroke, and die-handling requirements with Guangduan. We will recommend the right GP2/4 configuration, define options around feeding and die change, and validate capacity with our measurement resources. Connect with a Reliable Heavy Press Equipment Supplier today for a technical consultation or a tailored proposal.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us