Why Choose a Crankshaft Press for Server Chassis Assembly

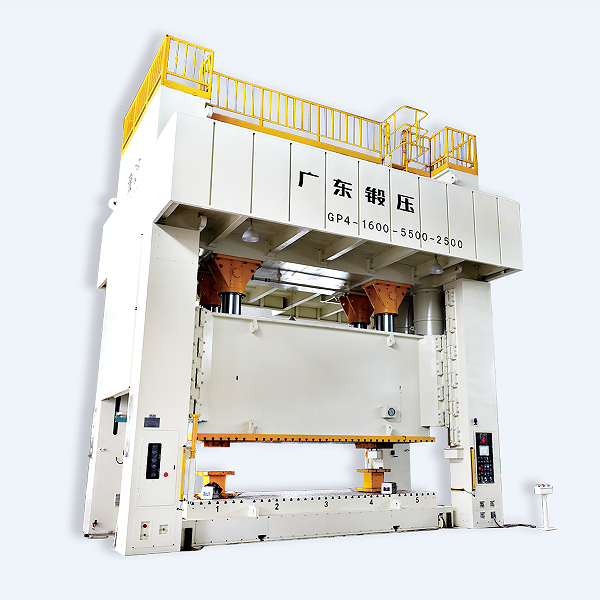

Crankshaft Press For Server Chassis is more than a machine; it is the backbone of stable, repeatable assembly. Server housings are thin. Tolerances are tight. Changeovers are frequent. Every minute of downtime costs money. A crankshaft press brings order to this chaos. It delivers clean forms, steady force, and predictable quality. It also scales with new SKUs and faster takt times. But what makes one press truly stand out? And why do leading plants choose it for high-mix server chassis lines? As Guangduan, we build presses that keep data-center hardware lines on time, on spec, and under budget. Thin sheet, tight hole locations, and frequent die swaps create everyday risk. The right crankshaft press turns those risks into routine wins – higher precision, lower scrap, and fewer unplanned stops.

Built For Repeatable Precision In Server Chassis Lines

Server chassis forming rewards rigidity and punishes flex. Our two-point and four-point single-acting precision mechanical presses use a welded steel body that is heat-treated at high temperature. This sequence locks in stiffness and holds accuracy for long campaigns. The slide runs on an eight-surface long-guideway, so alignment stays true even when parts present unbalanced loads across wide panels.

Changeovers matter as much as stroke count. A self-moving worktable and a quick die-clamping system reduce idle time when shifting between SKUs. Operators set air pressure, die height, and air-cushion stroke through PLC control, so recipes load in seconds and repeat across shifts. Add automatic feeding with uncoiling and leveling, and a single machine can run fully automated stamping for most chassis parts.

What that means on your floor:

- Faster changeovers with integrated clamping and a movable table

- Stable accuracy from annealed frames and long-guideway slides

- Consistent setups via PLC recipes and automatic adjustments

- Clean hand-off to downstream tapping, riveting, and assembly

n What Sets Guangduan Apart

We design for uptime first. Sensors monitor oil pressure, flow, temperature, and tank level. Maintenance teams see issues before they stop the line. Materials are specified for load paths, not price tags – high-strength alloy small gears, No.45 forged steel large gears, and targeted heat treatment to extend service life. For you, this is less firefighting and more production.

Inside The Machine

- Five-Shaft Main Drive For Stability

At the heart of our Crankshaft Press For Server Chassis is a five-shaft transmission arranged in different directions with symmetrically placed gears. This geometry counteracts gear inertia and connecting-rod side forces, keeping each stroke smooth and predictable. The wider spacing between left and right pressure points boosts resistance to off-center loading – common with asymmetrical blanks and large rack panels.

Power arrives where it should. A two-stage reduction uses herringbone gears at the high-speed stage for quiet, low-vibration transfer, and straight gears at the low-speed stage for robust torque. Hardness is matched across the train – harder small gears, properly treated large gears – so wear distributes as intended. The gear set and connecting rod are sealed inside the beam and force-lubricated by a progressive thin-oil system. Noise drops, friction falls, and parts keep moving.

✅ Drive-train advantages at a glance:

• High accuracy under offset or unbalanced loads

• Lower noise and reduced wear with forced lubrication

• Longer service intervals from matched materials and heat treatment

- Pure-Gas Air Cushion With Intelligent Control

Draws and forms live or die by cushion behavior. Our large-tonnage, pure-gas air cushion uses a single apical cap with two main cylinders, a stroke regulator, and terminal buffering. One standard-length ejector rod can cover different draw depths by simple stroke adjustment. That means fewer tool changes, faster cycle tuning, and gentler part handling.

Hydraulic terminal buffering reduces impact at the end of stroke to protect both die and workpiece. Progressive interval thin-oil lubrication maintains stability at full load during long production runs. For deep-draw chassis components, an optional lag-latching cylinder prevents damage from rapid cushion rise – small device, big improvement in draw quality.

- Controls That Make Precision Repeatable

Precision must be easy to repeat. With PLC-based control, operators load a part recipe, confirm die height, set cushion parameters, and start production with minimal manual tuning. The result is shorter first-article approval and consistent panel flatness from first hit to last. Shops with mixed experience levels benefit most: quality no longer depends on one expert being on shift.

Deploy With Confidence

A Crankshaft Press For Server Chassis has to match your takt time, staffing, and part mix – not the other way around. We help you map the real constraints. Start with automated feeding and uncoiling-leveling on a single press. Build standard recipes for your top chassis families. Validate cushion curves for each draw. Then scale: add coil stations, extend die carts, or integrate downstream fastening cells when volume rises.

Finance teams look for durable assets, not maintenance projects. The sealed gear train, progressive lubrication, and condition monitoring protect the press’s core value. Quality teams need predictable flatness, hole location, and edge integrity. The rigid straight-side GP2/4 frame and long-guideway slide make that predictability the default. Operations leaders want fewer stoppages and faster changeovers; the quick clamping and movable table deliver both.

Operational outcomes you can plan on:

• Fewer bottlenecks from rapid die swaps and recipe-based setups

• Better first-pass yield through stable guidance and controlled draws

• Lower lifecycle cost from robust transmission and proactive lubrication

- Implementation Roadmap You Can Run This Quarter

Week one, we review drawings and part families to confirm tonnage, point configuration (two-point or four-point), and cushion force. Week two, we define the feeding and leveling plan and align PLC recipes with your quality checkpoints. Week three, we train operators on die change, lubrication checks, and fault codes. By week four, you are running production parts with documented settings and a clear maintenance routine.

Final Words

If your chassis line needs fewer surprises and more throughput, talk with a Guangduan application engineer. We will evaluate your parts, recommend the right Crankshaft Press For Server Chassis configuration, and help you lock in the process window – before the first coil hits the uncoiler.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us