Auto Parts Manufacturing Equipment Enhanced by Four-Point Press

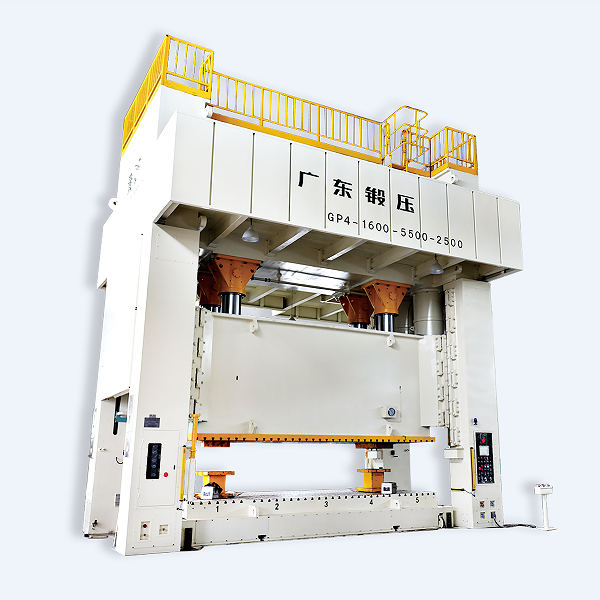

At GUANGDUAN, we understand that precision and efficiency are key to success in the ever-evolving auto parts manufacturing industry. As the demand for high-quality automotive components rises, so does the need for advanced machinery. Our latest innovation in auto parts manufacturing equipment, the Four-Point Precision Mechanical Press, is designed to meet the growing demands of manufacturers while improving productivity, precision, and reliability. This article will explore the technical upgrades of our four-point press, its advantages in the manufacturing process, and how it significantly improves auto parts production efficiency.

The Evolution of Auto Parts Manufacturing Equipment

Auto parts manufacturing equipment plays a crucial role in the automotive industry’s supply chain. As production volumes increase, so does the necessity for reliable, high-precision machinery capable of handling various tasks, from blank pressing to stamping. The introduction of the Four-Point Single Acting Precision Mechanical Press has marked a significant milestone in enhancing the performance of such equipment.

❓ What Makes the Four-Point Press Different?

The most notable feature of our Four-Point Press is its robust, precise structure. The machine body is constructed through the welding of high-strength steel plates, followed by high-temperature annealing. This process ensures the rigidity of the structure, enhancing both the machine’s stability and its precision. The result is a piece of equipment that guarantees high-quality, consistent results throughout the production cycle. The machine is also equipped with a self-mowing work table and die clamping system, improving the efficiency of die changes. This upgrade is particularly beneficial for manufacturers aiming to minimize downtime and maximize productivity.

Key Features of the Four-Point Press

Precision and Stability

The Four-Point Press is designed to provide the highest levels of precision and stability in auto parts manufacturing. Here’s how:

✅Rigidity and Stability: Through the high-temperature annealing of the steel plates used in the machine body, the rigidity and overall stability are significantly improved. This results in consistently high-quality output, reducing the likelihood of errors or defects.

✅Eight-Surface Long-Guideway Guiding System: The slide of the machine features an eight-surface long-guideway system, which contributes to the precision and stability of the production process. By ensuring smooth and accurate movements, this feature guarantees that every product is made to specification.

✅Symmetrical Gear Structure: The gear structure of the press is arranged symmetrically to counteract side forces, providing a balanced, stable performance. This feature contributes to reducing the wear and tear of components, extending the press’s operational life.

High Efficiency with Enhanced Die Clamping and Air Cushion Systems

Efficiency is critical for manufacturers who rely on high-volume production runs. The Four-Point Press addresses this need by incorporating several advanced features that streamline production processes.

✅Self-Mowing Work Table: This feature enables the automatic cleaning of the work surface, preventing material buildup and ensuring smoother production. It also enhances the machine’s longevity by reducing the wear and tear on components.

✅Die Clamping System: Our die clamping system makes the die-changing process faster and more efficient, ensuring minimal downtime. This system also helps reduce the chance of human error during the setup, making it an excellent solution for improving productivity.

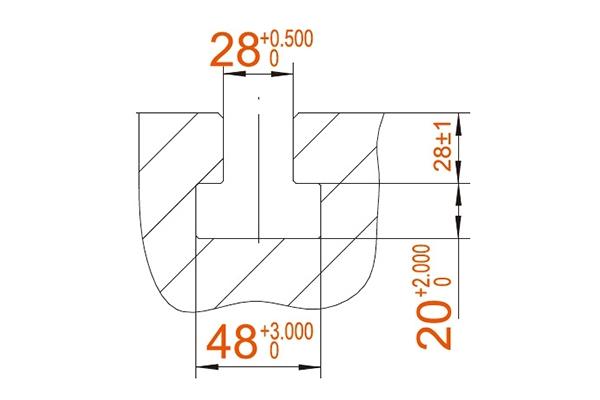

✅Large-Tonnage Air Cushion: The large-tonnage air cushion system uses pure gas and a single-apical cap structure to support various drawing and pressing demands. It ensures stable ejection and a smooth process, even under heavy loads.

Automation and Control: Redefining Productivity

Our Four-Point Press incorporates cutting-edge automation to further enhance productivity. The PLC control system is one of the standout features, offering automatic adjustment of key parameters such as air pressure, die set height, and air cushion stroke. This fully automated process minimizes manual intervention, reduces errors, and ensures the highest efficiency in operation.

✅Progressive Thin Oil Lubrication System: The press is equipped with an advanced lubricating system that automatically circulates thin oil, reducing friction and wear. This helps in maintaining optimal machine performance, lowering noise levels, and prolonging the service life of the equipment.

✅Advanced Monitoring System: The press includes built-in monitoring functions for pressure, flow rate, temperature, and oil levels. This system ensures that the machine operates within optimal parameters, allowing for continuous, high-quality production without interruptions.

The Benefits of Upgrading to GUANGDUAN‘s Four-Point Press

Upgrading your auto parts manufacturing equipment with our Four-Point Press brings a range of benefits that can elevate your production process. Whether you’re looking to enhance the quality of your products, improve efficiency, or minimize downtime, this press is engineered to deliver results.

❓ Why Choose GUANGDUAN‘s Four-Point Press?

Enhanced Precision and Stability: Thanks to its steel plate welding and high-temperature annealing, the press offers superior rigidity and stable precision, which translates into better product quality and consistency.

• Increased Production Efficiency: With features like the self-mowing work table, die clamping system, and large-tonnage air cushion, this machine is designed for seamless and efficient production. Die change times are reduced, and setup errors are minimized.

• Automation for Streamlined Operations: The PLC control system and the automatic lubrication feature reduce the need for manual interventions, allowing for higher productivity and lower operational costs.

• Long-Term Durability: The high-quality materials used in the construction of the machine, combined with its self-lubricating and easy-to-maintain design, ensure that the equipment will perform reliably for many years.

• Versatile Applications: Whether you’re involved in pressing, blanking, or stamping, the Four-Point Press offers unmatched flexibility, making it an excellent choice for a wide variety of auto parts manufacturing needs.

Conclusion

The Four-Point Press from GUANGDUAN represents a major leap forward in the evolution of auto parts manufacturing equipment. Its innovative design and advanced features offer significant improvements in precision, efficiency, and automation. Manufacturers who upgrade to this press can expect enhanced product quality, reduced downtime, and increased profitability.

As the automotive industry continues to evolve, having reliable and high-performance equipment like the Four-Point Press will be crucial for staying competitive in the market. At GUANGDUAN, we are committed to providing the best in class solutions to help you meet the ever-growing demands of auto parts manufacturing. Stay ahead of the curve by upgrading to the latest in precision machinery today.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us