How Do Advanced Advanced Hydraulic Forging Press for Metalworking Adapt to Custom Projects?

In the dynamic world of metalworking, innovation is key to staying ahead of the curve. As industries evolve and demands grow, the need for efficient and precise metal forging processes becomes increasingly paramount. Enter the Advanced Hydraulic Forging Press for Metalworking, a game-changing solution that promises to elevate metalworking capabilities to unprecedented levels. Manufactured by GUANG DUAN, this cutting-edge technology represents a significant leap forward in the field of metal forging. Let’s delve deeper into how this advanced machinery is reshaping the landscape of metalworking.

Understanding Metalworking Needs

1.1 Enhancing Efficiency and Precision

In the realm of metalworking, efficiency, and precision are non-negotiable. Manufacturers strive to streamline their processes while maintaining the highest standards of quality and accuracy. Traditional forging methods often face limitations in terms of speed, control, and consistency. As a result, there has been a growing demand for innovative solutions that can address these challenges head-on.

1.2 Meeting Diverse Industry Demands

Metalworking encompasses a wide array of industries, each with its own unique requirements and specifications. From automotive and aerospace to construction and manufacturing, the demand for forged metal components spans across various sectors. Consequently, there is a pressing need for forging machinery that can adapt to the diverse needs of different industries and deliver optimal results across the board.

1.3 Embracing Technological Advancements

In an era defined by rapid technological advancement, metalworking processes cannot afford to remain stagnant. Industry leaders are constantly exploring new technologies and techniques to enhance productivity, efficiency, and quality. Hydraulic forging presses have emerged as a cornerstone of modern metalworking, leveraging advanced engineering and automation to revolutionize the way metal components are forged.

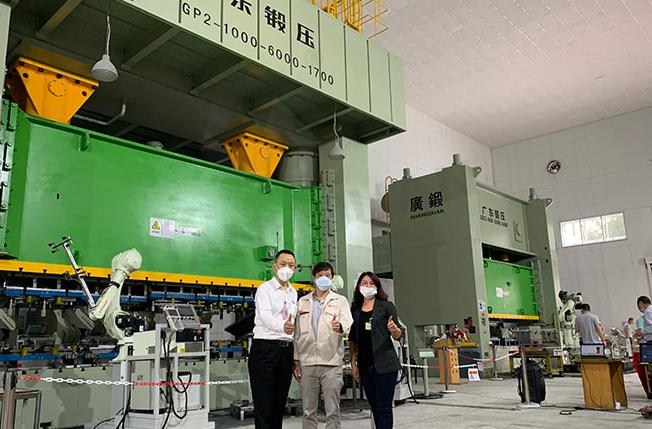

Introducing GUANG DUAN’s Advanced Hydraulic Forging Press for Metalworking

2.1 Innovative Design and Engineering

At the forefront of this technological revolution is GUANG DUAN’s Advanced Hydraulic Forging Press for Metalworking. Renowned for its innovative design and engineering excellence, this state-of-the-art machinery sets new benchmarks in performance and reliability. Equipped with cutting-edge hydraulic systems and precision controls, it offers unparalleled versatility and efficiency in metal forging applications.

2.2 Customizable Solutions

One size does not fit all in the world of metalworking. Recognizing the diverse needs of its customers, GUANG DUAN offers customizable solutions tailored to specific requirements. Whether it’s the size, capacity, or functionality, clients can collaborate with GUANG DUAN’s team of experts to design a hydraulic forging press that meets their exact specifications. This level of customization ensures optimal performance and maximizes return on investment for businesses across various industries.

2.3 Advanced Features and Capabilities

The Advanced Hydraulic Forging Press for Metalworking from GUANG DUAN is packed with a host of advanced features and capabilities. From real-time monitoring and feedback systems to intelligent automation and predictive maintenance, every aspect of the machinery is meticulously engineered to deliver exceptional results. With precise control over parameters such as pressure, temperature, and speed, operators can achieve consistent forging outcomes with minimal variance.

Unleashing the Potential of Hydraulic Forging Press

3.1 Enhanced Productivity and Throughput

One of the primary benefits of GUANG DUAN’s 2024 Latest Advanced Hydraulic Forging Press for Metalworking is its ability to significantly enhance productivity and throughput. By leveraging hydraulic power, the press can exert immense force with unparalleled precision, allowing for rapid shaping and forming of metal components. This results in shorter cycle times, increased output, and ultimately, greater efficiency in metalworking operations.

3.2 Improved Quality and Consistency

Consistency is the hallmark of excellence in metalworking. With traditional forging methods, achieving uniformity across batches can be a challenge. However, the advanced controls and monitoring systems integrated into GUANG DUAN’s Hydraulic Forging Press ensure consistent results with every cycle. From dimensional accuracy to material integrity, manufacturers can rely on the press to deliver high-quality forged components that meet the strictest standards.

3.3 Reduced Waste and Downtime

In addition to boosting productivity and quality, the Advanced Hydraulic Forging Press also helps minimize waste and downtime. Its precision controls and feedback mechanisms minimize material waste by optimizing the forging process and reducing the need for rework. Furthermore, predictive maintenance features identify potential issues before they escalate, allowing for proactive maintenance and minimizing unplanned downtime.

Structural Excellence: The Foundation of Performance

4.1 Robust Construction for Superior Rigidity

At the heart of the GY2S Series Hydraulic Press lies a robust and durable frame constructed from a high-quality steel welded box structure. This design not only ensures exceptional rigidity but also enhances the overall stability of the press during operation. The sturdy frame provides a solid foundation for precise forging processes, allowing manufacturers to achieve unparalleled accuracy and consistency in their metalworking endeavors.

4.2 Optimized Slider Design for Enhanced Precision

The slider, a critical component of any hydraulic press, is engineered to perfection in the GY2S Series. Constructed from a steel plate welded box structure, the slider boasts exceptional strength and durability to withstand the rigors of heavy-duty forging operations. Moreover, its eight-sided full guide rail guide ensures superior precision and retention, enabling manufacturers to maintain tight tolerances and produce high-quality forged components with utmost accuracy.

4.3 Efficient Lubrication System for Seamless Operation

To ensure smooth and uninterrupted operation, the GY2S Series Hydraulic Press is equipped with a thin oil continuous circulation lubrication system. This innovative system provides continuous lubrication to key components, minimizing friction and wear, and prolonging the lifespan of the press. By reducing maintenance requirements and downtime, manufacturers can maximize productivity and optimize their metalworking processes for greater efficiency and profitability.

Precision Control: Redefining Performance Standards

5.1 Servo Closed Loop Control System for Unrivaled Precision

At the core of the GY2S Series Hydraulic Press is a sophisticated servo closed loop control system, comprising servo motor driver, pressure sensor, displacement sensor, and PLC. This advanced system delivers unmatched precision, with minimal noise, vibration, and energy consumption. By precisely controlling pressure and displacement, manufacturers can achieve precise forging outcomes with exceptional repeatability, ensuring consistent quality across every batch of forged components.

5.2 Intelligent Control Interface for Enhanced Operability

The GY2S Series Hydraulic Press is designed for maximum usability and convenience, thanks to its intelligent control interface. Utilizing a PL a servo system + touch screen + grating ruler control mode, operators can make real-time digital adjustments with ease. The touch screen interface allows for intuitive parameter settings, with the capability to store up to 20 sets of mold parameters in the system. This level of flexibility and customization empowers manufacturers to adapt quickly to changing production requirements and optimize their workflows for maximum efficiency.

5.3 Advanced Safety Features for Peace of Mind

Safety is paramount in any metalworking environment, and the GY2S Series Hydraulic Press is equipped with an array of advanced safety features to ensure operator protection and peace of mind. The machine features a slider locking device that secures the slider at any position, preventing accidental movement during operation. Additionally, it is equipped with lower limit switch protection and anti-repetition of the two-handed hands, along with multi-level protection mechanisms such as anti-error protection in the touch screen parameter setting. These safety features not only safeguard personnel but also prevent costly accidents and downtime, ensuring smooth and uninterrupted operation of the press.

Conclusion

In conclusion, the Advanced Hydraulic Forging Press for Metalworking from GUANG DUAN stands as a testament to the power of innovation in metalworking. With its advanced features, customizable solutions, and transformative capabilities, it is poised to redefine the standards of excellence in the field of metal forging. As industries continue to evolve and demand for high-quality forged components grows, this revolutionary machinery will undoubtedly play a pivotal role in shaping the future of metalworking.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us