-

Home / Hydraulic Press

Hydraulic Press

What is a Hydraulic Press Machine?

A hydraulic press machine is a press that uses a hydraulic cylinder to generate a compressive force. Instead of a mechanical lever, a hydraulic equivalent is used in a hydraulic press.How does a Hydraulic Press Machine Work?

The automatic hydraulic press machine is based on Pascal’s Principle, defined as “A change in pressure at any point in an enclosed fluid at rest is transmitted undiminished to all points in the fluid”. The components of an automatic hydraulic press machine include cylinders, pistons, and hydraulic pipes. The working of the press is quite simple and primitive. The system comprises two cylinders that are filled with fluid. The fluid present inside the two cylinders is usually oil. The fluid (the oil) is filled into the smaller cylinder, which is also known as the slave cylinder. A piston is inserted into the slave cylinder and pressure is applied. The pressure applied causes the fluid to move through a pipe and into a larger cylinder. The larger cylinder is known as the master cylinder. The pressure exerted on the master cylinder and the piston in the master cylinder pushes the fluid back to the slave cylinder. The force applied to the fluid by the slave cylinder results in a large force, which is experienced by the master cylinder. An industrial automatic hydraulic press machine comes along with what is known as the press plates. With the help of these press plates, the material to be worked on is either punched or crushed into sheets.Applications of a Hydraulic Press Machine

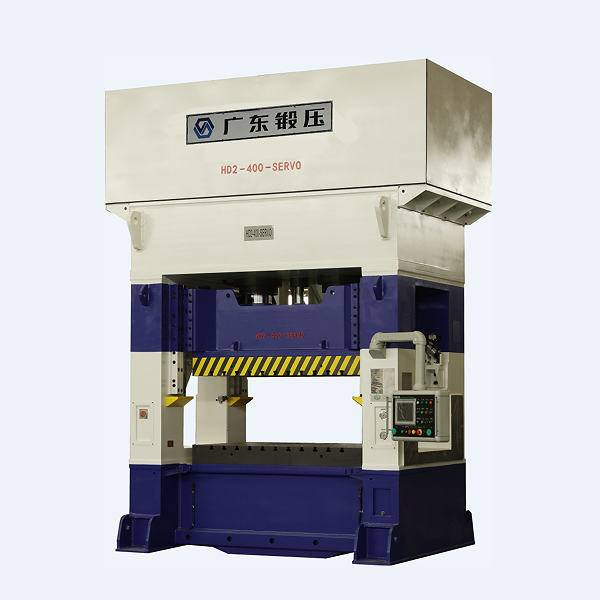

Guangduan has more than 30 years of experience in hydraulic presses. We offer a full range of hydraulic presses up to 10000 tons capacities, with four-post, straight sides to serve a wide variety of applications. Our combination of active fluid management and advanced servo motors adjusts fluid volume and motor speed to match the workload required, optimizing press performance while greatly reducing energy consumption.Hydraulic presses are powerful machines that use hydraulic cylinders to generate strong compressive force. They are widely used in various industries for a range of applications, including maintenance, fabrication, and assembly operations. This comprehensive guide will delve into the workings of hydraulic presses, their components, types, applications, and more.

Introduction to Hydraulic Presses

A hydraulic press, also known as a shop press, is a machine that uses hydraulic cylinders to apply significant compressive force to a workpiece. This force can be used to bend, straighten, flatten, or stamp the workpiece, making hydraulic presses versatile tools for various industries. Typically, hydraulic presses are mounted on the floor or a workbench and feature a plate or bed that holds the workpiece in place.

Primary Keyword: Hydraulic Press (1)

How Hydraulic Presses Work

The fundamental principle behind hydraulic presses is Pascal’s Law, which states that pressure change in a confined fluid is transmitted equally and undiminished throughout the fluid. In a hydraulic press, this principle is utilized to convert a small amount of force applied to a small piston into a larger force exerted by a larger piston.

A hydraulic press consists of two connected cylinders – a smaller one called the “slave” cylinder and a larger one called the “master” cylinder. When force is applied to the slave cylinder, it creates pressure in the hydraulic fluid, causing the fluid to flow into the master cylinder. As the fluid moves, it generates a larger force in the master cylinder, which is then applied to the workpiece.

Components of a Hydraulic Press

A hydraulic press is composed of several key components that work together to generate the compressive force needed for various applications. These components include:

Hydraulic Cylinders

Hydraulic cylinders are the main components responsible for generating force in a hydraulic press. They consist of a cylinder barrel, a piston, and a piston rod. The piston is connected to the piston rod, which extends through one end of the cylinder barrel. As hydraulic fluid is pumped into the cylinder, the piston moves, either extending or retracting the piston rod and generating force.

Hydraulic Fluid

The hydraulic fluid is an essential component of a hydraulic press, as it is responsible for transferring force between the cylinders. It must have specific properties, such as low compressibility and high thermal stability, to ensure the efficient operation of the press.

Hydraulic Pump

The hydraulic pump is responsible for supplying the hydraulic fluid to the cylinders. It converts mechanical energy into hydraulic energy by forcing the fluid through the system, creating pressure and flow.

Valves

Hydraulic valves are crucial for controlling the flow of hydraulic fluid within the press. They regulate the direction, pressure, and flow rate of the fluid, ensuring the proper operation of the hydraulic press.

Control System

The control system is responsible for coordinating the various components of the hydraulic press. It manages the operation of the valves, pump, and cylinders, ensuring the press operates efficiently and safely.

Types of Hydraulic Presses

Hydraulic presses can be categorized into several types based on their design and function. Some of the most common types include:

C-Frame Presses

C-frame presses have a C-shaped frame, which allows for easy access to the workpiece from three sides. They are typically used for applications that require a smaller pressing area and are popular in industries such as automotive and aerospace.

H-Frame Presses

H-frame presses have an H-shaped frame, which provides greater stability and support for larger workpieces. They are typically used for applications that require a larger pressing area and higher tonnage capacities, such as heavy-duty manufacturing and metal fabrication.

Four-Column Presses

Four-column presses have four columns supporting the press structure, ensuring even distribution of force and precise alignment. They are commonly used for high-precision applications, such as die-cutting and molding.

Benchtop Presses

Benchtop presses are compact hydraulic presses that can be mounted on a workbench or table. They are ideal for smaller-scale operations and applications that require precision and control, such as jewelry making and laboratory testing.

Applications of Hydraulic Presses

Hydraulic presses are versatile machines that can be used for a wide range of applications across various industries. Some common applications include:

Metal Forming

Hydraulic presses are widely used in the metal forming industry for processes such as bending, stamping, and deep drawing. They are capable of applying the high levels of force and pressure required to shape metal parts and components accurately.

Assembly Operations

In assembly operations, hydraulic presses can be used to press-fit components together, ensuring tight tolerances and proper alignment. They are commonly used in the automotive and aerospace industries for assembling parts and sub-assemblies.

Plastic and Rubber Molding

Hydraulic presses are used in the plastic and rubber molding industries for processes such as compression molding, injection molding, and transfer molding. They provide the precise temperature and pressure control required for these processes.

Laminating and Plywood Manufacturing

In the wood industry, hydraulic presses are used for laminating layers of wood or other materials together, as well as for the manufacturing of plywood. They provide the necessary pressure and heat to ensure strong adhesion and consistent quality.

Laboratory Testing

Hydraulic presses are also used in laboratory settings for various testing applications, such as material compression testing and sample preparation for analytical testing.

Safety Measures for Hydraulic Press Operation

Operating a hydraulic press requires strict adherence to safety measures to prevent accidents and ensure the well-being of workers. Some essential safety measures include:

Proper Training and Supervision

Operators should be adequately trained in the safe operation of hydraulic presses and must be supervised by experienced personnel.

Regular Maintenance and Inspection

Routine maintenance and inspection of hydraulic presses are crucial for ensuring their safe and efficient operation. This includes checking for leaks, wear, and damage to components, as well as ensuring proper fluid levels and pressure settings.

Protective Equipment

Operators should wear appropriate protective equipment, such as safety glasses, gloves, and steel-toed shoes, to minimize the risk of injury.

Safe Work Practices

Operators should follow safe work practices, such as ensuring the work area is clear of obstructions and maintaining a safe distance from the press during operation.

Advantages and Disadvantages of Hydraulic Presses

Hydraulic presses offer several advantages over other types of presses, such as mechanical and pneumatic presses. However, they also come with some disadvantages.

Advantages

- High force output: Hydraulic presses can generate a significant amount of force, making them suitable for various heavy-duty applications.

- Precise control: Hydraulic presses offer precise control over force, speed, and pressure, allowing for accurate and consistent results.

- Versatility: Hydraulic presses can be used for a wide range of applications and can be easily customized to suit specific requirements.

- Energy efficiency: Hydraulic presses can be more energy-efficient than other types of presses, as they only consume power when force is being applied.

Disadvantages

- Cost: Hydraulic presses can be more expensive than other types of presses, both in terms of initial investment and ongoing maintenance costs.

- Potential for leaks: Hydraulic presses rely on hydraulic fluid to generate force, which can lead to leaks and potential environmental contamination.

- Slower operation: Hydraulic presses can have slower cycle times compared to other types of presses, such as mechanical presses.

Conclusion

Hydraulic presses are versatile and powerful machines that play a crucial role in various industries. By understanding their components, types, applications, and safety measures, operators and businesses can make informed decisions about the best hydraulic press for their specific needs. With proper maintenance and operation, hydraulic presses can provide consistent and accurate results for a wide range of applications.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us