How Does Chinese Stamping Press for Metalworking Industry Address the Diverse Needs?

The GK Series knuckle joint press from GUANG DUAN exemplifies the company’s commitment to innovation and excellence in the metalworking industry. With its advanced features, precision engineering, and versatile capabilities, the Chinese Stamping Press for Metalworking Industry GK Series offers manufacturers a reliable solution for their forging and forming needs. As the metalworking industry continues to evolve, GUANG DUAN remains at the forefront, providing cutting-edge machinery that enables manufacturers to stay competitive in a rapidly changing market.

Current Status of the Global Metalworking Market

1.1 Expanding Market Due to Rising Industrialization

The global metalworking market is witnessing significant growth, driven primarily by increasing industrialization. With the advent of new industries and the expansion of existing ones, the demand for precision-engineered metal parts is on the rise. This growth is particularly notable in sectors such as automotive, aerospace, electronics, and construction, where precision and reliability are paramount. As these industries evolve, the need for advanced metalworking solutions becomes ever more critical.

1.2 Demand for Precision-Engineered Metal Parts

Precision is a cornerstone of the modern metalworking industry. Industries today require metal parts that meet exacting standards to ensure the functionality and safety of their products. This demand for precision-engineered components has led to significant technological advancements in metalworking machinery, particularly in stamping presses. These machines must be capable of producing complex parts with minimal tolerance for error, thereby ensuring consistency and quality in manufacturing processes.

1.3 Technological Advancements and Automation

Technological advancements are revolutionizing the metalworking industry. Automation has become a key focus, enhancing efficiency and precision in metalworking processes. Modern stamping presses are increasingly incorporating sophisticated control systems and automation features, enabling manufacturers to achieve higher productivity and accuracy. These technological innovations not only improve production efficiency but also reduce operational costs and minimize human error.

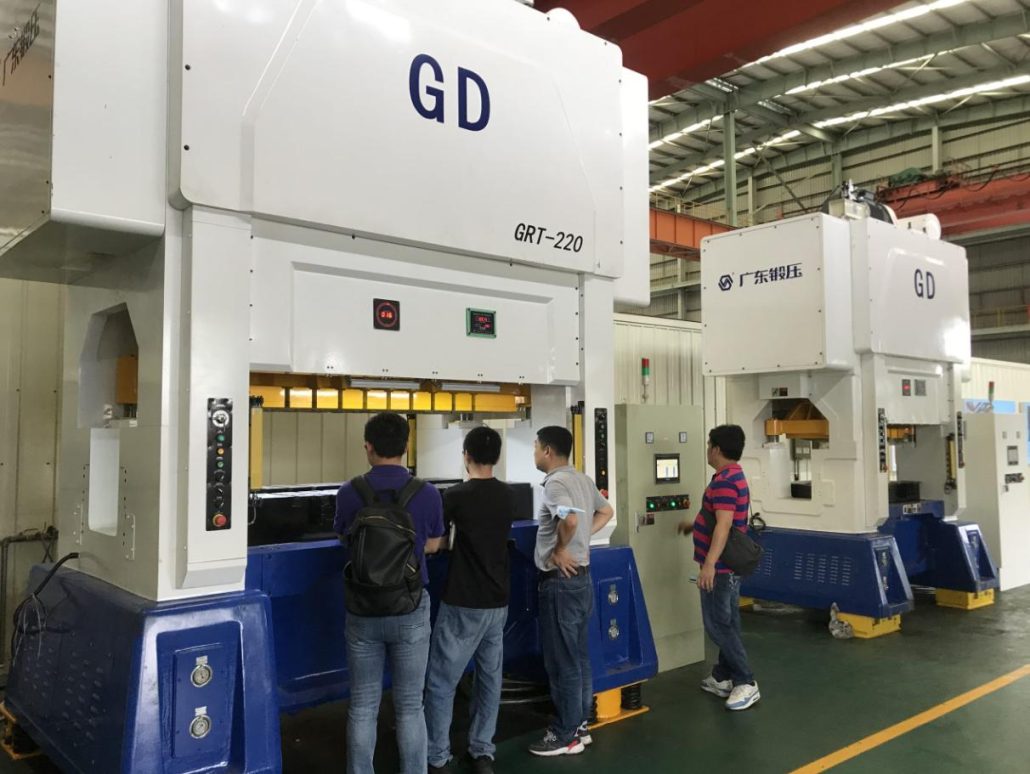

Introduction to the GK Series Knuckle Joint Press

2.1 Understanding the Role of Forging Presses

Forging presses play a crucial role in the metalworking industry, facilitating the shaping and forming of metal components through compression. Among the various types of forging presses available, the GK Series knuckle joint press stands out for its capacity and versatility. Developed by GUANG DUAN, a leading manufacturer in the Chinese metalworking industry, the GK Series offers a range of capabilities to meet the diverse needs of manufacturers.

2.2 Capacity and Specifications

The GK Series knuckle joint press provides impressive capacity, ranging from 6300KN to 25000KN, catering to a wide range of manufacturing requirements. With bolster sizes varying from 700700 to 12001200 millimeters, these presses offer flexibility in accommodating different workpiece sizes and shapes. Notably, knuckle joint presses within the range of 4000KN to 16000KN feature an integral structure, while the 12000KN press adopts a split structure design, further enhancing its performance and reliability.

Features of the GK Series Knuckle Joint Press

3.1 Advanced Clutch and Brake Systems

The GK Series knuckle joint presses incorporate advanced clutch and brake systems to ensure precise and efficient operation. For instance, the GK-630 series utilizes a pneumatic wet integrated friction clutch brake, while the GK-800 to GK-2500 models adopt a pneumatic dry split friction clutch brake. These systems provide reliable control over the press’s movement, allowing for smooth operation and accurate forming of metal components.

3.2 Crank Toggle Mechanism

The mechanism employed in the GK Series knuckle joint presses is a crank toggle one, offering several advantages in metalworking applications. One notable feature is the ability of the slide to dwell at the bottom dead center for approximately 1/18 cycle, enabling precise control over the forming process. This mechanism enhances the press’s capability to produce high-quality components with consistent accuracy.

3.3 Precision Engineering

Precision is paramount in the metalworking industry, and the GK Series knuckle joint presses deliver exceptional accuracy. The die height indicator’s accuracy display value is an impressive 0.01mm, ensuring precise adjustments for optimal forming results. This level of precision is essential for meeting strict quality standards and producing components that meet the exact specifications of customers.

Key Needs in the Metalworking Industry

4.1 High Precision and Accuracy

a. Ensuring Consistent Quality

In the metalworking industry, achieving high precision and accuracy is crucial. Chinese Stamping Press for Metalworking Industry must produce parts that meet stringent quality standards consistently. This requires machinery equipped with advanced control systems that can precisely manage the stamping process, ensuring each component meets the desired specifications.

b. Reducing Material Waste

High precision in stamping processes also contributes to reducing material waste. By ensuring that each part is accurately formed, manufacturers can minimize the amount of scrap material generated during production. This not only lowers material costs but also supports sustainability efforts by reducing waste.

c. Meeting Industry Standards

Different industries have varying standards for metal parts, and stamping presses must be versatile enough to meet these diverse requirements. High precision and accuracy are essential for compliance with these standards, ensuring that components are fit for use in critical applications, such as in the automotive and aerospace industries.

4.2 Cost-Effectiveness

a. Balancing Performance and Investment

One of the primary challenges in the metalworking industry is balancing high performance with cost-effective solutions. Chinese Stamping Press for Metalworking Industry 2024 need to deliver exceptional performance while being affordable. This balance ensures that manufacturers can invest in advanced machinery without compromising their budget, enabling them to remain competitive in the market.

b. Efficient Production Methods

Cost-effectiveness is also achieved through efficient production methods. Modern stamping presses are designed to optimize the production process, reducing cycle times and increasing output. This efficiency translates into lower operational costs and higher profitability for manufacturers.

c. Long-Term Financial Benefits

Investing in cost-effective stamping presses offers long-term financial benefits. Durable and reliable machinery reduces the need for frequent repairs and replacements, minimizing maintenance costs. Additionally, efficient machines contribute to lower energy consumption, further reducing operational expenses.

4.3 Versatility

a. Adapting to Diverse Applications

The metalworking industry requires versatile machinery capable of handling a wide range of applications. Stamping presses must be adaptable to different tasks, from forming simple components to manufacturing complex parts. This versatility allows manufacturers to cater to various industries, expanding their market reach.

b. Supporting Multiple Industries

Versatile 2024 Chinese Stamping Press for Metalworking Industry are essential for supporting multiple industries. Whether it’s automotive, aerospace, electronics, or construction, these machines must meet the specific needs of each sector. This adaptability ensures that manufacturers can respond to changing market demands and diversify their product offerings.

c. Customizable Features

To achieve versatility, modern stamping presses come with customizable features. Manufacturers can configure the machinery to suit specific production requirements, enhancing their ability to produce a diverse range of metal parts. This customization capability is a significant advantage in a dynamic and competitive market.

4.4 Energy Efficiency

a. Lowering Operational Costs

Energy efficiency is a critical factor in the metalworking industry. Stamping presses that consume less energy contribute to lower operational costs, making production more economical. Energy-efficient machinery is particularly important as energy prices continue to fluctuate, impacting manufacturing expenses.

b. Minimizing Environmental Impact

In addition to cost savings, energy-efficient stamping presses also minimize environmental impact. By reducing energy consumption, these machines help decrease greenhouse gas emissions and support sustainable manufacturing practices. This aligns with global efforts to combat climate change and promotes a positive corporate image.

c. Sustainable Production Methods

Sustainability is becoming increasingly important in the metalworking industry. Energy-efficient stamping presses enable manufacturers to adopt more sustainable production methods, reducing their carbon footprint. This focus on sustainability not only benefits the environment but also meets the growing consumer demand for eco-friendly products.

4.5 Durability and Low Maintenance

a. Ensuring Long-Term Operation

Durability is a key requirement for stamping presses in the metalworking industry. Machinery that can withstand the rigors of continuous operation ensures long-term reliability and productivity. Durable presses reduce the likelihood of breakdowns, minimizing downtime and maintaining production schedules.

b. Minimizing Downtime

Low maintenance requirements are crucial for maximizing uptime. Best Chinese Stamping Press for Metalworking Industry designed with robust components and advanced engineering needs less frequent maintenance, reducing the risk of unexpected interruptions. This reliability is vital for maintaining a steady production flow and meeting delivery deadlines.

c. Cost-Effective Maintenance

When maintenance is necessary, it should be cost-effective and straightforward. Stamping presses with easy-to-access components and user-friendly maintenance procedures simplify the upkeep process. This reduces maintenance costs and ensures that the machinery remains in optimal working condition.

GUANG DUAN: Leading the Charge with Chinese Stamping Presses

5.1 Advanced Technology and Precision Engineering

a. State-of-the-Art CNC Systems

GUANG DUAN stands at the forefront of the stamping press industry, leveraging advanced technology to deliver exceptional performance. Their presses are equipped with state-of-the-art CNC systems, providing precise control over the stamping process. This high level of precision ensures the production of complex metal components with minimal error margins, significantly reducing material waste.

b. Innovative Solutions

Innovation is a hallmark of GUANG DUAN’s approach. They continuously develop new solutions to meet the evolving needs of the metalworking industry. By integrating the latest technological advancements, GUANG DUAN ensures that their stamping presses offer superior performance and reliability.

c. Enhancing Product Quality

The precision engineering behind GUANG DUAN’s stamping presses directly translates into higher product quality. Manufacturers using these presses can produce parts that meet exacting standards, ensuring that their products are reliable and fit for use in demanding applications. This focus on quality helps manufacturers build a reputation for excellence in their respective industries.

5.2 Meeting Industry Demands

a. High Precision and Accuracy

GUANG DUAN’s stamping presses are designed to meet the industry’s demand for high precision and accuracy. The advanced control systems in their machinery ensure that each part is manufactured to exact specifications, reducing waste and improving overall production efficiency.

b. Cost-Effective Solutions

Understanding the importance of cost-effectiveness, GUANG DUAN offers stamping presses that balance high performance with affordability. Their machines are designed to optimize production processes, reducing operational costs and providing long-term financial benefits for manufacturers.

c. Versatility and Customization

Versatility is another key feature of GUANG DUAN’s stamping presses. These machines are adaptable to various metalworking tasks and can be customized to meet specific production requirements. This flexibility allows manufacturers to cater to diverse market needs and enhance their competitive edge.

5.3 Commitment to Sustainability

a. Energy-Efficient Machinery

GUANG DUAN is committed to sustainability, offering energy-efficient stamping presses that lower operational costs and reduce environmental impact. Their machines are designed to consume less energy, supporting eco-friendly manufacturing practices and helping manufacturers achieve their sustainability goals.

b. Durable and Reliable Design

The durability and low maintenance requirements of GUANG DUAN’s stamping presses ensure long-term, reliable operation. This durability minimizes downtime and maintenance costs, providing manufacturers with a dependable solution for their metalworking needs.

c. Supporting Sustainable Production

By providing energy-efficient and durable machinery, GUANG DUAN supports sustainable production methods. Manufacturers using their presses can reduce their carbon footprint and contribute to environmental conservation efforts, aligning with global sustainability trends.

Conclusion

GUANG DUAN’s Chinese Stamping Press for Metalworking Industry is at the forefront of the metalworking industry, offering advanced technology, precision engineering, and cost-effective solutions. As the global metalworking market continues to expand, the demand for high-quality, versatile, and sustainable machinery is more critical than ever. GUANG DUAN’s commitment to innovation and excellence ensures that its stamping presses meet the stringent requirements of today’s metalworking industry, providing manufacturers with the tools they need to succeed in a competitive market.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us