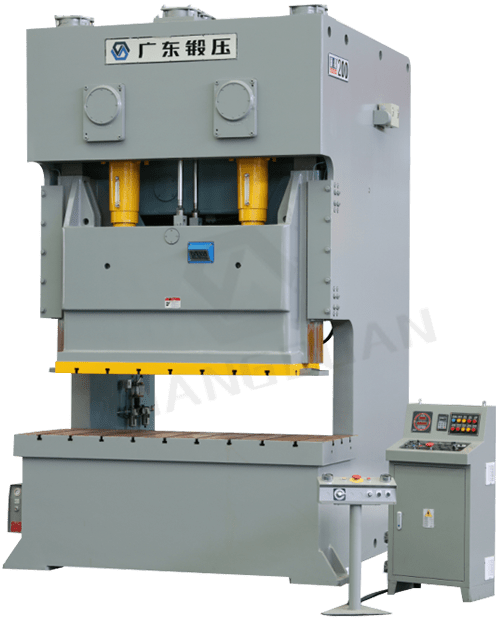

PRODUCT

Hydraulic and Mechanical Press Machine Manufacturer

High tension cast iron and internal stress relief ensure precision, high stability and great ability of shock resistance of Guangduan’s high speed presses. Our forging presses are mainly applied in rotor, stator and those metal parts that in extreme demand of effective productivity.

WHY CHOOSE US

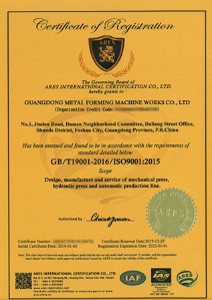

Founded in 1958, with more than 60 years experience in developing cutting-edge technology in metal stamping, GUANGDUAN has become the largest forging and press machine manufacturer in Southern China. It integrates R&D, manufacturing, and service of hydraulic press machines, mechanical press machines, and forging press. Also it is known as a national high-tech enterprise and one of the fifty backbone press machines enterprises in Guangdong province. With over 800 experienced employers, a large quantity of advanced processing and inspection equipment and a principle of serving customers wholeheartedly, we keep forging ahead towards providing metal stamping solutions and service to customer satisfaction.

SOME FUN FACE ABOUT OUR BUSINESS

Industrial Experience

Facility Size

Engineers & Technicians

Production Equipment

CASE

An automated servo hydraulic press machine production line composed of 12 large gantry servo hydraulic press machines with specifications of 12000kN, 8000kN and 6300kN are completed on time and customer’s quality target, with our team’s concerted efforts and working hard.

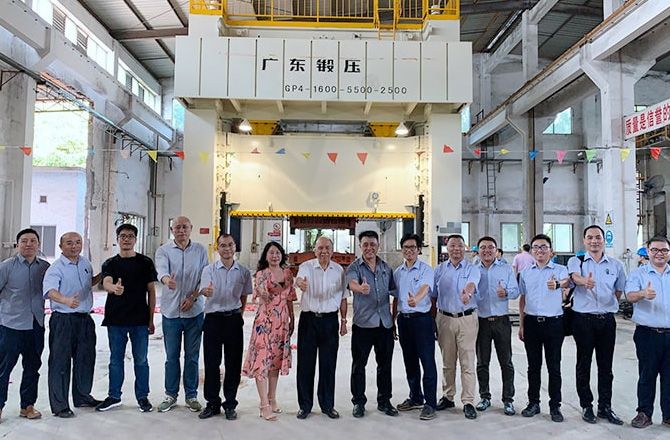

GP4-1600-5500-2500 straight side four-point precision mechanical press machine provides efficiency production capacity for large-scale automobile parts toolings.

800T H-type hydraulic servo press testing with tooling for washing machine before painting and shipment

Warmly celebrate the successful delivery of GP2-1000 and GD2-800 mechanical press machines for the production of large-scale automotive metal parts

NEWS

You can get the latest industry information from here.

Maximize Efficiency: A Deep Dive into the Hydraulic Press Working Principle

28/03/2024

The introduction of the hydraulic press: A hydraulic press, sometimes referred to as a shop press, is a device that applies a substantial amount of compressive force to a workpiece using hydraulic cylinders. Because of their ability to bend, straighten, flatten, or stamp the workpiece, hydraulic presses are useful instruments for a variety of industries. ... Read more

The Indispensable Tool: Hydraulic Press for Metal

26/03/2024

What does hydraulic press for metal? The metalworking industry relies heavily on hydraulic presses because they provide a flexible and effective solution for a variety of manufacturing projects. With the help of hydraulic pressure, these strong machines can shape and manipulate metal work pieces into the necessary shapes. Hydraulic press for metal offers the strength and accuracy ... Read more

GUANGDUAN: Reliable Hydraulic Press Machine Suppliers Worldwide

26/03/2024

Choosing the Right Partner: An Overview of Providers of Hydraulic Press Machines The strong compressive force is produced by hydraulic cylinders in hydraulic presses, which are extremely potent devices. They are extensively employed in many different sectors for a variety of tasks, such as fabrication, assembly, and maintenance. This in-depth manual will cover hydraulic presses’ ... Read more

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us