Is Stamping Machine for Sale in Metalworking Industry Worth Investment for Your Business?

The metalworking industry stands as a cornerstone of modern manufacturing, encompassing a vast array of processes aimed at shaping raw metal materials into finished products. From automotive parts to household appliances, metalworking plays an indispensable role in numerous sectors. However, like any other industry, metalworking faces its fair share of challenges, ranging from rising material costs to limited production capacity.

Rising Material Costs and Wastage

1.1 Impact of Material Costs

The metalworking industry operates within a dynamic market influenced by fluctuating material prices. Whether it’s steel, aluminum, or other alloys, the costs of raw materials can significantly impact the bottom line of metalworking businesses. As global demand and supply chain disruptions fluctuate, companies find themselves grappling with the challenge of managing material expenses.

1.2 Minimizing Material Wastage with Stamping Machines

Traditional metalworking processes often result in considerable material wastage due to inefficient cutting, shaping, and forming techniques. However, stamping machines offer a solution to this issue. By precisely cutting and shaping metal sheets according to predefined designs, stamping machines minimize wastage, thereby reducing material costs and enhancing overall efficiency.

1.3 GUANG DUAN’s Stamping Machines: A Sustainable Solution

GUANG DUAN’s Stamping Machine for Sale in Metalworking Industry is engineered to optimize material usage, ensuring minimal wastage while maintaining high precision and quality standards. With advanced technology and customizable features, these machines empower metalworking companies to achieve greater cost-effectiveness and sustainability in their operations.

Labor Intensive Processes

2.1 Nature of Labor-Intensive Methods

Traditional metalworking methods often rely heavily on manual labor for tasks such as cutting, bending, and welding. While skilled labor is essential for ensuring quality craftsmanship, the scarcity of skilled workers poses a significant challenge for metalworking companies. Additionally, manual labor can be time-consuming and prone to errors, leading to inefficiencies and production delays.

2.2 Automating Processes with Stamping Machines

Stamping machines offer a solution to the labor-intensive nature of traditional metalworking methods by automating various production processes. By incorporating robotics and computerized systems, these machines streamline operations, reducing the reliance on manual labor and minimizing the risk of human error. This not only improves efficiency but also enhances workplace safety and productivity.

2.3 GUANG DUAN’s Innovative Approach to Automation

GUANG DUAN’s 2024 Latest Stamping Machine for Sale in Metalworking Industry leverages cutting-edge automation technologies to optimize production processes. From automated feeding systems to integrated quality control mechanisms, these machines ensure seamless operation while maximizing output and minimizing labor costs. With GUANG DUAN’s stamping machines, metalworking companies can achieve higher levels of efficiency and competitiveness in the market.

Inconsistent Quality Control

3.1 Challenges of Manual Processes

Manual metalworking processes are inherently prone to variations in quality due to human factors such as fatigue, skill level, and attention to detail. Inconsistencies in product quality not only undermine customer satisfaction but also increase the risk of defects and rework, leading to additional costs and delays.

3.2 Ensuring Consistent Quality with Stamping Machines

Stamping machines play a crucial role in ensuring consistent and precise manufacturing standards in the metalworking industry. By adhering to programmed specifications and utilizing advanced quality control mechanisms, these machines deliver uniformity and accuracy across production runs. Whether it’s intricate components or complex assemblies, stamping machines uphold the highest standards of quality and reliability.

3.3 GUANG DUAN’s Commitment to Quality Excellence

GUANG DUAN is dedicated to providing Advanced Stamping Machine for Sale in Metalworking Industry that meet the most stringent quality standards. Through rigorous testing and continuous improvement initiatives, GUANG DUAN ensures that its machines deliver unparalleled performance and reliability. With GUANG DUAN’s stamping machines, metalworking companies can uphold their reputation for excellence and meet the demands of discerning customers.

Limited Production Capacity

4.1 Constraints of Traditional Methods

Traditional metalworking methods often struggle to keep pace with the growing demands of the market. Whether it’s due to limited manpower, outdated equipment, or inefficient processes, companies face challenges in scaling up production to meet customer needs in a timely manner.

4.2 Enhancing Efficiency with Stamping Machines

Stamping machines offer a solution to the limitations of traditional metalworking methods by enhancing production capacity and efficiency. With their high-speed operation, rapid tool changes, and multi-station capabilities, these machines enable companies to increase output while maintaining quality and consistency. This scalability is essential for staying competitive in today’s fast-paced business environment.

4.3 GUANG DUAN’s Versatile Solutions for Production Optimization

GUANG DUAN offers a range of 2024 Stamping Machine for Sale in Metalworking Industry designed to cater to diverse production needs. Whether it’s small-scale fabrication or mass production, GUANG DUAN’s machines are equipped with features that maximize throughput and minimize downtime. By investing in GUANG DUAN’s stamping machines, metalworking companies can unlock new levels of productivity and profitability.

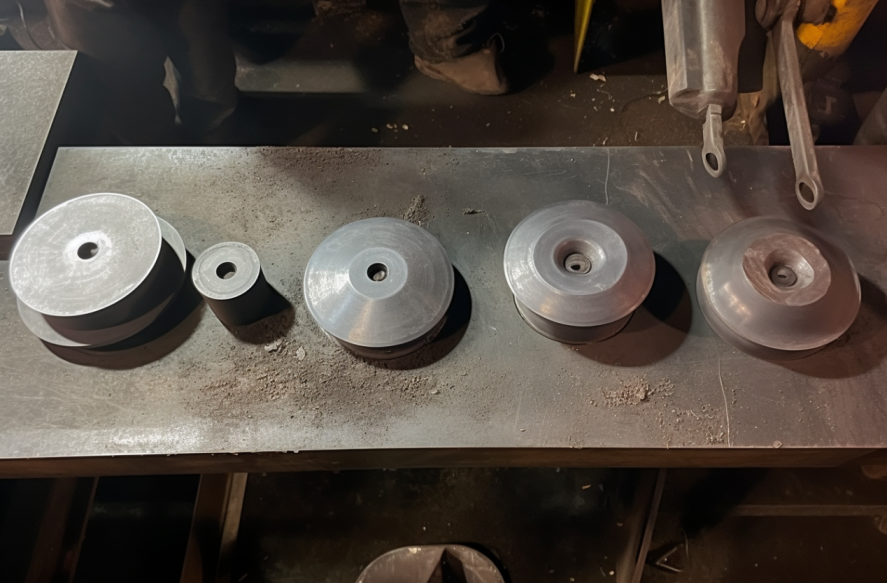

Revolutionizing Metalworking with Closed Type Single Point Forge Press Machine JH31 Series

5.1 Monolithic Box-Type Structure

The body of the forge press machine JH31 series is constructed using a monolithic box-type structure, ensuring exceptional rigidity and stability during operation. This robust design, combined with advanced engineering techniques, provides the foundation for high-precision stamping and pressure setting processes.

5.2 Mechanical Die Height Adjustment

Equipped with a mechanical die height adjustment mechanism, the JH31 Series enables quick and easy die calibration. The digital display further enhances accuracy, allowing operators to precisely control the stamping process with minimal effort. This feature streamlines setup procedures, reducing downtime and maximizing productivity.

5.3 Hydraulic Overload Protection

For enhanced safety and reliability, the JH31-400/630/800 models of the forge press machine incorporate a hydraulic overload protective device. This mechanism safeguards the machine and its components against excessive force, minimizing the risk of damage or malfunction during operation. With built-in safety measures, operators can work with confidence, knowing that the machine is equipped to handle challenging stamping tasks.

5.4 PLC and Pneumatic Control

The integration of PLC (Programmable Logic Controller) and pneumatic control systems offers unparalleled flexibility and efficiency. The JH31 Series provides three-stroke specifications: continuous stroke, single stroke, and micro-motion, allowing operators to tailor the machine’s performance to suit specific production requirements. This combination of advanced control technologies enhances operational precision and responsiveness, resulting in superior outcomes.

5.5 Automated Production Capabilities

To further optimize production workflows, the forge press machine can be equipped with optional features such as photo-electric protection, automatic feeding devices, and uncoiling leveling devices. These enhancements enable automated production processes, reducing manual intervention and increasing throughput. The compact structure, sleek design, and logical layout contribute to an ergonomic and user-friendly operating environment.

Conclusion

In conclusion, Stamping Machine for Sale in Metalworking Industry represents a game-changing innovation in the metalworking industry, offering solutions to some of its most pressing challenges. From minimizing material wastage and labor costs to ensuring consistent quality and enhancing production capacity, these machines empower companies to thrive in an increasingly competitive market landscape. As a leading manufacturer of stamping machines, GUANG DUAN remains committed to driving innovation and excellence in the metalworking industry, enabling businesses to achieve their goals and surpass customer expectations.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us