Choosing the Right Metalworking Equipment for Middle East Market

Metalworking Equipment For Middle East Market buyers demand reliability, tight precision, and responsive service that hold up in tough conditions while keeping total cost under control.

Why Metalworking Equipment For Middle East Market Matters

From Guangduan’s shop floor to your production line, we see the same core requirements across the region: stable uptime, repeatable accuracy, and changeovers that do not burn hours. Heat, dust, and long duty cycles can test any machine. Project work jumps from prototypes to volume runs, so equipment must shift modes quickly without drifting out of spec. Skills depth varies from site to site, which makes intuitive controls and clear diagnostics essential.

That is why selection cannot stop at tonnage or a headline speed number. The right platform protects accuracy as the hours rack up. It keeps operators safe and productive. It offers a control system that helps, not hinders, the work. At Guangduan, we design around structural rigidity, guidance that locks the slide in alignment, and servo control that blends speed with fine pressure control. When you choose Metalworking Equipment For Middle East Market, you should expect more than a spec sheet – you should expect process stability from day one and predictable yield month after month.

We also look at the ownership picture. Downtime costs more than parts. A press that is easy to lubricate, quick to align, and simple to set up pays for itself in fewer scrapped parts and less waiting. This is the benchmark we use when we recommend a solution, whether you are a Tier-1 supplier or a fast-growing fabricator searching for a hydraulic press supplier in GCC.

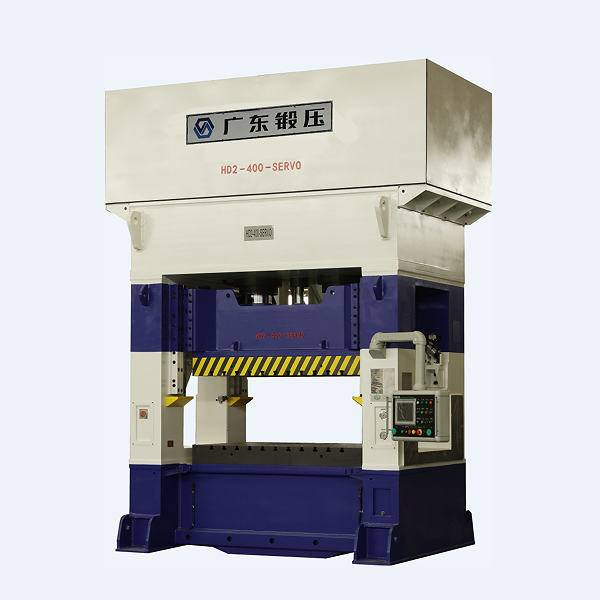

Guangduan GY2S Series for Reliable Precision

The GY2S Series Hydraulic Press is built for consistent tolerance in real factories, not just in brochures. Its clean, service-friendly layout keeps maintenance straightforward and access clear. The goal is simple: accuracy that lasts and throughput that scales.

✅ Core Engineering Choices

- Welded box frame of high-quality steel for outstanding rigidity, a clean silhouette, and easier transportation during installation or relocation.

- Steel plate welded slider with eight-sided full guide rails to keep the slide true, cycle after cycle, preserving precision and prolonging die life.

- Thin-oil continuous circulation lubrication to stabilize motion, reduce wear, and maintain smooth travel across long shifts.

- Servo closed-loop control that integrates a servo motor driver, pressure sensor, displacement sensor, and PLC – enabling high precision with low noise, low vibration, and energy savings.

- Operator-friendly intelligence: PLC + servo system + touch screen + grating ruler allow real-time digital adjustments matched to each mold and process.

- Recipe memory for up to 20 sets of mold parameters, cutting setup time and standardizing jobs across different teams or shifts.

- Layered safety: a slider locking device that can secure the slider at any position, lower-limit switch protection, two-hand anti-repeat, and parameter anti-error protection on the touch screen.

These choices are practical. The frame resists thermal and mechanical stress. The eight-sided guide keeps alignment tight even when ambient temperatures rise. The lubrication system ensures a stable film that reduces friction and early wear. And the servo loop closes the gap between command and motion, providing precise pressure and position control for sensitive forming steps.

✅ Operator-Focused Intelligence and Safety

Changeovers are where time disappears. With the GY2S interface, operators adjust parameters directly on the touch screen and store proven settings for the next run. A press setup that once took multiple trials becomes a repeatable routine. Saved recipes also support quality documentation; you can trace the exact setting set used on an order. Safety is built in from hardware to logic, so teams can focus on output, not workarounds. For buyers looking for precision metal forming solutions in UAE, this combination aligns with daily shop demands and long-term lifecycle goals – exactly the fit you want when selecting Metalworking Equipment For Middle East Market.

Partnership and ROI with Guangduan

Guangduan was founded in 1958 and has grown into the largest forging and pressing equipment manufacturer in South China, integrating R&D, manufacturing, and service. We are a national high-tech enterprise and a backbone equipment maker in Guangdong Province. Our research platform includes a Postdoctoral Research Station, the Guangdong Forging Equipment Engineering Technology R&D Center, a Provincial Enterprise Technology Center, and the Guangdong Key Laboratory of Metal Forming Processing and Forging Equipment Technology. We have undertaken nearly 60 science and technology projects at national, provincial, municipal, and district levels. This is not a badge wall; it is the engine behind steady product improvement and faster technical support.

Capability also shows up in how we build. Our team includes over 100 engineers and technicians, with 13 holding senior titles, including a professor-level senior engineer. We operate more than 200 major production machines, nearly 100 large precision CNC units, and over 1,000 advanced measurement and testing devices such as large CMMs and laser tracking instruments. We also hold a second-level measurement qualification. For you, this means tighter process control in manufacturing, consistent component quality, and presses that arrive ready to work.

✅ What does that translate to on your floor?

- Faster ramp-up: stored parameters and guided setup shorten first-article time.

- Lower scrap risk: slide guidance and servo loop help keep forming conditions inside the window.

- Predictable maintenance: continuous thin-oil lubrication and a rigid frame reduce unplanned stops.

- Operator confidence: clear screens, logical menus, and robust safety reduce training time.

In short, when you invest in Metalworking Equipment For Middle East Market, you invest in uptime, accuracy, and a partner who can support both. Guangduan’s approach is to pair equipment delivery with training and responsive service. We help teams standardize settings, document best practices, and maintain stable yields as order volumes grow. That is how ROI is built – one stable cycle at a time.

Call to Action: Planning a line upgrade or a new cell? Let’s talk. Request a process review, ask for a demo of the GY2S Series Hydraulic Press, or share a target part and tolerance. Guangduan will help you match the right press to your molds, materials, and quality goals – and build a clear path from first setup to dependable, scalable production with Metalworking Equipment For Middle East Market.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us