Why Your Powder Metallurgy Process Needs a Hydraulic Press Machine Upgrade

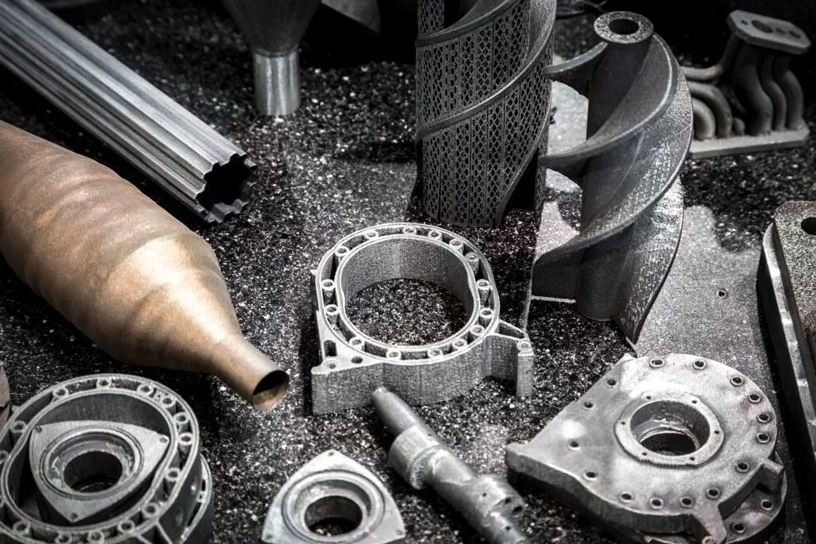

Powder Metallurgy Hydraulic Press Machine upgrades are changing how PM parts are made. Tighter control brings higher density, cleaner edges, and fewer cracks. Energy use falls. Changeovers speed up. Noise and vibration drop. Your dies last longer. Your Cp/Cpk climbs. Yet many lines still run on older presses and live with hidden waste. What if the bottleneck is not your powder or tooling, but the press itself? At GUANGDUAN, we see the same pattern across factories. The fix is simpler than most expect – and the gains arrive fast. Ready to see where the losses hide? The data may surprise you.

The Case For Upgrading Your Powder Metallurgy Hydraulic Press Machine

Many PM cells still run reliably, yet quietly limit performance. The signs are familiar: variability in green density, premature die wear, micro-cracks after ejection, and lengthy setup for new SKUs. Each issue erodes margins and on-time delivery. A modern Powder Metallurgy Hydraulic Press Machine addresses these pain points with tighter control and smarter operation.

First, precision. Stable force and position control improve powder flow, compaction, and ejection. This reduces lamination and edge chipping. Parts leave the press with repeatable dimensions, so downstream sizing and machining fall in both time and cost. Second, availability. Newer hydraulic and control architectures reduce vibration and noise, which protects tooling and cuts unplanned stoppages. Third, adaptability. Shorter setup times and recipe storage let small batches run economically, so you can serve more customers without idle presses.

For manufacturers who quote tight tolerances, a precision powder compaction press is now a competitive requirement. It secures Cp/Cpk, improves traceability, and supports growth into stainless, soft magnetic, and high-hardness applications.

- What Changed On The Factory Floor?

Customers expect consistent parts, but development cycles are shorter. Material mixes evolve. Energy prices swing. A servo-controlled hydraulic press for powder metallurgy brings real-time digital control to this reality. When your press adapts quickly, you launch faster and ship with confidence.

Inside The GUANGDUAN Advantage

Our approach starts with structure. The main body uses a high-quality steel, welded box construction for high rigidity, clean lines, and easier transport. The slider is also a steel plate, welded box design. It rides on an eight-sided full-guide rail system to hold precision under load and retain that precision over time. You get long-term alignment that protects dies and delivers consistent compaction.

Lubrication matters for longevity. A thin-oil continuous circulation system keeps friction low and motion smooth. This reduces temperature spikes, keeps seals healthy, and lowers maintenance time.

Control is the core. A servo closed-loop system – integrating a servo motor driver, pressure sensor, displacement sensor, and PLC – governs every cycle. You benefit from high precision, low noise, low vibration, and improved energy efficiency. On the HMI, a touch screen with a grating ruler enables real-time digital adjustment to match different molds and processes. Up to 20 sets of mold parameter recipes can be stored and recalled, which cuts changeover time and setup error.

Safety is built in. A slider locking device secures the slider at any position to prevent accidental movement. Lower-limit switch protection, two-hand anti-repeat operation, and multi-level parameter anti-error checks on the touch screen add layered safety without slowing the work.

In practice, that stack of features translates into measurable outcomes for powder metallurgy:

• Higher and more uniform green density across complex geometries

• Fewer cracks and delamination during ejection, lowering scrap rate

• Better dimensional stability that reduces secondary sizing or machining

• Faster changeovers using stored recipes for recurring SKUs

• Lower noise and vibration, extending die life and boosting OEE

- Designed For Precision Powder Compaction

A rigid frame and eight-side guidance keep the punch path true. Sensors track displacement and pressure in real time, so compaction follows the profile you program – not a best guess. Thin-oil circulation smooths the cycle. The result is repeatability. Your operators see stable ejection forces, consistent fill, and clean part release. Quality managers see tighter distributions. Finance sees lower cost per good part.

Implementation Roadmap And ROI

An upgrade yields value when it is planned around your products and people. At GUANGDUAN, we align scope to outcomes, not just specifications.

Begin with a baseline. Audit your current press data: density spread, ejection force trends, die change intervals, and energy use per part. Identify top defect modes and their true cost. Then pilot. Select one or two representative components – ideally those with multi-level geometry or tight flatness requirements. Transfer parameters to the new Powder Metallurgy Hydraulic Press Machine, run DOEs, and lock in the recipe.

Operator adoption is crucial. The touch screen makes adjustments intuitive, but we pair it with targeted training so teams can set pressure profiles, monitor displacement, and use recipe controls with confidence. Maintenance teams gain clear routines around oil circulation checks and sensor calibration, which keeps the system at peak performance.

Data integration closes the loop. Connect press data to your quality system for live SPC. When density proxies drift, alarms guide correction before defects ship. Over the first months, you should see scrap fall, tool life extend, and takt stabilize. Energy per good part drops as vibration and rework decline.

✅ Expected wins many customers observe:

- 15 – 30% reduction in scrap tied to ejection and delamination issues

- Noticeable improvement in Cp/Cpk for critical dimensions

- Shorter changeovers with stored mold/process recipes

- Lower operator fatigue thanks to reduced noise and vibration

If your roadmap includes harder powders, higher densities, or tighter tolerances, an upgrade is the safest way to scale. It equips your line for the next generation of PM parts without adding complexity to the shift.

Final Words

Ready to benchmark your cell? Contact GUANGDUAN for a no-obligation application review and an on-press demonstration. We’ll map your key parts to a modern Powder Metallurgy Hydraulic Press Machine, share a density uniformity snapshot, and propose a practical rollout plan. We keep forging ahead towards providing metal stamping solutions and service to customer satisfaction – now let’s bring that same momentum to your powder metallurgy line.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us