-

Home / Products / Hydraulic Press / Four Column Double Action Hydraulic Press Machine YA28 Series

OUR PRODUCT

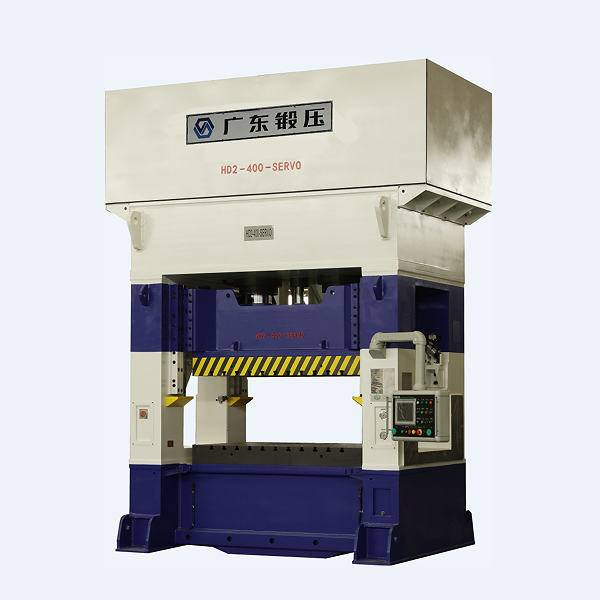

Four Column Double Action Hydraulic Press Machine YA28 Series

YA28 Series Four Column Double Action Hydraulic Press mainly for thin plate deep drawing, forming, aligning, bending, and folding. It is widely used in hardware and electric appliance, stainless steel ware, electronic component, and motor manufacturing industries.

Four column and three beam structure, cylinder, and cylinder rods are chrome plated after thermal refining and polishing. High rigidity, good guidance performance, and fast idle running.

What is a Four Column Hydraulic Press Machine?

The four column hydraulic press machine is an oil pump that delivers hydraulic oil to the integrated cartridge valve block. The hydraulic oil is distributed to the upper or lower chamber of the cylinder through each check valve and relief valve, and the cylinder is moved from a high position. A hydraulic press is a device that uses liquid to transmit pressure. When a liquid transmits pressure in an airtight container, it obeys Pascal’s law.

Features

- The main hydraulic components and seals are world-renowned for superior performance and reliable quality.

- The working process can choose fixed position or fixed pressure mode, as well as maintain pressure and delay.

- Working pressure and stroke can be adjusted within the range to meet different processing requirements.

- Centralized button, adjustable/single cycle operation type selectable, with two-hand synchronization and anti-two-hand duplication safety function.

Working principle

The hydraulic transmission system of the four-column hydraulic press consists of a power mechanism, a control mechanism, an executive mechanism, an auxiliary mechanism, and a working medium. The power mechanism usually uses an oil pump as a power mechanism, generally an integrated oil pump. In order to meet the speed requirements of the actuator, one oil pump or multiple oil pumps can be selected.

No information.

Specification

|

Unit |

YH28-275 |

YH28-425 |

YH28-500 |

YH28-700 |

YH28-900 |

YH28-1200 |

||

|

Nominal capacity |

kN |

2750 |

4250 |

5000 |

7000 |

9000 |

12000 |

|

|

Main Cylinder Capacity |

kN |

1750 |

2750 |

3000 |

4500 |

6000 |

8000 |

|

|

Lower cylinder capacity |

kN |

1000 |

1500 |

2000 |

2500 |

3000 |

4000 |

|

|

Main Cylinder Stroke |

mm |

560 |

620 |

620 |

710 |

710 |

800 |

|

|

Bottom Cylinder Stroke |

mm |

300 |

300 |

350 |

350 |

350 |

350 |

|

|

Main Cylinder Downward |

mm/s |

300 |

250 |

200 |

220 |

220 |

250 |

|

|

Main Cylinder Working Speed |

mm/s |

17/24 |

15/23 |

15/23 |

10.5/27.5 |

10/25 |

8/15 |

|

|

Main Cylinder Return Speed |

mm/s |

225 |

250 |

210 |

160 |

190 |

220 |

|

|

Lower cylinder ejecting speed |

mm/s |

60 |

90 |

55 |

60 |

60 |

60 |

|

|

Upper ejector stroke length |

mm |

220 |

220 |

220 |

220 |

220 |

350 |

|

|

Upper ejector capacity |

kN |

35 |

35 |

35 |

45 |

45 |

200 |

|

|

Bolster Area |

LR inside column |

mm |

1000 |

1120 |

1250 |

1400 |

1400 |

1600 |

|

FB to edge |

mm |

1120 |

1250 |

1400 |

1600 |

1600 |

1600 |

|

|

Pin holes area (LF*FB) |

mm |

930*770 |

940*800 |

110*930 |

1330*1200 |

1330*1200 |

1350*1100 |

|

|

Main cylinder hydraulic pressure |

mm |

1000 |

1200 |

1250 |

1300 |

1300 |

1300 |

|

|

Main cylinder hydraulic pressure |

MPa |

19 |

20 |

22 |

20.5 |

24.5 |

23 |

|

|

Lower cylinder hydraulic pressure |

MPa |

24 |

25 |

24 |

24 |

25 |

25 |

|

|

Servo motor |

kw |

22 |

37 |

37 |

45 |

55 |

75 |

|

|

Weight |

kg |

9000 |

14500 |

23500 |

31000 |

35000 |

55000 |

|

|

Overall dimension |

LR |

mm |

2160 |

2300 |

1660 |

1860 |

1860 |

2500 |

|

FB |

mm |

1980 |

2100 |

1430 |

1630 |

1650 |

1650 |

|

|

H |

mm |

3900 |

4345 |

4480 |

4740 |

4800 |

6000 |

|

|

Bolster to ground |

mm |

1195 |

1335 |

1435 |

1465 |

1530 |

2150 |

|

|

Oil volume |

L |

900 |

1000 |

1000 |

1600 |

1600 |

2000 |

|

|

|

External hydraulic |

External hydraulic |

External hydraulic |

External hydraulic |

||||

YA28(YH28)100-200

YA28-350/450/700

YA28-275/425/500/700

YA28(YH28) SERIES

Ejector positions should rotate 90 degrees for Model YH28 (Y28)-200.

Dotted lines T-slot in Fig.3 is model YA28-700.

Ejector layout configuration is for reference, subject to latest drawing.

Bolster and Slide Dimension

|

Model |

A |

B |

C |

D |

E |

F |

G |

H |

M |

N |

O |

P |

R |

S |

T |

L |

Center bolt hole |

|

YH28-100 |

18 |

30 |

14 |

30 |

225 |

310 |

140 |

25 |

48 |

32 |

— |

— |

— |

— |

— |

— |

M36 |

|

Y28-120B |

18 |

30 |

14 |

30 |

225 |

280 |

140 |

25 |

42 |

32 |

— |

— |

— |

— |

— |

— |

M36 |

|

YH28-150 |

18 |

30 |

14 |

30 |

275 |

280 |

140 |

25 |

48 |

32 |

— |

— |

— |

— |

— |

— |

M60X2 |

|

Y28-200 |

22 |

37 |

16 |

38 |

305 |

285 |

150 |

25/30 |

52 |

32 |

— |

— |

— |

— |

— |

— |

M60X2 |

|

YH28-200 |

22 |

37 |

16 |

38 |

305 |

285 |

150 |

27.5 |

52 |

32 |

— |

— |

— |

— |

— |

— |

M60X2 |

|

Y28-350 |

28 |

46 |

20 |

50 |

381 |

400 |

— |

— |

58 |

40 |

63.5 |

12 |

63.5 |

10 |

— |

— |

M60X2 |

|

Y28-450 |

28 |

46 |

20 |

50 |

381 |

350 |

— |

— |

76 |

40 |

63.5 |

14 |

63.5 |

12 |

— |

— |

M60X2 |

|

Y28-700 |

28 |

46 |

20 |

50 |

381 |

430 |

— |

— |

90 |

50 |

63.5 |

16 |

63.5 |

12 |

381 |

280 |

M60X2 |

|

YA28-275 |

22 |

37 |

16 |

38 |

240 |

425 |

— |

— |

100 |

40 |

80 |

11 |

80 |

9 |

— |

— |

M60X2 |

|

YA28-425 |

28 |

46 |

20 |

50 |

240 |

470 |

— |

— |

100 |

40 |

80 |

11 |

80 |

9 |

— |

— |

M60X2 |

|

YA28-500 |

28 |

46 |

20 |

50 |

240 |

535 |

— |

— |

128 |

40 |

80 |

13 |

80 |

11 |

480 |

300 |

M60X2 |

|

YH28-700 |

28 |

46 |

20 |

50 |

320 |

515 |

— |

— |

102 |

50 |

80 |

16 |

80 |

14 |

480 |

320 |

M60X2 |

|

YA28-900 |

36 |

60 |

25 |

60 |

— |

— |

— |

— |

— |

— |

— |

— |

— |

— |

— |

— |

M60X2 |

|

YA28-1200 |

36 |

60 |

25 |

60 |

— |

— |

— |

— |

— |

— |

— |

— |

— |

— |

— |

— |

M60X2 |

Remarks: Specifications are subject to change without notice.

No information.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us