Servo Hydraulic Press Explained: How Eight-Sided Guides Ensure Precision

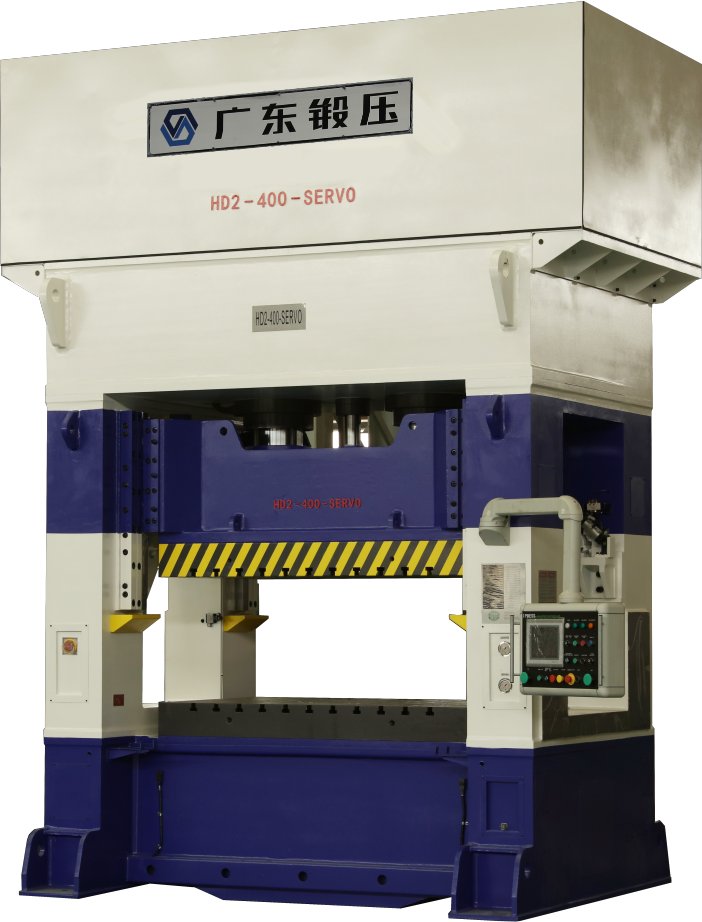

A servo hydraulic press is only as precise as the way its slide is guided. At Guangduan, we design presses for shops that need consistent, repeatable forming every shift. In this article, we explain how eight-sided guides stabilize the slide, how closed-loop servo control improves accuracy and efficiency, and why structure, lubrication, and safety features matter to your bottom line.

Why a Servo Hydraulic Press Needs Better Guidance

Metal forming loads are not always centered. Deep drawing, bending, and progressive dies often pull the slide off-center. When guidance is weak, the slide can yaw or tilt. Dies wear unevenly. Parts drift out of tolerance. Scrap rises.

A servo hydraulic press with a strong guidance system resists these forces. It keeps the slide moving straight and parallel to the bolster. That is why we use an eight-sided full guide rail design. It holds precision and retains it over time. The result is stable forming, longer die life, and fewer adjustments on the line.

The Eight-Sided Guide: Precision You Can See

Eight-sided full guides surround the slide on all sides with a large bearing surface. Compared with simple gibs, this layout distributes side loads more evenly. It reduces clearances that lead to twist, and it maintains alignment during both high-pressure forming and rapid approach.

What does that mean for your production?

• Smoother slide motion under asymmetric loads.

• Better parallelism between slide and table during contact.

• Lower risk of die galling and chipped punches.

• More consistent thickness and geometry on drawn parts.

The slide itself is a steel-plate welded box. It resists deformation under load. The frame is a welded, high-quality steel box as well. This combination gives the guidance the rigid base it needs to work. You get a press that stays tight, holds straightness, and looks clean on the floor, with easy transport and installation.

Closed-Loop Control in a Servo Hydraulic Press

Precision mechanics need a smart control system. Our servo hydraulic press ties a servo motor driver to pressure and displacement sensors and a PLC. The system measures, decides, and corrects in real time. It controls position, pressure, and speed as separate, precise variables. That is how you hold tolerance without chasing settings shift after shift.

Key benefits you will feel on the floor:

• High precision: Position and pressure are monitored and corrected continuously.

• Low noise and low vibration: The servo drives on demand, not at full flow all the time.

• Energy saving and environmental protection: Power follows the cycle, cutting waste.

• Faster setup: A touch screen with a grating ruler feedback lets you tune motion profiles directly.

You can store up to 20 sets of mold parameters in the system. Call up a recipe for a repeat job, and you are ready to run. Real-time digital adjustment on the HMI lets you fine-tune cushion pressure, approach speed, dwell time, and return speed according to each die and process. That means less trial stock, fewer press stops, and a shorter learning curve for new parts.

Built to Run: Structure and Lubrication

A rigid structure keeps accuracy stable. We build the main frame as a high-quality steel welded box. It is strong and resists deflection. The slide is also a welded box. Together, they create a solid path for force from slide to foundation. For you, that means predictable forming and less rework.

Lubrication is the quiet partner in precision. We use a thin oil continuous circulation system on the guides. A protective oil film cuts friction on the guides and reduces wear. It maintains smooth travel and pulls heat away during extended operation. Ongoing lubrication also prevents low-speed stick-slip – essential for a slow, controlled approach in draw or coining tasks.

Safety and Uptime: Confidence Built In

Operator safety and tool protection reinforce each other. We bake safety into the machine so your team can run with confidence and your dies are well protected.

• Slider locking device: Holds the slide anywhere to avert unintended drops during setup, changeover, or maintenance.

• Lower limit switch protection: Prevents overstroke and protects your dies and cushions.

• Two-hand anti-repetition control: Enforces safe, two-hand initiation and disallows unintended repeating.

• Anti-error protection on the touch screen: Input validation and access control reduce operator mistakes.

These safeguards strengthen compliance and underpin your EHS goals. They also lessen unplanned downtime from mishandling or mis-set limits. When safety is embedded, productivity follows.

Where Eight-Sided Guides Meet Real Production

An eight-sided guide and a closed-loop servo system make a strong pairing. The guide keeps the slide true. The control makes the motion exact. Together, they help in:

• Automotive brackets and housings that need tight flatness.

• Appliance panels where surface quality and draw depth must repeat.

• Electronics enclosures that require precise embossing and pierce location.

• General stampings where off-center loads are common.

In many shops, the immediate gains show up as steadier first-off parts, fewer shims in the die, and faster buyoff on new jobs. Over time, you will also see slower guide wear thanks to continuous lubrication, and lower daily energy draw because the servo only works when you ask it to.

Choose Guangduan: Next Steps

Guangduan builds servo hydraulic press solutions that translate engineering into practical value for your team. We combine an eight-sided full guide rail, a rigid welded frame, thin-oil circulation lubrication, and a servo closed-loop control with touch-screen operation and 20-recipe storage. You get accuracy you can measure, setup you can repeat, and safety you can trust.

Call to Action

Share the part drawing plus cycle timing and pressure details. Our team will craft a motion profile and guidance plan.

Obtain an energy and acoustic comparison between your current press and a Guangduan servo hydraulic press.

Arrange a live trial or remote demo to see digital adjustments, recipe recall, and slide lock functionality demonstrated.

Ready to raise precision and cut waste? Contact Guangduan today. We will help you turn stable guidance and smart control into better parts, longer die life, and a calmer, more efficient press line.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us