Custom Forging Machines Deliver Power and Precision to Small-Scale Workshops

Custom forging machines are changing how small workshops work. They fit on a modest floor. Yet they deliver force once found only in giant plants. More makers now see forging as an option, not a distant dream. A shop can forge bicycle cranks today, switch molds, and press dental tools tomorrow. Setup is quick. Maintenance stays low. Margins rise.

The market moves fast. Clients want custom shapes next week, not next month. A compact forge lets you answer that call with confidence. In this article we explore key features, cost paths, and real stories from users. Follow along to see how a smart machine can forge strong growth for your business.

Why Small Workshops Need Big Tools

Rising Demand for Precision and Flexibility

Small workshops face growing pressure to deliver high-precision parts. Clients want shorter lead times and flexible designs. To stay competitive, these workshops must adapt fast. Precision and consistency are no longer optional—they are the standard.

Challenges of Traditional Forging Methods

Old forging methods are large, noisy, and hard to control. They often require more manpower and space. Maintenance costs are high. For small workshops, these issues slow down production and reduce profits.

Custom Forging Machines as the Ideal Solution

Custom forging machines solve these problems. They are designed to fit smaller spaces but still deliver strong, consistent results. Their precision and ease of use make them perfect for today’s flexible manufacturing needs. With smart controls and fast setup, they are becoming the first choice for small-scale production.

GUANGDUAN: Powering Precision Since 1958

60+ Years of Forging Innovation

Since 1958, we have focused on forging and pressing machines. With over 60 years of experience, we lead the way in forging technology in South China. Our journey is built on constant improvement and technical strength.

Strong R&D and Technical Expertise

We believe in innovation. That’s why we have built top research centers, including a postdoctoral research station and several provincial labs. Our team has more than 100 engineers, including senior-level experts. Every custom forging machine we make is backed by deep research and solid engineering.

Trusted Leader in the Industry

Today, we are proud to be recognized as a national high-tech enterprise. We are one of Guangdong’s backbone manufacturers. Our goal is to help more workshops benefit from advanced forging equipment. With strong after-sales service and expert support, we stand behind every machine we deliver.

What Makes Custom Forging Machines Unique

Modular Design for Every Need

Our custom forging machines are not one-size-fits-all. Each model is built with a modular structure. That means you can choose the features that match your production needs. Whether you need hot forging or cold forming, we offer the right setup.

Smart Controls and Sensors for Better Output

We add CNC systems and smart sensors to every machine. These features give you control over every detail—from heat levels to pressure timing. You get stable output, reduced waste, and faster changeovers.

Compact Size, Big Performance

Custom forging machines from GUANGDUAN are compact but powerful. They fit small workshop floors without losing strength. Even in tight spaces, you can run complex jobs with high force and exact control. This makes them perfect for workshops with limited space and high standards.

Applications that Make a Difference

Custom Parts for Bikes and Cars

Custom forging machines are used in many small-scale factories. One common use is in the bicycle and automotive industries. These machines produce parts like gears, pedals, and brackets with high accuracy. In these industries, strong and lightweight components are a must. Custom forging machines help deliver both.

Tooling for Medical, Electronics, and Hardware

Small workshops also use custom forging machines to make precise tools for medical and electronic devices. They can switch quickly between different molds. That means one machine can produce a range of parts, from surgical tools to connectors and fasteners. This flexibility is key in these fast-moving sectors.

Winning Big with Small Batches

In today’s market, clients want fast, flexible production. Custom forging machines allow small workshops to meet these demands. They can handle low-volume, high-mix production. This means shorter lead times, better quality, and happy customers. That’s how small operations win big orders.

GUANGDUAN‘s Custom Forging Machines in Action

Hot and Cold Forging for All Needs

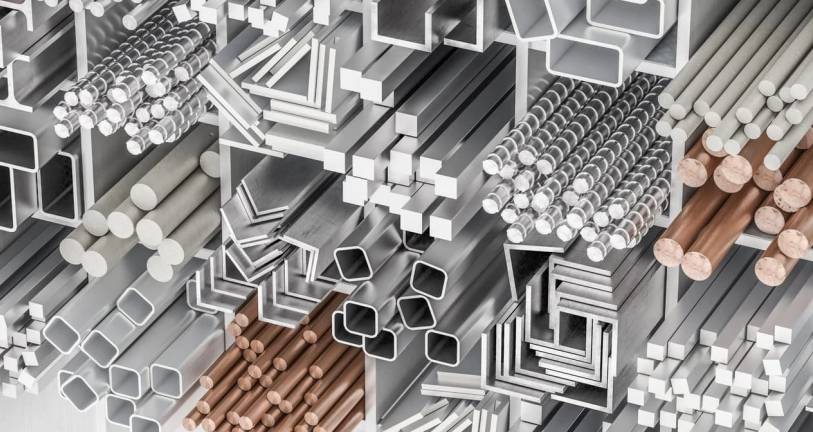

At GUANGDUAN, we offer both hot and cold forging systems. Each one is designed for different types of materials and shapes. Our machines are used to form steel, aluminum, copper, and more. With the right setup, you can handle everything from soft parts to hard metals.

Knuckle-Joint and Hydraulic Drive Options

Our custom forging machines come with different drive systems. For precision parts, we offer knuckle-joint presses. For strong, steady pressure, we provide hydraulic systems. You can choose what works best for your product and production goals.

Energy Savings and Clean Operation

Our machines are made to be efficient. They use less energy than older systems. They are also quieter, which helps create a better work environment. With fewer errors and less scrap, you save on materials too. That means more profit with every part you make.

Choosing the Right Custom Forging Machine for Your Workshop

Understand Your Workshop‘s Needs

Before buying a custom forging machine, think about what you need. How much force do you need? What materials do you work with? How much space do you have? Choose the right machine by checking tonnage, stroke speed, and floor size.

Know the Differences Between Machines

There are different types of custom forging machines. Mechanical presses are fast and good for simple parts. Hydraulic presses give better control for complex shapes. Screw presses are strong and reliable. Each one has its strengths. Picking the right type helps you work smarter.

We Offer More Than Just Machines

At GUANGDUAN, we don’t just sell machines. We help you choose the right one. We offer full support—design consultation, installation, training, and after-sales service. We want your workshop to run smoothly from day one.

The Future Forged Today

Driven by R&D and Innovation

We believe innovation is the future. That’s why we keep investing in research and development. Our custom forging machines are built with the latest technology. Our engineers work every day to make them smarter, faster, and more efficient.

Expanding Across Borders

We are not only strong in China. GUANGDUAN is growing worldwide. Our goal is to bring our custom forging machines to more markets. We want more small workshops around the world to benefit from our machines.

Why Now Is the Right Time to Invest

The industry is changing fast. Workshops that invest in custom forging machines today will lead tomorrow’s supply chains. With better tools and smarter systems, small factories can do big things. At GUANGDUAN, we are ready to help you take that step.

Forge Ahead with GUANGDUAN – Precision Tools for Growing Workshops

Join the many small manufacturers already boosting productivity and precision with GUANGDUAN’s custom forging machines. Whether you’re producing auto parts, medical tools, or specialty hardware, we have the right solution for you. Contact us today for a free consultation and discover how our machines can transform your workshop into a high-performance production hub. Let’s forge your future—together.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us