Why Manufacturers Are Racing to Invest in High-Speed Stamping Press Technology

High-speed stamping press machines are reshaping modern factories. They strike metal with incredible speed. Each stroke is precise. Each cycle saves time. Workers see parts flow like water. Managers watch costs drop in real time. Customers feel the difference in product strength. The press becomes the heartbeat of the line. In many plants, it is the first tool switched on each morning. Few technologies have moved from test floor to core asset so fast.

Why are manufacturers racing to own one? The answer is simple. They want more output without adding floor space. They want quality that meets strict global standards. They want machines that talk to sensors and software. A modern press tells operators when a die needs care. It logs every hit for traceability. It knows the exact force of the last run. This data feeds lean programs. It cuts scrap. It supports predictive maintenance. The shop becomes quieter, cleaner, and safer. In short, investment today protects profits tomorrow.

The New Manufacturing Race

Why Speed Matters in Today‘s Manufacturing Environment

In today’s global market, speed is everything. Manufacturers must deliver parts faster than ever before. Delays lead to lost orders and unhappy customers. A high-speed stamping press helps factories meet these tight deadlines. It boosts output without needing more machines or space.

Demand for Tighter Tolerances and Clean Finishes

Modern products require perfect fit and finish. Tiny errors can lead to large failures. A high-speed stamping press ensures consistent quality with each stroke. It forms complex shapes with high accuracy. This helps companies meet industry standards and customer expectations.

Enter the High-Speed Stamping Press

The high-speed stamping press is transforming production lines. It combines speed and precision in one powerful machine. As industries evolve, more manufacturers are choosing this technology. It allows them to stay competitive, efficient, and reliable.

What Is a High-Speed Stamping Press and Why It Matters

How It Works

A high-speed stamping press shapes metal parts through rapid force. The machine pushes a die against a workpiece. This process repeats hundreds of times per minute. The press’s motion is smooth and stable, reducing waste and improving output.

Types of High-Speed Stamping Presses:

- Mechanical presses use flywheels for strong, repeatable force.

- Hydraulic presses offer flexible control and handle thicker materials.

- Servo presses allow precise speed and position control.

- Pneumatic presses use air pressure and work well in clean environments.

Each type serves different needs and industries.

Core Advantages

A high-speed stamping press runs faster than standard machines. It handles high volumes with fewer errors. The process is repeatable, so every part matches the last. This improves efficiency and saves costs. Manufacturers can produce more with less downtime.

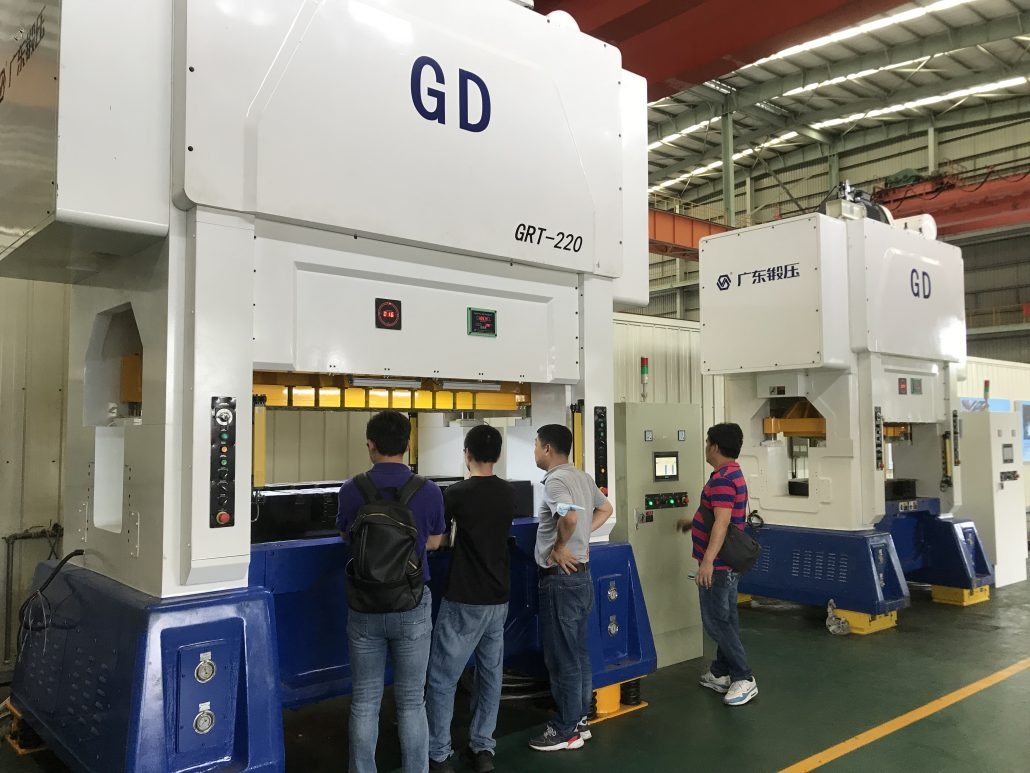

GUANGDUAN: Driving Innovation in Stamping Press Technology

A Legacy of Excellence

Founded in 1958, we have over 60 years of industry experience. Our machines support global industries, from automotive to electronics. Our long history proves our reliability and commitment to quality.

R&D Leadership

We believe in innovation. That’s why we’ve built research centers and labs focused on forging technology. Our team includes more than 100 engineers. They work every day to improve high-speed stamping press performance. Our focus on R&D helps us stay ahead of market demands.

Production Powerhouse

Our factory is over 30,000 square meters. We own over 200 sets of major equipment. This includes CNC machines, crankshaft grinders, and gear cutters. We also have advanced inspection tools like laser trackers and 3D measurement systems. These resources help us build high-speed stamping presses that are precise, durable, and ready for modern factories.

High-Speed Press Applications Across Industries

Automotive Manufacturing

The automotive industry demands fast and accurate production. A high-speed stamping press is ideal for making engine parts, body panels, and EV components. It shapes strong metal parts with high repeatability. This helps automakers build safer, lighter, and more efficient vehicles.

Electronics & Appliances

Electronics and appliances need small, precise parts. A high-speed stamping press can produce thin connectors, frames, and covers at a high rate. These machines reduce scrap and ensure clean finishes. They are perfect for mass production with tight tolerances.

Aerospace & Defense

In aerospace and defense, quality is critical. Parts must be light, strong, and exact. A high-speed stamping press helps form complex components from special alloys. It delivers consistent shapes with minimal error, supporting mission-critical applications.

GUANGDUAN‘s High-Speed Stamping Press Solutions

Tailored Machines for Complex Needs

We design each high-speed stamping press to match customer needs. Our machines support various die sizes and stroke lengths. Whether it’s small electronic parts or large automotive panels, our solutions handle it all with ease and speed.

Built for Precision

We use high-end CNC machines to ensure each press is made with care. Our high-speed stamping press systems include real-time sensors and smart controls. These features help monitor accuracy and make instant adjustments during production.

Key Investment Benefits for Manufacturers

Boosting Output Without Expanding Floor Space

Factory space is expensive. A high-speed stamping press can increase output without needing more area. These machines produce more parts per hour using the same footprint. This helps manufacturers grow without expanding their facilities.

Lowering Costs Through Automation and Energy Efficiency

Our presses support automation, which reduces manual labor. Fewer hands are needed on the line. At the same time, modern high-speed stamping press designs consume less power. This cuts energy bills while keeping production fast.

Supporting Smart Factories with Data and Integration Capabilities

Our high-speed stamping press machines are ready for Industry 4.0. They collect and share data in real time. This helps companies track performance, plan maintenance, and improve decision-making. The press becomes a smart part of the factory system.

Why GUANGDUAN Is the Partner of Choice

Global Support and After-Sales Network

We believe service is as important as the machine itself. Our after-sales team responds quickly to customer needs. We support clients across the globe with training, spare parts, and troubleshooting. Every high-speed stamping press comes with our full commitment.

Strategic Vision for Global Markets

We are proud to meet international standards like ISO 9001. Our high-speed stamping press machines are trusted in markets across Asia, Europe, and beyond. We focus on quality and innovation to stay globally competitive.

GUANGDUAN‘s Roadmap for Intelligent, Connected Presses

We continue to invest in R&D. Our goal is to build smarter, faster, and greener high-speed stamping press solutions. With over 60 years of experience, we look forward to leading the next generation of metal forming technology.

Ready to Boost Your Production with GUANGDUAN?

Invest in a high-speed stamping press that delivers speed, precision, and long-term value. At GUANGDUAN, we offer tailored solutions backed by over 60 years of expertise. Whether you’re in automotive, electronics, or aerospace, our machines are built to elevate your production line.

Contact us today to learn how our high-speed stamping press technology can help you stay ahead in the competitive manufacturing world.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us