-

Home / Products / Hydraulic Press / Hydraulic Press GY2S Series

OUR PRODUCT

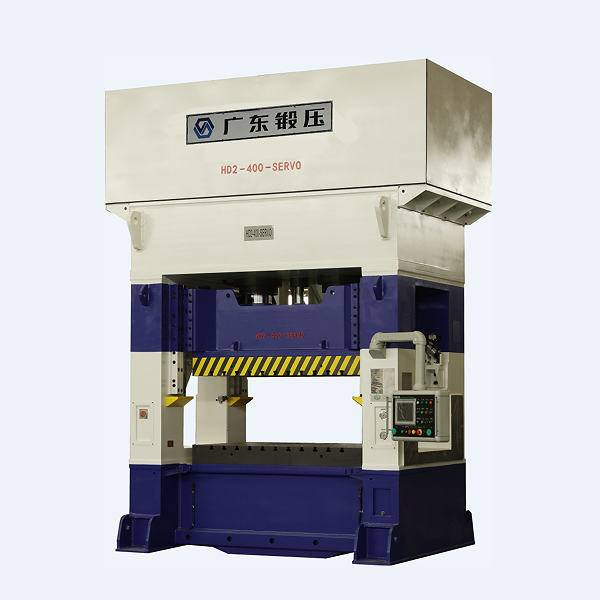

Hydraulic Press GY2S Series

The main structural parts of the fuselage are made of high-quality steel welded box structure, which has good rigidity, beautiful appearance and easy transportation.

The slider is a steel plate welded box structure, which adopts eight-sided full guide rail guide, which has good precision and precision retention.

Thin oil continuous circulation lubrication system.

GY2S SERIES HYDRAULIC PRESS

The main structural parts of the fuselage are made of high-quality steel welded box structure, which has good rigidity, beautiful appearance and easy transportation.

The slider is a steel plate welded box structure, which adopts eight-sided full guide rail guide, which has good precision and precision retention.

Thin oil continuous circulation lubrication system.

The servo closed loop control system is composed of servo motor driver, pressure sensor displacement sensor and PLC. High precision, low nose, low vibration, energy saving and environmental protection.

Intelligent control and high operability using PL a servo system + touch screen + grating ruler control mode real-time digital adjustment can be realized by touch screen according to different molds and production processes, and 20 sets of mod parameter settings can be stored in the system.

High security. The machine is equipped with a slider locking device that looks the sider at any position to prevent the block from accidentally sliding. It is equipped with the protection of the lower limit switch and the anti-repetition of the two-handed hands. It has multi -level protection such as anti-error protection in the parameter setting of the touch screen.

No information.

GY2S SERIES PARAMETERS

| Unit | GY2S-300 | GY2S-400 | GY2S-500 | GY2S-800 | GY2S-1000 | GY2S-1250 | GY2S-1600 | GY2S-2000 | ||

| Main cylinder capacity | kN | 3000 | 4000 | 5000 | 8000 | 10000 | 12500 | 16000 | 20000 | |

| Slide stroke length | mm/s | 600 | 600 | 700 | 800 | 1200 | 1200 | 1500 | 1500 | |

| Main cylinder fast approach speed | mm/s | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | |

| Main cylinder pressing speed (variable speed) | mm/s | 15/45 | 15/40 | 15/40 | 15/30 | 15/30 | 15/30 | 15/30 | 15/30 | |

| Main cylinder pressing speed (variable speed) | mm/s | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | |

| Main cylinder pressing speed (variable speed) | mm | 1000 | 1000 | 1200 | 1200 | 1600 | 1600 | 2000 | 2000 | |

| Bolster area Slide area | LR | mm | 1300 | 2000 | 3000 | 3500 | 4000 | 4500 | 4600 | 5000 |

| FB | mm | 1100 | 1200 | 2000 | 2000 | 2200 | 2500 | 2600 | 2800 | |

| Optional: Movable bolster | Quantity of movable bolster | Workbench structure Forward backward: The left and right shifts and the number are selected by the customer. | ||||||||

| Bolster to ground | mm | — | — | — | 700 | 750 | 750 | 750 | 750 | |

| Load of movable bolster | ton | — | — | — | 35 | 40 | 40 | 45 | 45 | |

| Moving speed | m/min | — | — | — | 1.5-12 | 1.5-12 | 1.5-12 | 1.5-12 | 1.5-12 | |

| Pin lifting capacity | kN | — | — | — | 15 | 15 | 15 | 15 | 15 | |

| Pin lifting stroke length | mm | — | — | — | 160 | 160 | 160 | 160 | 160 | |

| Cushion capacity | kN | 1000 | 1500 | 2000 | 3000 | 4000 | 4000 | 5000 | 5000 | |

| Cushion stroke length | mm | 300 | 300 | 300 | 300 | 400 | 400 | 400 | 400 | |

| Cushion pad size | LR | mm | 900 | 1500 | 2320 | 2620 | 3220 | 3520 | 3670 | 4120 |

| FB | Mm | 700 | 850 | 1420 | 1420 | 1570 | 1720 | 1870 | 2170 | |

| Cushion ejecting speed | mm/s | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

| Servo motor | kW | 37 | 55 | 61 | 80 | 145 | 160 | 195 | 235 | |

Remarks:Specifications are subject to change without notice

No information.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us