Key Factors When Selecting a Hydraulic Press Manufacturer

Hydraulic Press Manufacturer selection is no longer a simple price comparison – it is a strategic choice that will shape your productivity, quality, and long-term profitability. For many factories, the press is at the center of metal forming, and when it stops or produces unstable parts, the whole line feels the impact.

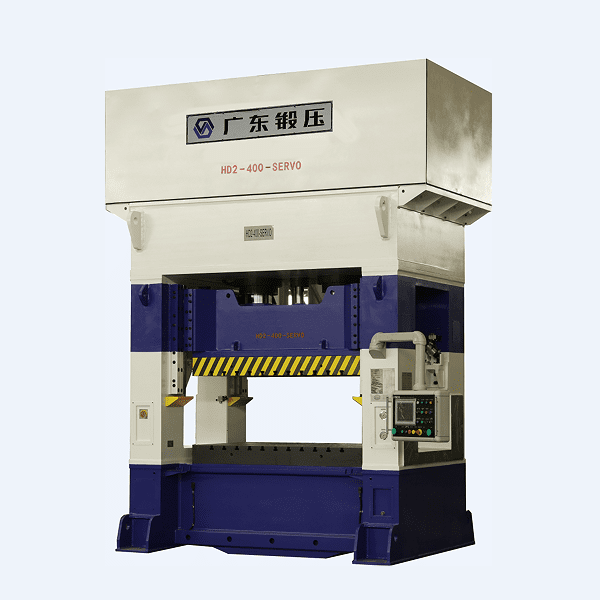

(GY2S Series)

Understanding Your Production Reality

Before you compare one Hydraulic Press Manufacturer with another, it is important to look honestly at your own production reality. Many problems in stamping and forming do not start with the press itself. They come from a mismatch between the machine and the job.

If you run high-strength or special materials, you need stable tonnage, rigid frames, and precise slide guidance. If you are drawing thin plate for sinks, housings, or covers, you need smooth speed control and accurate pressure holding. When these needs are not clear, companies often buy a “standard” press that looks strong on paper but struggles in daily work.

As a manufacturer founded in 1958, GUANGDUAN has seen this pattern repeat over more than 60 years. Customers tell us about:

•unexpected cracks during deep drawing

•uneven wall thickness on thin plates

•noise and vibration that tire operators and damage tools

•slow changeovers that waste time between different parts

(YA28 Series)

These pain points usually come from three gaps: the wrong press structure, insufficient control precision, and limited automation or recipe management. That is why we design series such as the GY2S hydraulic press with a welded box frame, high-rigidity slider, and eight-sided full guide rails. The goal is simple: keep deflection low, keep alignment stable, and keep your die working in the right window for longer.

When you review your current line, ask practical questions: How often do you adjust the press to chase quality? How much time do you lose when changing tools? How many operators do you need around each press? Honest answers to these questions will guide you toward the right Hydraulic Press Manufacturer more than any brochure can.

What to Look for in a Hydraulic Press Manufacturer

Once your needs are clear, the next step is to evaluate the Hydraulic Press Manufacturer behind the machine. A press is a long-term asset. You are not just buying steel and hydraulics; you are choosing a partner that will support you for 10 – 20 years.

- Proven Engineering Capabilities

A serious manufacturer should have a strong engineering foundation, not only assembly capacity. At GUANGDUAN, we have built a full ecosystem for R&D and testing, including a provincial engineering technology center and a key laboratory for metal forming and forging equipment technology. More than 100 engineers and technicians work on structure design, control systems, and process optimization.

This matters because your applications are not static. New materials, new part shapes, and new quality standards keep coming. A Hydraulic Press Manufacturer with real R&D strength can adapt standard models and develop custom solutions, instead of forcing you to accept a “one-size-fits-all” machine.

- Stable, Accurate Press Performance

On the shop floor, performance is what your team sees every day. For example, the GUANGDUAN GY2S Series Hydraulic Press uses:

✅A high-quality welded box frame for rigidity and easier transportation

✅A steel plate slider with eight-sided full guide rails for precise guidance and long-term precision retention

✅A thin-oil continuous circulation lubrication system to reduce wear and help stabilize accuracy

For many customers, the real change comes from control. The GY2S Series adopts a servo closed-loop control system with servo motor, pressure and displacement sensors, and PLC. This combination allows high precision, low noise, and low vibration while saving energy. Up to 20 sets of mold parameters can be stored and recalled on the touch screen, which helps reduce setup time and human error when switching between parts.

When you compare suppliers, focus on how they guarantee accuracy over time, not only at the factory acceptance test. Ask them about their measurement and testing capability, their machining centers, and how they check frames, slides, and key components. A Hydraulic Press Manufacturer that invests in advanced measurement and gear or crankshaft grinding equipment is better prepared to deliver consistent machines to you.

Future-Proofing with Technology, Safety, and Service

A modern Hydraulic Press Manufacturer must think beyond the single press and look at your whole production lifecycle. This includes digital control, operator safety, tooling protection, and after-sales support.

In deep drawing and forming of thin plates, our YA28 and Y28 Series Four-Column Double Action Hydraulic Presses show how this works in practice. These presses use a four-column, three-beam structure, with cylinders and rods that are thermally refined, polished, and chrome plated for rigidity and smooth guidance. They are widely used for stainless steel ware, hardware, and electrical appliances where surface quality and consistent depth are critical.

Operators can choose fixed position or fixed pressure modes, hold pressure with a delay, and adjust working pressure and stroke to match each job. Safety is built in through two-hand synchronization and anti-repeat functions, plus multi-level protections in the control system. On the GY2S Series, for example, a slider locking device can hold the slide at any position to prevent unexpected movement during maintenance or die changes.

(Y28 Series)

From a buyer’s point of view, these features translate into fewer accidents, less tool damage, and higher confidence when running expensive dies or high-value materials. They also make it easier to train new operators because the interface is more intuitive and process windows are stored in the system instead of in someone’s memory.

When you choose a Hydraulic Press Manufacturer, also look at service and scale:

✅Workshop capacity (such as GUANGDUAN’s 30,000 m² processing workshop with cranes up to 125 tons)

✅Certified quality systems like ISO 9001

✅A responsive after-sales team that can support you on-site and online

These factors tell you whether the supplier can deliver large machines on time, support you during installation, and stay with you for the long term.

Finally, make sure your partner shares your vision for the future. At GUANGDUAN, our goal is to keep mastering core forging and pressing technologies, narrow the gap with global leaders, and help customers build competitive, automated factories.

If you are planning a new project or considering an upgrade, we invite you to talk with our engineering team. Share your parts, materials, and productivity targets, and we will help you choose or customize the right solution. Selecting the right Hydraulic Press Manufacturer today is your first step toward a safer, more efficient, and more profitable metal forming line tomorrow.

CONTACT US

Guangdong Metal Forming Machine Works Co., Ltd.

We are always providing our customers with reliable products and considerate services.

If you would like to keep touch with us directly, please go to contact us