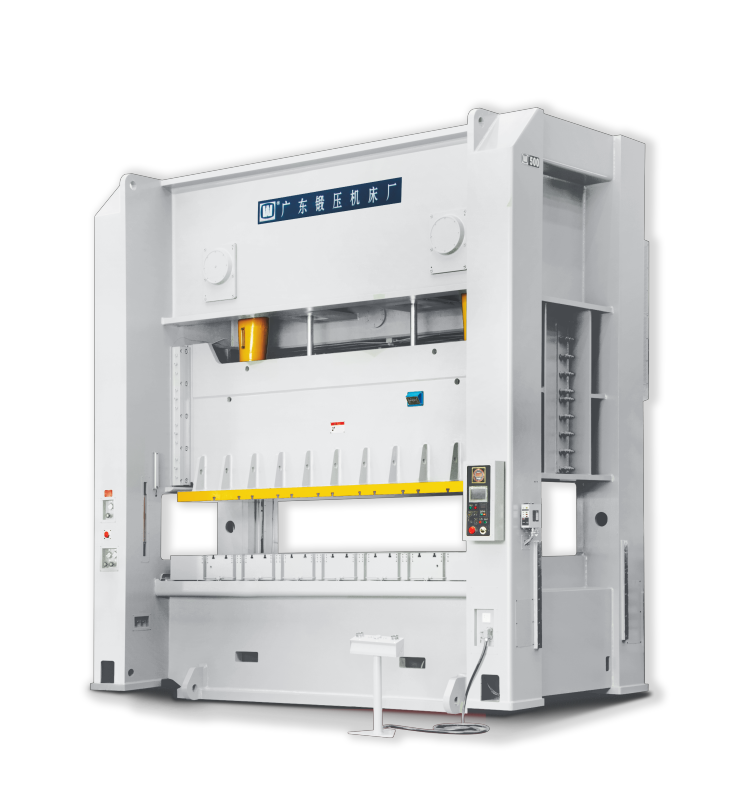

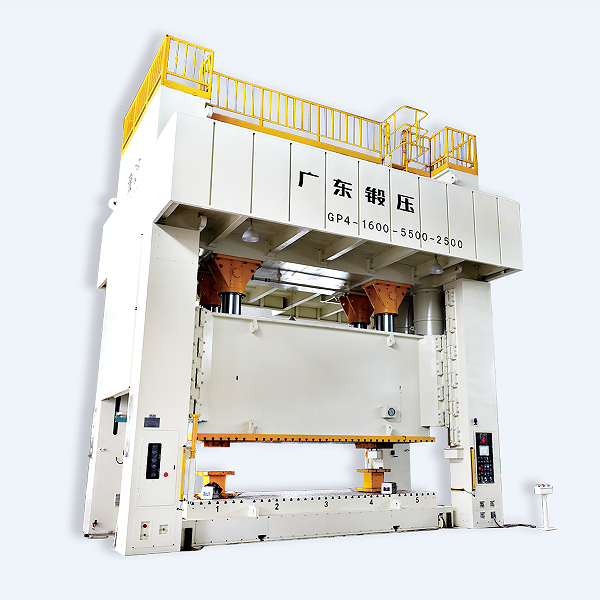

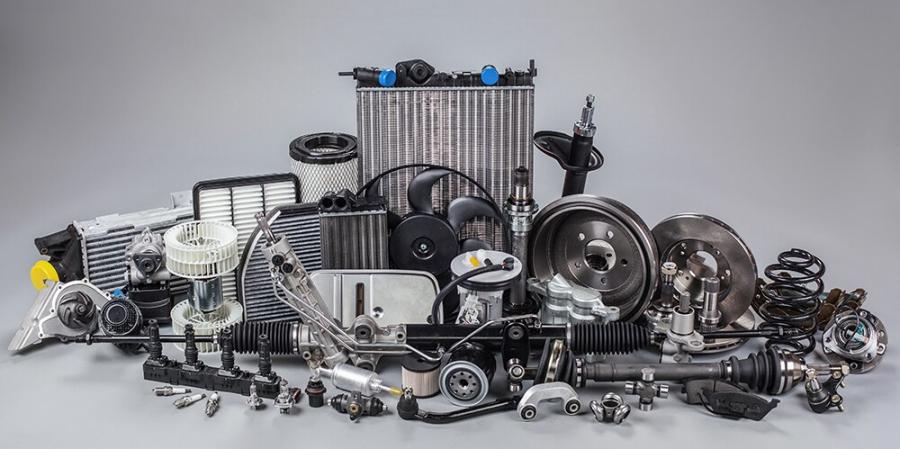

How Heavy Duty Forging Press Accuracy Impacts Final Quality

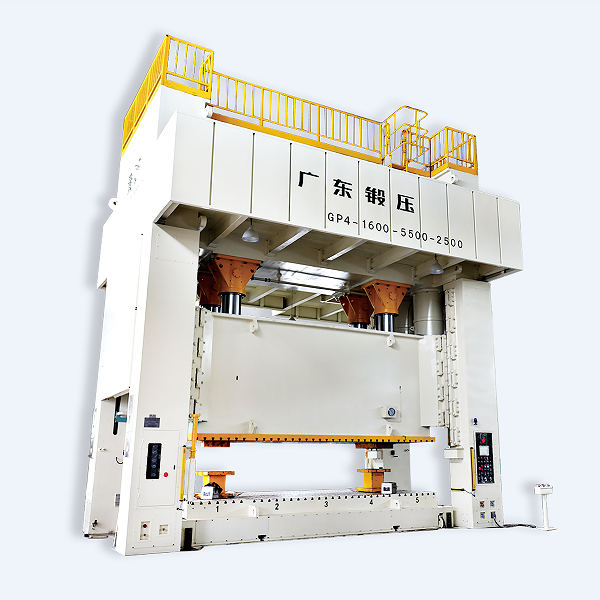

A Heavy Duty Forging Press is a machine that shapes heated metal with controlled force. It uses a rigid frame, a driven slide, and matched dies to form precise geometries. When accuracy slips, defects rise and costs follow. When accuracy holds, quality becomes repeatable. That sounds simple. But why do small alignment errors create big … Read more