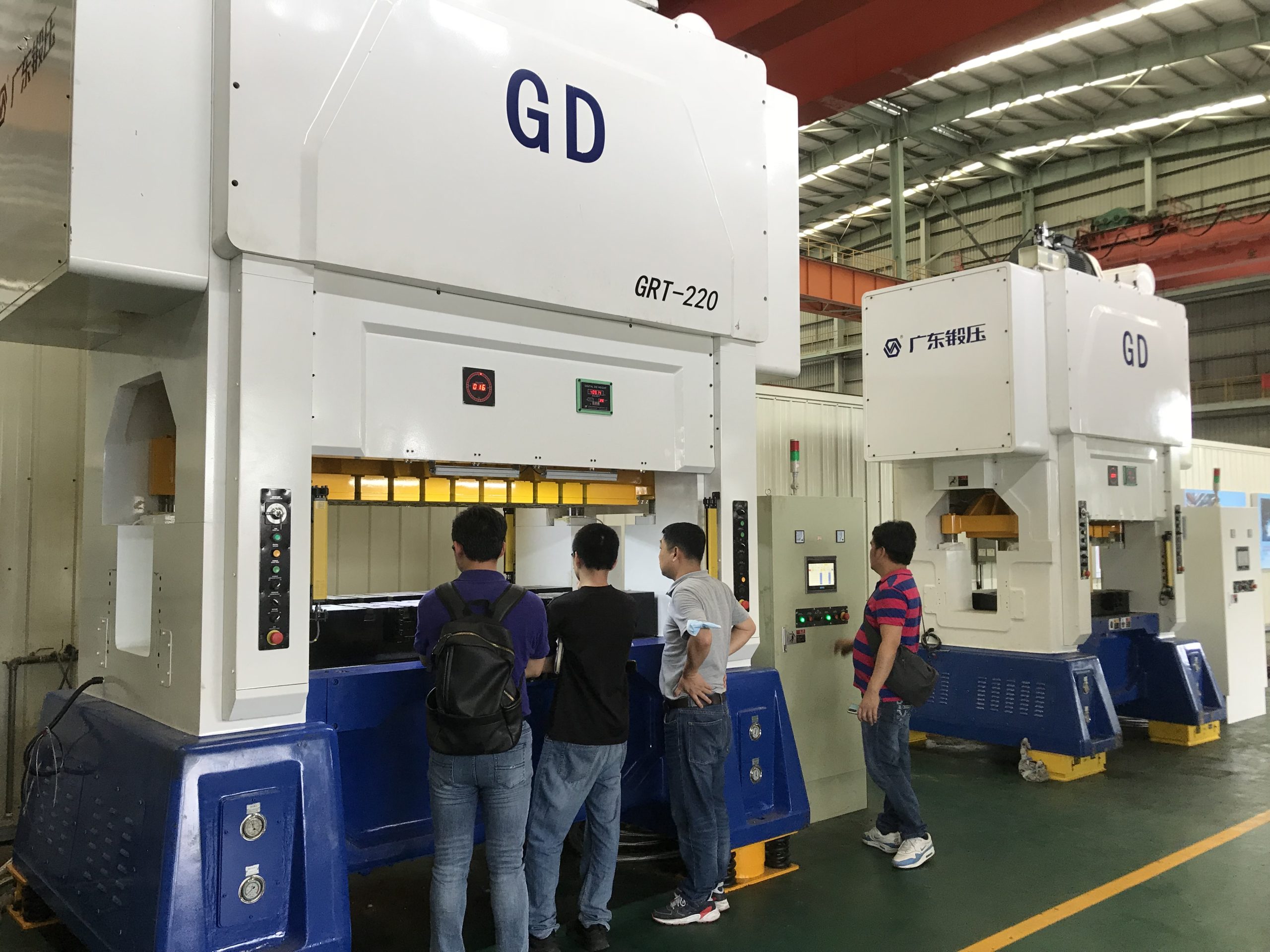

Heavy-Duty Metal Press for Aerospace Cost-Effective Quality Control

In modern aerospace plants, a forming press is no longer just “big tonnage on the shop floor.” It is a critical production platform that shapes safety-critical structures, complex skin panels, brackets, and profiles that must perform reliably in flight. A Heavy-Duty Metal Press for Aerospace therefore has to behave like a precision system: stable under demanding … Read more